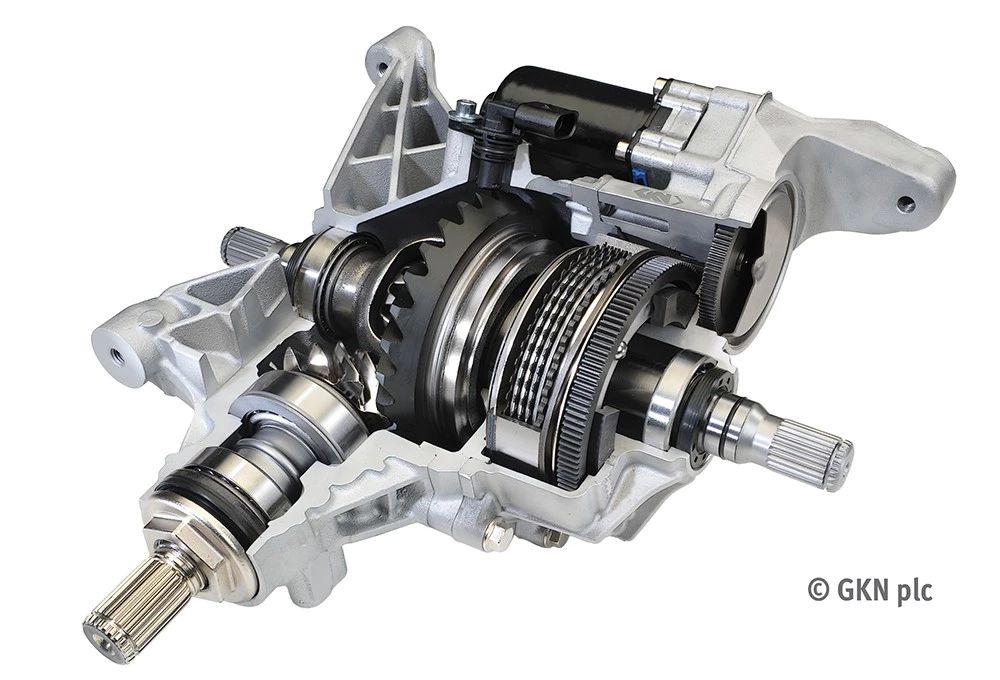

GKN公司研究结果表明,车辆没有必要随时随地为所有车轮提供动力,这会显著降低整个行驶循环的效率。(图片来源:GKN)

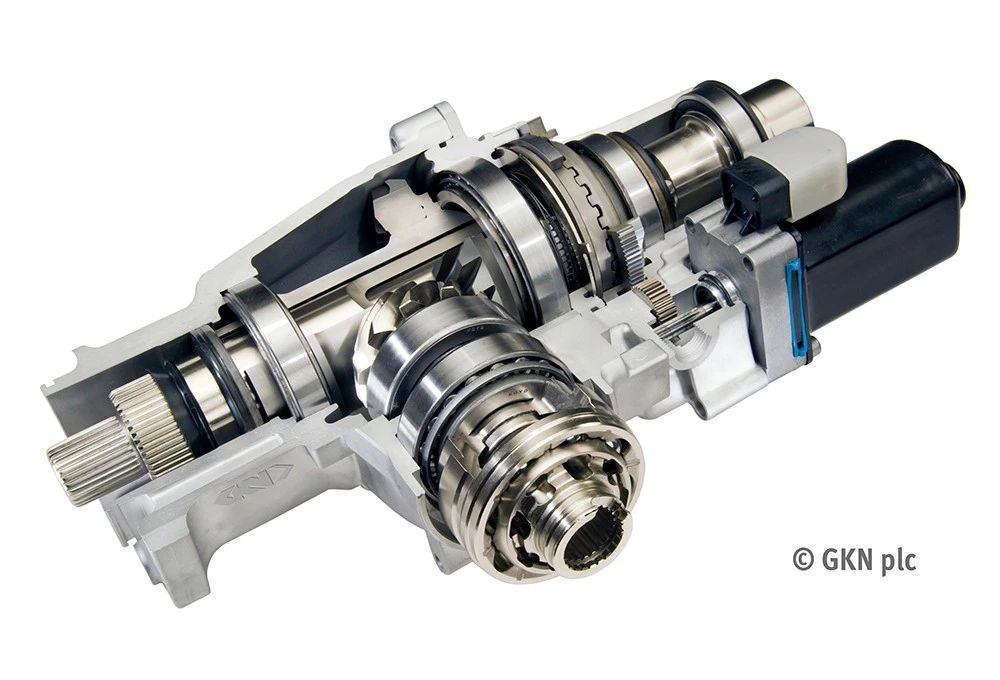

GKN公司研究结果表明,车辆没有必要随时随地为所有车轮提供动力,这会显著降低整个行驶循环的效率。(图片来源:GKN) GKN的单离合器后驱模块和电子扭矩管理器。(图片来源:GKN)

GKN的单离合器后驱模块和电子扭矩管理器。(图片来源:GKN) 这个PTU 动力输出单元是GKN为 AWD 电动汽车设计的单电机解决方案的组成部分。(图片来源:GKN)

这个PTU 动力输出单元是GKN为 AWD 电动汽车设计的单电机解决方案的组成部分。(图片来源:GKN)

乍眼一看,双电机AWD 电动汽车似乎可以满足一些OEM的要求,但 GKN Automotive (吉凯恩汽车公司)最新研究结果表明:要向双电机 AWD 电动汽车说 No!

单电机比双电机设计更适合AWD 电动汽车。近日,GKN Automotive(吉凯恩汽车公司)从事实、数据和成本三个主要方面,深入对比单电机AWD 和双电机 AWD 电动汽车设计后得出结论:“最初应用于内燃机动力汽车的断开技术同样适用于下一代电动汽车。” GKN公司 AWD 系统经理 Michael Höck 表示,“我们在公司位于德国罗马尔的技术中心进行了模拟实验。结果显示,向车辆所有车轮传递动力的最有效方式是使用传统AWD 系统配合断开技术的设计。”

尽管大多数装配AWD 系统的电动汽车和混合动力汽车是通过第二轴的电气化向车轮提供动力,也就是在车辆前方或后方配备一个“悬挂式”电机,作为车辆一级电机的补充。由于这种设计不仅需要两个电机,而且还需要配备两套逆变器和变速器,因此成本相当昂贵。“额外的逆变器和变速器还会耗能,因此车辆的效率就会降低,”Höck 表示,“而效率降低就意味着续航里程缩水,这在电动汽车行业众所周知。”此外,双电机配置的安全性和牵引力在车辆行驶循环的大部分时间中也没有优势。

随着消费者对AWD 电动汽车的需求越来越多,GKN决心详细研究对比各种 AWD 配置的优劣势。GKN的模拟基于“大多数双电机电动汽车基本上一直运行在AWD 模式下”的事实。Höck解释道,“一些系统允许车辆在不需要AWD 功能时断开其中一个电机,从而提高效率。但事实上,系统断开的只有电机耦合部分,车辆传动系统的其余部分仍在运转。”

“这不仅会造成不可避免的寄生损耗,而且根本无法让两部电机的传动比同时调试至最优,”Höck补充道,齿轮传动只能针对单电机或双电机优化,但 AWD 车辆会在两轮和四轮驱动间来回切换,因此无法总是优化至可以提供最高效率的状态。Höck 表示,“机械AWD 系统的优势在于无需在单电机和双电机之间做出妥协。”

GKN在研究之初,选择了一辆带有“悬挂式” AWD 系统的车辆进行模拟,以确定该“悬挂式”系统的工作频率。“测试表明,即使在结冰和雨雪等低抓地力路面条件下,AWD 系统的使用频率也仅有四分之一,” GKN公司 AWD 系统测试协调员 Christoph Schmahl 指出,“在高抓地力的城市和农村路面条件下中,这个数字在 9% 到14% 之间,而在主干道上,AWD 系统的使用频率仅为 1%。研究结果表明,车辆根本没有必要随时随地为所有车轮提供动力,这会显著降低整个行驶循环的效率。”

更简洁、更经济

对比看来,在电动汽车中应用传统AWD 架构似乎更简洁、更高效,而且成本也更低。这种基于单电机的机械AWD 架构仅通过一个动力输出单元(PTU)传动轴和一个后驱单元(RDU)即可为车辆的四个车轮提供动力。

Höck 暗示,AWD 电动汽车提高能效的关键在于离合器,这个离合器必须能在车辆不需要AWD 功能时断开 PTU、传动轴和 RDU。只有这样,电动汽车才能获得大幅的能效优化,并同时提供AWD 车型特有的稳定性和安全优势。此外,传统机械 AWD 设计无需配备第二套电机、逆变器和变速器,因此整体重量更轻,这也可以进一步提高车辆能效。

GKN的ActiveConnect 主动连接系统采用了搭配爪式离合器的 PTU 单元,可在输入轴处断开电机。GKN还在车尾处配备了两个模块化 RDU 单元,从而更好地满足不同应用场景的需求。RDU 助推器则采用了一个侧装式离合器,从而延续传统AWD 系统紧凑、轻质的优势。

GKN 的 Twinster RDU 单元使用双盘离合器取代了传统的差速器,从而进一步增强了车辆的行驶动力学性能。“通过在传动轴的纵向方向对两个后轮应用扭矩控制,车辆在公路和越野路况下的牵引力都得到了提高。”Höck 解释道,“两个系统的断开功能没有差别,因此效率可以得到最大保证,这对电动汽车来说是至关重要的。”

Höck 表示,公司的 ActiveConnect 系统自2014 年登陆传统内燃机车型以来,已经展示了“显著”的节油表现。那么,ActiveConnect系统是否适用于电动汽车呢?事实上,这种“传统” AWD 系统在控制电机初始扭矩方面可以发挥很大作用,并且可以在相对低速下断开,从而在正常驾驶条件下获得最大的能效提升。

单电机解决方案

通过使用基于单电机的ActiveConnect 系统,车辆几乎可以立即将扭矩分配到任何有需要的地方。“例如,在越野路况下,由于前轮的牵引力更高,则系统可以将全部扭矩输送给前轮,”Höck 解释道,“双电机设计却只能将其中一个电机的总扭矩输送给前轴。此外,有了Twinster 的助攻,ActiveConnect 系统还可以优化两个后轮间的牵引力分配。”

ActiveConnect 系统一旦检测到牵引力丢失,可以再次“几乎立即”将高达 100% 的扭矩传递到车辆后方,以更大的牵引力向后轮输送扭矩。此外,如果车辆在弯道行驶中失去牵引力,系统还可以在两个车轮之间重新分配扭矩,从而协助校正偏航力矩。

在测试过程中,ActiveConnect系统的电动汽车模拟结果显示,单电机设计的效率比双电机永久AWD 系统高 9%,比配备电子断开功能的双电机设计高6%。另外需要说明的是,为了模拟最常见的正常驾驶环境,GKN在模拟中采用了 WLTC 全球统一轻型汽车测试循环工况和低断开速度的设置。

Höck 总结了公司有关双电机技术的主要发现:“与配备断开装置的双电机设计相比,带有断开装置的单电机AWD 设计所需的传动系统元件数量大大降低,可以为厂商节省大量成本。由于无需装配第二套电机和逆变器,单电机设计仅在传动系统上就可以节省高达13% 的成本。”

Höck 补充说,未来,某些电动汽车应用也可能都会使用多速电子变速器,而一辆装配单电机 AWD ActiveConnect 系统的电动汽车可以“轻松”集成这一功能,从而通过降低能耗或提高性能来进一步延长电动汽车续航里程。

Two-motor AWD EVs may meet some OEM criteria, but results from GKN Automotive’s new study suggest the temptation should be resisted.

One electric motor for AWD EVs is better than two. That’s the conclusion reached by GKN Automotive after carrying out extensive research into facts, figures and costs of both. “The benefits of disconnect technology initially introduced for use in ICE powered vehicles are just as relevant in the next generation of EVs,” said Michael Höck, GKN Automotive’s manager of AWD systems. “Simulations conducted at our Technical Center in Lohmar, Germany, show that the most efficient way of transmitting power to all wheels is to use a conventional AWD system with disconnect.”

Although most AWD equipped EVs and HEVs send power to the wheels via the electrification of the second axle – with a “hang-on” electric motor that supplements a primary electric motor at the front or rear – it is an expensive configuration, also demanding two inverters and transmissions. “And it results in reduced efficiency, the extra inverters and transmissions causing power losses,” Höck stated. “As everyone connected to EVs knows, reduced efficiency means reduced range.” Also, the two-motor configuration provided no safety or traction benefits for the majority of the drive cycle.

With increasing numbers of consumers requiring EVs with AWD, GKN decided it needed to carry out a detailed study of options and opportunities. Simulations focused particularly on the fact that most dual-motor EV systems run permanently in AWD. “Some systems allow one of the two motors to disconnect when AWD is not required, thereby providing some efficiency gain, but this is purely at the motor coupling; the rest of the driveline still runs,” Höck explained.

“Not only does this create inevitable parasitic losses, it also makes it impossible to optimize gear ratios for both motors,” he added. Gearing is either optimized for a single motor or dual motors but cannot be tuned to deliver maximum efficiency as the drivetrain switches between two-wheel drive and AWD. “The benefit of a mechanical AWD system is that no compromise is required,” Höck said.

GKN’s study commenced with research simulating a vehicle with a “hang-on” AWD system to determine how often it would be needed. “The tests show that even in low-grip conditions such as ice and snow, the AWD system is only required 25% of the time,” noted Christoph Schmahl, GKN’s AWD systems test coordinator. “In high grip urban and rural driving this figure varies between 9% and 14%, while on the main highway, it drops to 1%. The findings indicate that powering all wheels at all times is unnecessary, and significantly decreases overall drive cycle efficiency.”

Simpler, lower cost

A simpler, lower-cost and more-efficient strategy for automakers to deliver AWD in an EV is one which appears, initially, more traditional. Employ a single electric motor with a mechanical AWD layout including a Power Take-off Unit (PTU) propeller shaft, and a Rear Drive Unit (RDU) to transmit power to all four wheels.

The key to efficiency gains for AWD EVs, Höck suggests, is the application of clutches capable of disconnecting the PTU, the propshaft and the RDU in instances where AWD is not required. The significant efficiency optimization that is so critical for EVs is then achievable, while still providing the stability and safety of AWD when needed. Compound this with the weight saved from not requiring a second motor or inverter, and further efficiency gains are also achieved.

GKN’s “ActiveConnect” system utilizes a PTU with a dog clutch allowing it to disconnect at the input shaft. At the rear, depending on the application and the level of sophistication required, GKN offers two modular RDUs designed for ease of integration. The Booster RDU has a single, side-mounted clutch to provide the benefits of a conventional AWD system in a more compact, lightweight package.

GKN’s “Twinster” RDU replaces a conventional differential with twin disc clutches to enhance driving dynamics yet further “With torque control to both rear wheels, and longitudinally along the propshaft, traction is improved both on and off road,” Höck explained. “Both systems incorporate an identical disconnect capability, and therefore the efficiency gains so crucial to EVs.”

Höck said that ActiveConnect had been used in conventional ICE vehicles since 2014, enabling “significant” fuel savings to be made. In terms of suitability for EV applications, this “conventional” AWD system would make a substantial impact in controlling the initial torque of the electric motor, and could be disconnected at relatively low speeds, allowing for maximum efficiency gains under normal driving conditions.

Single-motor solutions

With a single motor ActiveConnect system, torque could be distributed almost instantly to where it was needed. “For example, during off-road driving the system can deliver all of the torque to the front wheels if they have better traction," Höck explained. "A dual-motor setup can only ever transmit to one axle the total torque of one of the two motors. Equipped with Twinster, the ActiveConnect system also allows optimized traction between the rear wheels.”

If the system detected a loss of traction, it could, again, “almost instantly” transmit up to 100% of the torque being transferred to the rear, delivering it to the wheel with greater traction. And torque can be distributed to help correct a yaw moment if the vehicle loses traction mid-corner.

During the test program, ActiveConnect simulations within an EV driveline demonstrated the system to be 9% more efficient than a dual-motor permanent AWD system. And it was also 6% more efficient than a dual-motor setup with an e-motor disconnect function. Simulations were performed using the WLTC (Worldwide Harmonized Light Duty Test Cycle) and a low disconnect speed, indicative of normal driving conditions.

Höck summed up the test findings and the tempting technology of two motors: “A single-motor AWD setup with disconnect also provides a large cost saving to OEMs when compared to a dual-motor disconnect, greatly reducing the number of drivetrain components required. Without a second motor and inverter, and additional gears, a cost saving of up to 13% can be made in driveline componentry alone.”

Höck added that in the future, certain EV applications might also warrant the use of multi-speed e-transmissions, and that an EV with a single-motor AWD ActiveConnect system could “easily” integrate this, increasing its potential range by decreasing energy consumption, or boosting its performance.

Author: Stuart Birch

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分