搭载下一代混合动力系统的斯巴鲁Crosstrek原型车。(丰田)

搭载下一代混合动力系统的斯巴鲁Crosstrek原型车。(丰田) 从左至右,斯巴鲁总裁兼首席执行官 大崎敦司、斯巴鲁高级常务执行官兼首席技术官 官藤贯哲、丰田总裁兼首席执行官 佐藤恒治、丰田执行副总裁兼首席技术官 中岛裕树、马自达总裁兼首席执行官 毛笼胜弘、马自达高级常务执行官兼首席技术官 广濑一郎。(丰田)

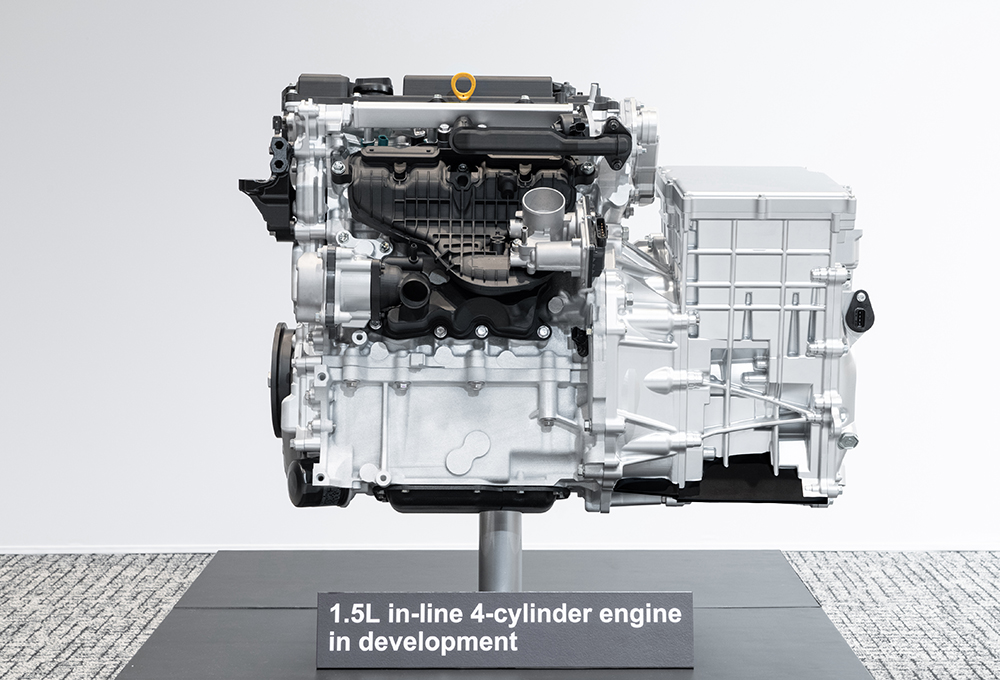

从左至右,斯巴鲁总裁兼首席执行官 大崎敦司、斯巴鲁高级常务执行官兼首席技术官 官藤贯哲、丰田总裁兼首席执行官 佐藤恒治、丰田执行副总裁兼首席技术官 中岛裕树、马自达总裁兼首席执行官 毛笼胜弘、马自达高级常务执行官兼首席技术官 广濑一郎。(丰田) 丰田汽车正在开发的1.5L直列四缸发动机。(丰田)

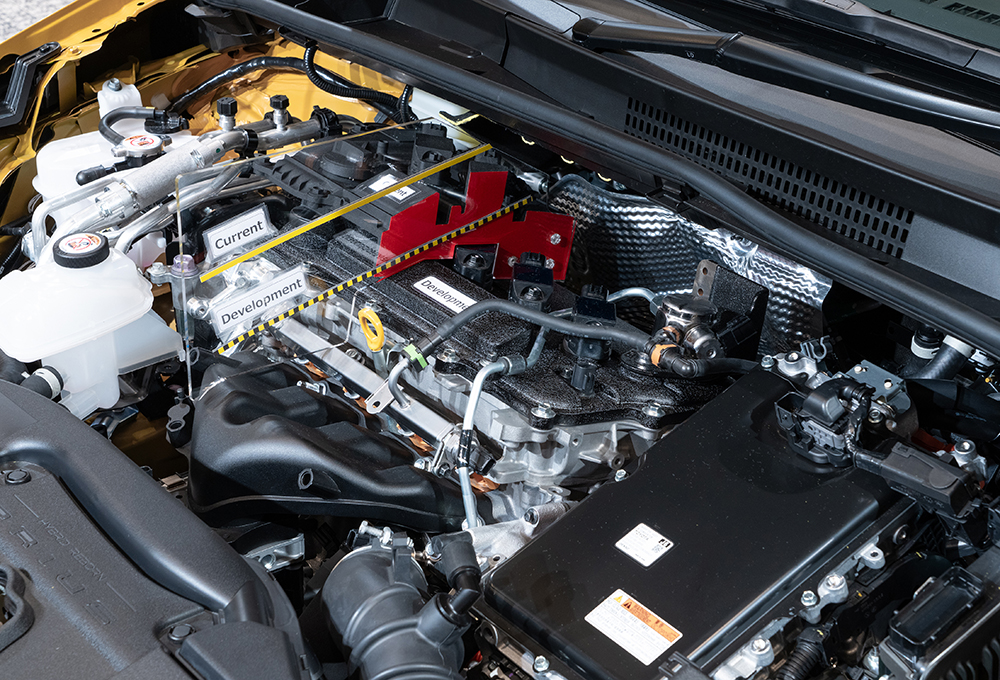

丰田汽车正在开发的1.5L直列四缸发动机。(丰田) 丰田汽车正在开发的装有1.5L直列四缸发动机的样车。(丰田)

丰田汽车正在开发的装有1.5L直列四缸发动机的样车。(丰田) 斯巴鲁新一代混动系统。(斯巴鲁)

斯巴鲁新一代混动系统。(斯巴鲁)

这三家日本汽车制造商表明未来将提供更多类型的内燃机。

丰田、马自达和斯巴鲁在联合发布会上表示,未来将致力于研发新型内燃机技术并探索其在电气化时代的应用方式,特别是在混合动力汽车和插电式混合动力汽车中的应用。此外,它们还鼓励增加生物燃料和合成燃料等石油替代燃料的使用,以助力实现汽车碳中和的目标。这三家OEM在联合声明中强调,它们将推动新型高效内燃机的研发,并将重点放在脱碳方面,从而使内燃机与电机、电池和其他电驱部件能够更好地结合使用。同时,他们也明确表示不会排除仅开发电动车的计划。

佐藤表示,“基于将发动机与电动部件相结合的理念,我们将充分利用电机和发动机各自的优势领域来改进现有技术,以提升效率。此外,我们还将根据电气化需求优化发动机的结构,使其变得更紧凑、安装更灵活,从而更具竞争力。

丰田首席技术官中岛裕树表示,丰田新型1.5L自然吸气发动机的体积和高度将比现有版本减少10%,同时燃油经济性更为出色,输出功率大致相同。新型1.5L涡轮增压新型发动机的体积将比现有2.5L自然吸气发动机减少20%,高度减少15%,尽管其燃油效率略低,但输出功率会提高30%。此外,丰田新型2.0L发动机的体积和高度都将比现有2.4L涡轮增压发动机减少10%,效率更高,输出功率也会提高30%。

他表示,“我们相信,转子发动机很有可能在电气化时代提供新的价值。目前,我们正在全力攻克转子发动机面临的排放合规性问题。”

大崎敦司指出,斯巴鲁未来的混合动力汽车和插电式混合动力汽车可能配备与油车尺寸相同的油箱,但不一定使用化石燃料。“斯巴鲁也希望能与其他公司携手推动碳中和目标的实现”,“要应对建设碳中和的挑战,我们三家公司的努力是远远不够的,需要日本汽车行业和整个社会的共同努力。”

斯巴鲁称,将于2024年秋季开始在其位于日本埼玉县的北本工厂生产用于下一代混合动力系统的变速驱动桥(transaxles)。

Toyota, Mazda and Subaru announced a new technological effort to create new internal combustion engines and ways to use them in the electrification era, specifically for hybrid and plug-in hybrid vehicles. The companies said at a joint press conference in Japan that they would encourage increased use of petroleum alternatives like biofuels and eFuels in their effort to create carbon-neutral vehicles. A joint statement from the three OEMs claims this push for new and better ICEs comes with a focus on “carbon as the enemy” as they develop engines that can better work with electric motors, batteries, and other electric drive units. Toyota, Mazda and Subaru made clear they are not getting rid of EV-only vehicle plans.

Here’s how each company will approach the new ICE+EV era (quotes provided in English by on-site interpreters).

Toyota: smaller, better engines

Toyota will develop new, low-displacement inline four-cylinder engines, Toyota president and CEO Koji Sato said, with an emphasis on increased efficiency and more compactness by combining the engine with an electric power unit.

“Based on the concept of adding an engine onto an electric unit, we are refining our technology to achieve higher efficiency than before by leveraging the areas in which each electric motor and engine excel,” Sato said. “By optimizing engines for electrification, we will make their structure more competitive and compact, which will lead to more flexibility in engine installations in cars.”

Toyota’s chief technology officer, Hiroki Nakajima, said that the company’s new, naturally aspirated 1.5-L engine would be 10% smaller in both volume and height, while offering better fuel economy and around the same power output. The new 1.5-L turbo engine would be similarly smaller (a 20% volume reduction and a 15% height reduction) compared to the current 2.5-naturally aspirated engine and will trade slightly worst fuel-efficiency for a 30% improvement in horsepower. Finally, Toyota’s new 2.0-L engine will, compared to the current 2.4-L turbo, be 10% smaller and shorter, with better efficiency and, again, around 30% higher hp.

Mazda: rotary to the future

Mazda is looking to the past when it comes to finding the correct future for ICEs by considering using the rotary engine for the new HEVs and PHEVs.

“From an early stage, we have explored the environmentally friendly potential of these engines, including burning hydrogen in the 1990s,” Mazda president and CEO Masahiro Moro said during the press conference. “Rotary engines are compact and lightweight, and yet have a high output. The structural characteristics make them omnivores with respect to fuels. What's more, though not widely known, their compact size and relative freedom in the layout of auxiliary parts allow for high space efficiency and easy mounting of electric devices, offering a great advantage for innovative packaging and design.”

Moro said the inherent benefits of a rotary engine, specifically the quietness and low vibration, give it a "singular value.”

"We believe that the rotary engine holds great potential for providing new value in the age of electrification and we are devoting all our energies to overcoming the current challenge of emission compliance for our rotary engines,” he said.

Subaru: EVs with AWD will keep the “Subaru difference”

Subaru is not giving up on the Boxer engine. New ICE-plus-electric powertrains from the company will keep the brand’s symmetrical all-wheel drive layout for future hybrid and PHEV models, but Subaru president and CEO Atsushi Osaki said his company remains open to all different kinds of powertrain options.

“At Subaru, we are navigating this period of a great transformation by focusing on flexibility and expandability,” he said. “At Subaru, internal combustion engines mean horizontally opposed engines. The company's pioneers regard longitudinally mounted, horizontally opposed engines as the logical and ideal source of power for automobiles. This has developed into Subaru’s unique symmetrical AWD system with a superior packaging that takes advantage of a symmetrical powertrain layout and the features of a horizontally opposed engine: lightweight, compact, low center with gravity reduced vibration and the safety in collisions.”

Subaru’s new powertrain layout, still with AWD, will be a series-parallel system that uses an ICE that will either directly power the wheels or send power to a generator, which will in turn power a batter that moves the motor and then the wheels. The car will decide where to send ICE energy by choosing the most-efficient path.

Subaru’s future hybrid and PHEV models will likely have fuel tanks that are the same size as a gasoline-only car, Subaru said, but it won’t need to be filled with a petroleum product. “Subaru is also eager to collaborate in efforts to promote the adoption of a carbon neutral,” Osaki said. "The challenge of creating a carbon neutral society needs to be tackled and not just by the three companies here, but by all of the Japanese industry and society.”

Subaru said it will start producing transaxles for the next-generation hybrid system in the fall of 2024 at its Kitamoto Plant in Saitama Prefecture, Japan.

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分