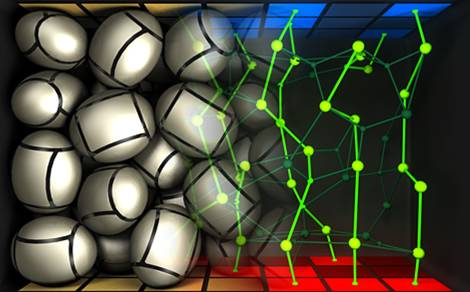

Tanktwo串电池使用带有多压力触点的“智能”电芯替代“普通”电芯。上图所示的电芯具有6个外部触点。

Tanktwo串电池使用带有多压力触点的“智能”电芯替代“普通”电芯。上图所示的电芯具有6个外部触点。 串电池可以在没有人工干预的情况下,自动“串联”形成串电池。电池中的串联算法可以持续监测网络情况,并在有必要时创造新的连接。

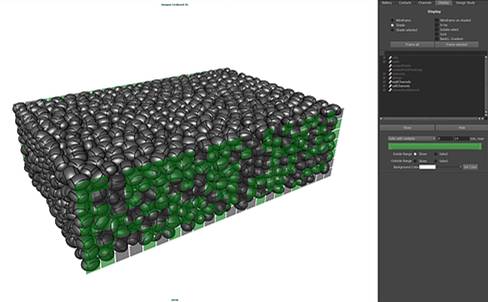

串电池可以在没有人工干预的情况下,自动“串联”形成串电池。电池中的串联算法可以持续监测网络情况,并在有必要时创造新的连接。 图为串电池的仿真图。由硅树脂材料制成的充气气囊可以在车辆移动时保证电芯不会随意移动。Tanktwo公司声称,对于拥有6个触点的电芯而言,电池组完全可以取得98%以上的利用率,接触点退化及可能的腐蚀问题也可以通过很多方法解决。

图为串电池的仿真图。由硅树脂材料制成的充气气囊可以在车辆移动时保证电芯不会随意移动。Tanktwo公司声称,对于拥有6个触点的电芯而言,电池组完全可以取得98%以上的利用率,接触点退化及可能的腐蚀问题也可以通过很多方法解决。

看起来,电力推进系统似乎注定将在未来取代内燃机,但现阶段而言,电动车电池仍然很贵,电池组还是很重,而且充电时间也仍然也比汽车加油慢的多。尽管存在众多优势,但电动车的这些弱点也同样不容忽视。因此,从经济和市场规律来看,内燃机很可能并不会在未来几十年内“谢幕”。

不过,现在来了解一下Tanktwo公司及一种真正创新的电动车电池吧。

现阶段电动车电池架构的基础是一种名为“电芯”的组件。这些电芯通常采用圆柱 或矩形设计,已经在消费电子领域有大量应用,因此对电动车电池厂商很有吸引力。这些电芯可以首先组成电池模块,而电池模块经过设计组合后又可以组成固态电池组。

Tanktwo计划打造一种由“蛋型”电芯组成的电池组。这家芬兰公司的创始人利用自身在远程通信领域的背景,打造了一款内置小型编程计算机的“智能”电芯。他们可以直接将这些电芯“倒入”一个内部具有触点的平价容器内,形成公司所称的“串电池(String Battery)”。

常规电池尺寸太大

目前,Tanktwo已经在美国纽约开设了办公室,公司CEO Bert Holtappels表示,“串电池”最大的优势也正是传统电池概念的劣势所在:电池容量从设计之初就已经严格确定,不能更改了。

“这样的电池系统效率很低,为了将故障率控制在可以接受的范围内,传统电池的尺寸通常都有较大富余。”Holtappels解释说,现在很多厂商的电动车电池组容量高达100 kW·h,而车主通常每年也只开20,000公里,这意味着“这些电池的折旧很大程度上来源于自然老化,而不是真正使用。”这是一种很大的资产损失。

对比来看,在使用Tanktwo的串电池时,用户只需向电池容器中“倒入”所需数量的电芯,外加少量额外的备用电芯即可。而后电池组的外容器可以通过SAE J1772标准插头为电芯充电。“这可以保证电池得到充分利用,”Holtappels解释道,“这样一来,在购买电动车后,车主就可以随时到经销商处轻松升级自己的电池组。”

商店里的吸尘器算的上是形式最简单的换电设备。Holtappels承认,我们必须改变电池结构,才能实现便捷快速的电池更换,氢燃料电池就是一个例子。他推测说,“未来,这可能会自然而然地成为现实。”

新设计,高效率

“串电池”还有从其他方面提高电池效率的潜力。当下的电池组设计需要平衡同个模块内所有电芯的电量水平。因此,我们假设有一个电芯有20%的损坏,那这个模块中的剩余电芯也必须放掉20%的电量,从而保证整体的平衡。这样一来,只要一个电芯出了问题,整个电池模块的功能都会受到影响。

也正是这个原因,传统电池通常需要设计更大的富余。这意味着如果一款电池希望在整个生命周期内均保持8 kW·h以上的容量,那该电池一开始最少需要设计14或16 kW·h的容量。

对比来看,由于“串电池”很智能,因此电池组的能效并不会受到“状况最差”的那个电芯的限制。根据Holtappels的描述,如果单个电芯坏了20%,那电池组供电时仅会绕过这20%的损坏电芯,并不会产生其他影响。每个电芯均尽最大能力为电池组供电,即使有所损坏也不会“拖累”其他电芯放电以保持平衡。

Holtappels估算,与额定功率相同的传统电池组设计相比,Tanktwo串电池的效率高10%。

“从实用角度看,我们电池的使用寿命要长的多。”Holtappels表示,“大多数公司的共识是,当电池组的可用部分还剩70%时,就该更换电池了,但只要剩余容量仍在10%以上,我们的串电池就完全可以继续工作”

Tanktwo公司表示,完全或部分损坏的电芯对传统电池有致命打击,但串电池则可以绕过这部分故障电芯继续工作,而且用户还可以在服务站内轻松换掉这部分电芯。因此,串电池的电池组尺寸是按正常使用情景,而非最坏情况设计的。此外,串电池组用来装电芯的容器相当简单,类似总线等重要组成部分也采用了商品化的设计。由于自身特点,串电池对电池容器的形状并没有要求。

Holtappels表示,“这项技术不受电池化学种类的限制,电池化学领域的进步也会同时提升串电池的性能。”

Holtappels表示,目前,Tanktwo已经找到了多个行业伙伴,共同进行串电池的初步研发,其中包括提供电动服务汽车的Firefly公司。对于这部分用户而言,能否进行快速电池替换(Tanktwo称“3分钟”)至关重要。

Total Battery Consulting公司的Menahem Anderman博士认为,“这绝对算的上一个开创性思路,但似乎相当具有挑战性。”在接受本文作者的采访时,Anderman博士表示,希望未来这种“动态”电池结构能够经受考验,真正在系统复杂度、成本和可靠性等方面达到平衡。

Anderman博士表示,“我相信,这种电池概念转为真正电池系统还需要相当长的时间。”毫无疑问,Tanktwo公司也意识到自己面临的挑战。未来有关串电池的更多信息,敬请关注。

While electric propulsion appears destined to supplant the internal combustion engine at some point in the future, the laws of economics and market forces will likely keep ICEs around for decades. Batteries for EVs remain expensive. Packs are heavy, and recharging takes longer than pumping liquid fuel into a tank. Despite their many advantages, EV disadvantages are hard to ignore.

Enter Tanktwo and a truly novel approach to the basics of EV batteries.

The basis of EV batteries today starts with a small component collectively known as a cell. Typical cells are shaped as cylinders or rectangular slabs. What makes them attractive to electrified vehicle battery makers is they are widely used in consumer electronics. Cells are combined into modules, modules into a highly engineered, static battery pack.

Tanktwo’s vision is a battery pack composed of egg-shaped String Cells. The Finland-based company’s founders exploited their background in telecommunications to create 'smart' cells that contain small, programmed computers. Poured (literally) into an inexpensive passive container with contacts on the inside, they create a String Battery.

Conventional batteries too big

One of the biggest benefits of the String Battery lies in a problem with current battery concepts—capacity rigidly designed from the outset, according to Bert Holtappels CEO of Tanktwo which has an office in New York.

“These systems are inefficient because they need to be over dimensioned with significant margin, so that the likelihood of field failure is within an acceptable margin,” he said. Some EV makers are delivering cars with 100 kW·h battery packs when their owners might drive only 12,000 mi (19,311 km) per year, meaning that "most of the depreciation of the battery is coming from aging, not wear”—a costly loss of an asset, Holtappels explained.

Sizing the Tanktwo String Battery container for the maximum scenario requires filling only as many cells as needed for a typical usage, plus a healthy margin. The container would recharge the cells through the normal SAE J1772 plug as today. “This prevents underutilization of the pack,” he explained. “During the period he owns the vehicle, the same customer could visit the dealer and get an upgrade to the battery pack quite easily.”

The simplest version of the swapping device resembles a glorified Shop Vac. Holtappels recognizes that the more ambitious goal of convenient and fast battery swapping requires an infrastructure change that could inhibit adoption—think hydrogen fuel cell vehicles. “That might come naturally over time,” he speculated.

Efficient by design

There are some other potential efficiencies of the String Cell approach. Current battery packs need to level the charge between cells in each module. So, if one cell has deteriorated by, say 20%, the rest of the cells in the module must bleed off energy to balance the cells within the module. So, each module is limited by the deterioration of any individual cell.

This also causes traditional packs to need large safety margins. Often, this means a battery designed to maintain an 8 kW·h capacity over the life of the car might start out with 14 or 16 kW·h.

Because String Cells are ‘smart’, the pack is not limited by the least-charged cell. As Holtappels describes it, if an individual cell deteriorates by 20%, the cell is simply bypassed for 20% of the time when the pack is contributing power. Each cell contributes to the pack to the best of its ability without any need to bleed off charge.

He estimates this as providing 10% more energy efficiency when compared to traditional pack designs with the same rated energy.

“Our packs can last much longer on a practical level as well," Holtappels claimed. "Most companies [think they should retire their] pack from the vehicle even when it is still 70% usable. For String Cells, anything over 10% of initial capacity is OK for each cell.”

Dead or semi-dead cells that would be ruinous in a traditional pack can be bypassed in a String Battery, and easily replaced at a service or swap event, the company claims. So the packs are sized for the mean, not the worst case. The containers they go into are also fairly simple. Important components, such as bus communications and wire harnesses are already commoditized. Because of the unique character of the String Cells, there is flexibility in the shape of the container.

“This technique is agnostic about the battery cell chemistry: any improvement in the chemistry of cells would also improve the String Battery,” he said.

According to Holtappels, a couple of industry partners are already working with Tanktwo on initial deployments, including Firefly with an electric service vehicle. In these cases, the rapid battery replacement—3 minutes according to the company—was an important factor.

"This is definitely an out of the box idea, but it seems quite challenging," observed Dr. Menahem Anderman of Total Battery Consulting‘. Interviewed by the author for this article, Dr. Anderman would like to see future trials prove out the quality of the 'dynamic' electrical contacts between the cells, and examine complexity, cost and reliability in real life.

"I believe it will be quite a stretch to make a real viable system out of the concept," he said. There is no doubt the Tanktwo principals are just as aware of the challenges. Stay tuned.

Author: Bruce Morey

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分