伊顿四速手自一体变速箱专为电动车设计。(SAE/Matt Wolfe)

伊顿四速手自一体变速箱专为电动车设计。(SAE/Matt Wolfe) 伊顿、BAE的测试卡车虽然尚未投入生产,但与许多原型车相比,看起来更接近于可上路的产品。(SAE/Matt Wolfe)

伊顿、BAE的测试卡车虽然尚未投入生产,但与许多原型车相比,看起来更接近于可上路的产品。(SAE/Matt Wolfe) 伊顿电动动力总成产品总监Justin Hopkins说:“通过引入变速箱,可以减轻整体重量,降低整体电机成本。”(SAE/Matt Wolfe)

伊顿电动动力总成产品总监Justin Hopkins说:“通过引入变速箱,可以减轻整体重量,降低整体电机成本。”(SAE/Matt Wolfe) 伊顿变速器和BAE系统的测试平台是一辆Freightliner M2。(SAE/Matt Wolfe)

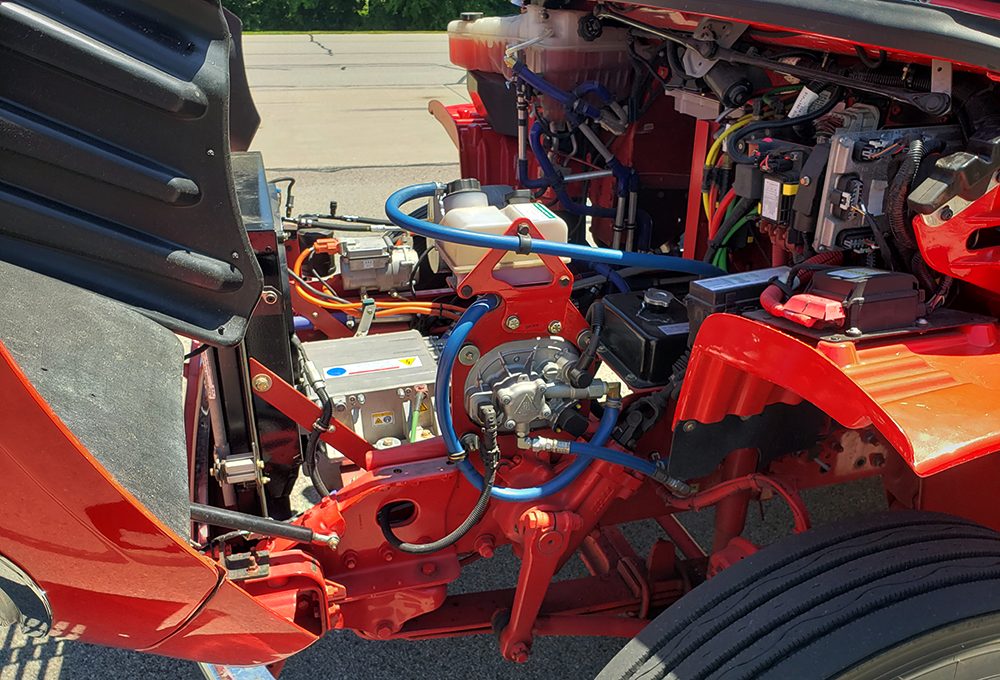

伊顿变速器和BAE系统的测试平台是一辆Freightliner M2。(SAE/Matt Wolfe) 伊顿和BAE测试卡车“引擎”盖下的一瞥。(SAE/Matt Wolfe)

伊顿和BAE测试卡车“引擎”盖下的一瞥。(SAE/Matt Wolfe) 伊顿和BAE测试卡车“引擎”盖下的一瞥。(SAE/Matt Wolfe)

伊顿和BAE测试卡车“引擎”盖下的一瞥。(SAE/Matt Wolfe) 伊顿和BAE测试卡车“引擎”盖下的一瞥。(SAE/Matt Wolfe)

伊顿和BAE测试卡车“引擎”盖下的一瞥。(SAE/Matt Wolfe)

伊顿和BAE系统公司(BAE Systems)合作研发了一款配备BAE电子组件和伊顿四速变速箱的电动动力总成。

长期以来,OEM一直大力宣传纯电动车无需使用变速箱等部件,因为电机提供了足够的瞬时扭矩,不再需要使用其他设备在选定减速比的基础上提供更多的扭矩增益。然而,汽车行业发现这一概念在特定的应用场景中存在局限性。

在连续坡道或高速公路上运载重物时,纯电动车的直驱电机的效率和续航里程可能会迅速降低。虽然可以通过增加电池和电机尺寸来提升负载能力,但这会增加车辆的成本和重量,导致问题变得更加严重。

为解决这一问题,伊顿和BAE系统公司共同研发了一种解决方案,该方案不仅为纯电动卡车提供了更大的灵活性,还可以使用尺寸较小电池组和电机,并同时实现与同等燃油卡车相当的性能。

“根据经验,市场最终都将趋于整合和简化。目前卡车行业引入了大量新技术,许多OEM都竞相推出产品以抢占市场,这些产品往往包含大量模块、线缆和连接件的高度零散的架构。虽然这一做法确实令产品实现了电气化,但可能并不是最佳的解决方案。”

Webb总结,“许多部件都可能出现故障,不仅会增加成本和复杂性,还会增加制造难度。我们尽可能集成和应用多种先进的商业化材料技术,以提高产品散热性能和工作效率,从而简化产品的制造、安装和服务过程。”

“电机效率图上的峰值效率区间比内燃机的最佳效率点宽广得多。但我们还是需要优化电机的峰值效率,以实现最大续航里程。因此,如果要同时满足这两方面的要求,变速箱就会非常有用。”

伊顿集成到测试卡车上的变速箱只有四个档位,这比常见内燃机卡车和轻型车辆的档位数量要少得多。Hopkins解释道,“因为电机的运行范围比发动机广得多,因此无需那么多档位。总之,我们已经找到了满足市场需求的最佳解决方案。”

伊顿变速箱的测试平台是用2018款Freightliner(福莱纳)M2双排座驾驶室改装的,并配备了一个齿轮比为3.9:1的Meritor(美驰)后桥。虽然这辆测试车最初使用液体燃料(而非电力)作为动力,但其动力总成的整体改装和集成过程却非常简单。

Webb指出,“你可能发现,各种展会上展示的许多第一代电动卡车都有大量部件。这些卡车通常采用高度零散的架构,因此如果将化石燃料换成电力,就需要为所有这些部件供电。因此,我们构建了一个集成多种功能的六合一架构。”

Webb继续说,“这样一来,一个核心模块就可以服务于多个市场,这不仅提升了所有核心功能的通用性,还降低了非重复性工程成本(NRE),从而使OEM和最终用户都能受益。考虑到平台电气化成本高昂,通用性核心功能将惠及整个行业。”

在伊顿试验场特意建造的土路上进行坡道测试时,该卡车也展现出稳定的性能,没有出现尘土飞扬的情况。不过,由于车辆在完全停止的状态下也能将扭矩拉满,因此即使挂在一档上,开足马力仍会令车轮在低摩擦系数路面上打滑。但这辆原型车的电门经过了精心校准,因此后轮打滑不会引起严重的扬尘。

其实在伊顿和BAE系统公司之前,已有公司尝试在纯电动卡车中搭载变速箱。例如,沃尔沃也在其VNR Electric上配备了双速变速箱。然而,伊顿和BAE系统公司的解决方案表明,配备变速箱不仅可以提高电动动力总成的操作灵活性,还能显著简化安装过程和整体架构,同时提供车队运营商所需的必要性能。

One of the advantages that OEMs have long touted for battery-electric vehicles (BEVs) has been the elimination of components like the transmission. The instant torque that an electric motor can supply often mitigates the need for any sort of torque multiplication beyond what the chosen axle ratio can provide. However, what the industry has found is that this concept has its limitations in certain use cases.

When asked to haul heavy loads over sustained grades or at freeway speeds, a direct drive BEV powertrain rapidly begins losing efficiency and range. Of course, batteries and motors can be scaled up to handle heavier loads, but these methods add both cost and weight to vehicles for which these specs are already major concerns.

To that end, Eaton and BAE Systems have teamed up to create a solution that not only provides greater flexibility for battery-electric trucks, but also enables smaller scale battery packs and motors while still matching the performance of an equivalent internal combustion engine (ICE) truck.

SAE Media was invited to a ride-and-drive event demonstrating their collaborative creation, where we experienced their test truck from behind the wheel and learned how all the systems work together to reduce overall complexity.

Gearing up

Eaton is not new to providing transmissions for heavy-duty trucks. The company formed an E-Powertrain division several years ago specifically for developing EV-centric components and systems. “What we do is focus on the mechanical components of an electrified powertrain such as differentials, reduction gears and full transmission systems,” said Justin Hopkins, product director, E-Powertrain, Eaton.

BAE is Eaton’s partner on the electrical side of the powertrain, providing motors, inverters and power electronics. Tom Webb, director of business development and strategy, BAE Systems, outlined where the electrified truck market is in BAE’s view and where the highest adoption rates seem to be among the various sectors of the trucking and commercial vehicle industry.

“In terms of market segments where EVs are actually capturing market share, we’re seeing a lot of transit bus, school bus and materials handling,” Webb said. “That may be due to incentives for the first two, but for the third it’s actually now become economically sustainable. Those are all good duty cycles for BEVs, but for some segments the infrastructure isn’t there yet. Obviously, there’s still a lot of challenges ahead with electrification, and we’re not going to tell you that it’s all ready for primetime. But in some market segments, it’s really getting there.”

“We seek to consolidate and simplify because of experience,” Webb continued. “On the trucking side, a lot of this technology is new with a lot of OEMs rushing to get products to market and tick that box. A lot of them are taking a very distributed approach to the architecture with a lot of boxes, wires and interconnects. It does make the product electrified, but it’s probably not the best way.

“There are too many things that can break, add cost and complexity and are not easy to manufacture. What we’re trying to do is integrate and use as many advanced commercial technologies as possible in terms of materials to get heat out, get efficiency up and ultimately make things easier to manufacture, install and service.”

Hitting the spot

Hopkins detailed why adding a gearbox to an electrified powertrain provides greater flexibility not only in design but also in overall performance. “For transit, most of the buses we see do not travel above 45 mph (72 kph). Now there are buses that do have to drive up steep hills like in San Fransisco,” he said. “But in the truck space, a gearbox helps significantly because you have to be able to do 70 mph (112 kph) and also climb some serious grades. Which is why we realized right away that going to a gearbox would be a big advantage over a direct drive architecture.”

There are other advantages too, such as downsizing the motor and power electronics. “The truck market is not as subsidized, it is more TCO and cost sensitive,” Hopkins said. “Because you need the combination of excellent startability, we have to ask, ‘what is the steepest grade I can start on with a full load?’ You also have to look at cruising efficiency.”

“It’s very difficult to get that out of a direct drive solution because your motor is being asked to do two different things: run at high speed very efficiently or produce a ton of low-end torque,” Hopkins continued. “So, it’s a lot easier once you have multiple speeds to be able to have a standard motor that doesn’t [require] extreme high-end torque and can be more optimized to operate at a more moderate speed in the sweet spot of a motor’s efficiency.”

An electric motor’s efficiency map is “a lot wider and more expansive than an ICE sweet spot in terms of peak efficiency,” Hopkins noted. “But you’re still trying to optimize that motor for peak efficiency where you’re doing the most amount of miles. So, when you get that multiplication for both those demands, it’s very helpful to have the gearbox.”

Hopkins also explained how introducing a transmission can reduce overall cost of an electrified powertrain. “Copper is expensive, and you also have various motor types that use rare earth metals. Scaling these motors up also adds weight. By introducing a transmission, you’re reducing overall weight and reducing overall motor costs,” he said.

The transmission that Eaton has integrated into the test truck has only four speeds, which is a fraction of what has become customary not only in trucks, but also light vehicles. “Because the motor has a much larger range of operation, you don’t need as many speeds,” Hopkins explained. “We really landed on as where we think the market sweet spot is.”

Cutting complexity

The test bed for Eaton’s EV transmission is a reworked 2018 Freightliner M2 crew cab equipped with a Meritor rear axle geared at 3.9:1. While this is still a test mule that began its life running on liquid gold rather than electrons, the overall installation and integration of its adopted powertrain is noticeably simple. It’s what you don’t notice under the hood that catches your eye.

“There’s a lot of current generation-one EV trucks that you see at various tradeshows that have a lot of ‘stuff’ in them. A lot of these generation-one EVs have a very distributed architecture [and] when you remove petroleum, you have to power all your accessories with electrons,” BAE’s Webb said. “So, what we’ve done is build a six-in-one architecture where we’ve integrated a lot of different functions.”

Indeed, the simplicity of the installation makes the test truck in question look much closer to a production-ready product rather than a rolling laboratory. “Our system isn’t just highly integrated, it’s also modular,” Webb said. “So, each of these functions are like slices that can come together or be removed so we can expand and contract them. We wanted to have the ability to support different platforms and duty cycles so that we didn’t constantly have to go back and start from scratch.”

“This allows us to service multiple markets with a core building block,” Webb continued. “That drives commonality between all the core functions, but also benefits the OEM and end user in terms of reducing NRE [non-recurring engineering]. It’s expensive to electrify each platform, so if there’s commonality that carries over, that helps the industry.”

Take a ride

SAE Media was permitted to take Eaton/BAE’s test mule for an extended test drive around Eaton’s proving grounds in Marshall, Michigan. The facility features an oval test track, an off-road course and several paved and unpaved grades ranging from 5- to 25-percent.

As noted by Hopkins, the transmission really does not shift much on level surfaces and below freeway speeds. However, we were able to verify his claim that above 62 mph (100 km/h), the transmission did indeed grab fourth and operate as a direct drive unit would mechanically even with a load in the back.

We also tackled various grades in the truck, which provided an opportunity to show off a few of the truck’s party tricks. The powertrain has a hill hold function that works much like an ICE vehicle would. Even on grades as steep as 25%, one could lift their foot off the accelerator and the truck would hold itself on the grade for a short period before freerolling again.

The steeper grades also provided an opportunity to demonstrate the shift logic of the transmission when more torque is required to make a hill. Like an ICE vehicle, the truck will usually not give a downshift command under full acceleration. However, if the driver feels the truck slowing while on a steep grade, a lift off the accelerator at a low enough speed would signal the transmission to engage first so that the truck could continue climbing.

The off-road grades also demonstrated the truck’s capability to not turn the manicured dirt roads of Eaton’s proving grounds into the starting line of a WRC stage. Naturally, because full torque is available from a dead stop, full power in first gear would likely spin tires in low mu situations. However, the throttle calibration is refined enough even in this prototype that its rear tires won’t suddenly turn into gravel machine guns.

Final thoughts

What Eaton and BAE have collaborated to create is quite impressive. By reintroducing a transmission to a BEV powertrain, they have demonstrated that an electrified powertrain can be even more flexible for truck applications while also reducing the overall weight of the motor and battery packs, which is still a major sticking point for pure electric vehicles.

Eaton and BAE are not the first to put a gearbox in a battery-powered truck. Volvo, for example, uses a two-speed gearbox in its VNR Electric. But their approach demonstrates that not only can electrified powertrains become more flexible in operation, they also can be far more simplified in terms of installation and overall architecture while still providing the necessary performance that fleet owners demand.

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分