2011 年加入天纳克之前,Patel 博士曾在通用电气公司工作了 13 年,担任化学家、资深科学家和技术企业领导者等职位。图为Patel 博士与天纳克的主动悬挂产品。

2011 年加入天纳克之前,Patel 博士曾在通用电气公司工作了 13 年,担任化学家、资深科学家和技术企业领导者等职位。图为Patel 博士与天纳克的主动悬挂产品。 装配的艺术:天纳克为戴姆勒最新 NRM 系列轻型汽车柴油发动机提供了完整的热端后处理套件,其中包括D - ox 催化剂、混合器和采用 SCR 涂层的 DPF 单元。NRM 系列发动机将应用在多款梅赛德斯奔驰汽车中。

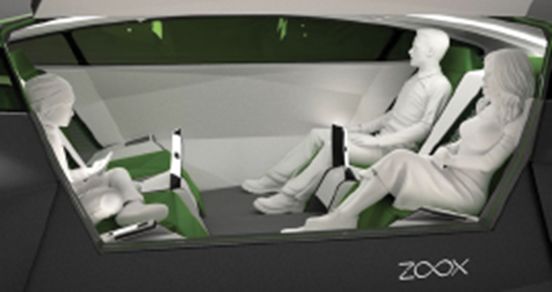

装配的艺术:天纳克为戴姆勒最新 NRM 系列轻型汽车柴油发动机提供了完整的热端后处理套件,其中包括D - ox 催化剂、混合器和采用 SCR 涂层的 DPF 单元。NRM 系列发动机将应用在多款梅赛德斯奔驰汽车中。 天纳克开发的最新悬挂设计和驾乘控制系统有助于缓解自动驾驶汽车乘客的晕车困扰。由于自动驾驶汽车将采用非常具有特色的后向座椅设计,因此晕车问题将更加凸显(图为Zoox 公司的概念设计)。

天纳克开发的最新悬挂设计和驾乘控制系统有助于缓解自动驾驶汽车乘客的晕车困扰。由于自动驾驶汽车将采用非常具有特色的后向座椅设计,因此晕车问题将更加凸显(图为Zoox 公司的概念设计)。 天纳克的声学控制系统允许采用汽缸钝化技术的车辆在切换点火模式时,改变排气“音质”。图为雪佛兰 Corvette 汽车底盘的后半截。

天纳克的声学控制系统允许采用汽缸钝化技术的车辆在切换点火模式时,改变排气“音质”。图为雪佛兰 Corvette 汽车底盘的后半截。 天纳克最新设计的排气系统采用了带有内部控制的热交换技术,专门面向蓬勃发展的混合动力汽车市场。

天纳克最新设计的排气系统采用了带有内部控制的热交换技术,专门面向蓬勃发展的混合动力汽车市场。

通常来说,排气系统总是很难抢到“头条”,哪怕已经配备了一些“酷炫”的先进电子系统。然而,下一代混合动力推进系统的工程师却明白,如果有一套排气系统不但能够收集废热,运行时不会发出刺耳噪声,甚至还能在纯电力低速行驶模式下发出声音提示行人,从而保证行人的人身安全,那这套排气系统绝对是一项值得考虑的技术资产投资。

事实上,这正是我最近在天纳克 53 英尺的演示拖车中的想法。在面前的桌子上,我可以看到一套采用TIG 焊接工艺的排气系统,设计干脆整洁性,同时配备了一套完整的电子控制热交换器和天纳克的有源声控系统“Smart Sound”。不过,作为一名记者,我面前的这些钢管让我不得不想起金属贸易战,以及这将对天纳克公司价值 93 亿美元的产品战略产生什么影响。

我转向邀请我来天纳克的公司首席技术官 Ben Patel 博士。“作为一家全球化排气和后处理系统一级供应商,你们总得用传统的钢管吧?”我问,“你们总不能把这些高温器件也换成塑料的吧?”

Patel 博士的神色兴奋起来,他说,“事实上,我们最后有可能真能这么干!目前,我们正在研究如何将复合材料应用至消声箱,其实,不只是消声厢,还有所有系统的‘冷端’部分。”

通过我们的整体式热交换器,系统可以提取热量,并将排气温度降低至可以使用高温热塑性塑料消声箱的水平。“这样一来,我们可以考虑使用更多替代材料了,”Patel 博士表示,“当然,接下来的挑战是,如何将钢材料和复合材料连接起来?这都是我们目前的研究主题。”

除了针对混合动力汽车的创新外,天纳克凭借自身在驾驶控制技术方面的专业知识,为自动和自主驾驶汽车打造一种全新的悬挂系统,甚至包括一些非常激进的设计,根本目的是缓解自动驾驶汽车乘客可能存在的晕车问题。

“一级供应商正在见证汽车行业价值链的转变,向自动驾驶、电力推进和网络互联方向的转变。

IHS Markit 汽车总经理、资深分析师 Michael Robinet 表示,一些着眼当下的公司可能会忽视这些迹象,并按部就班地延续之前的做法。

“而天纳克等公司的眼光却已经放在了十年之后,他们真正理解未来将出现全新的商业模型,而且必须据此调整自身的竞争优势。”Robinet 观察道,“这些转变意味着,供应界不仅需要作为这一转变的积极参与者,更要成为引导转变发生的引导者。”

天纳克曾经是一家估值超 150 亿美元的庞大企业集团,为美国海军建造航空母舰等设备。如今,这家公司正专注于它在移动出行生态系统中需要扮演的最新角色:那就是为市场推出针对汽车和商用车的驾乘控制和后处理/清洁空气系统,其中包括售后市场中一些非常著名的品牌,比如 Monroe、Walker 和 Clevite Elastomers 等。

正如 Patel 博士所称,天纳克的核心技术能力,也就是产品设计、包装和系统集d成可能并不“炫酷”,但也同时受到客户的高度重视。

紧凑装配,产品增值

在电气化和自动化的大背景之下,车辆的装配必须更加紧凑,这也将给工程师带来更多挑战。Patel博士一边指着一款蛇形排气系统原型,一边解释说,电池、逆变器和其他电气元件正在逐步侵占天纳克设备在车辆中拥有的空间。

传统的汽车“冷端”排气系统包括中床谐振器、消声器和 2 根尾管,这将占用大量空间,而且重量也不轻。在此背景下,天纳克工程师为混合动力车打造了新的模块化排气系统,可以提供与传统系统相同的声学和背压性能,但体积更小、质量更轻。

“如今,装配可不是像往常那般容易,更小的设计往往需要极大的创造力。这可以让产品在市场中占据优势,即使它们含有较少的钢材。”Patel 博士表示,“未来,各种车辆系统势必将更加复杂,而相应的工程挑战是将这些更加复杂的系统安装在更小的体积中。这本身就是一种增值。你正在通过自己的努力,为你的顾客解决问题。”

如今,OEM不在会为每个平台提供一种不一样的设计。Patal 博士的团队也旨在打造一种适用于不同汽车平台的标准化模块设计,比如将热交换器与旁通阀都集成到排气管中。对于混合动力汽车而言,这种设计非常具有吸引力,因为这可以满足挡风玻璃的除霜要求,并同时在发动机预热和客舱升温之前加速变速箱的机油预热。

Patel博士说,“我们的方法是提供少数几套标准消声器系统,满足不同汽车厂商的多种发动机/预推进系统的需求。”

“我们可以使用同一套设计和装配方式,并最终利用软件进行最后的声学调整。”Patel 博士指出,“消声箱本身可能无法单独提供产品团队所需的音质,但有了Smart Sound 系统(天纳克在长期声学/降噪研发中的最新成果),我们可以通过增强、减弱或制造新的声音,来调整消音箱的输出。”

天纳克的 Smart Sound 采用了圆顶型紧凑设计,安装在车辆尾气管末端。该系统采用了耐高温的扬声器、控制器和软件算法。

正如一位厂商的工程师所言,Smart Sound 就像是用于调节“尾气声学效果”旋钮。

创新悬挂,大有不同

在如火如荼的自动驾驶汽车革命之中,天纳克的研发团队也看到了重新深刻思考车辆悬挂系统和底盘系统设计的好机会。通常而言,专家普遍认为SAE 4 级和 5 级自动驾驶汽车研发的最大挑战是缓解车上人员的晕车症状,而创新驾乘控制和悬挂系统将是克服这一挑战的关键。Patel 博士承认,“最近的研究发现,四分之一的驾驶员在不开车时会感到晕车,包括我本人。”

未来,当自动驾驶穿梭巴士和私人自动驾驶汽车将更多成为人们的移动客厅和办公室时,车上人员晕车的问题将更加明显,部分原因在于车上部分座椅的方向将与车辆行驶方向相反。

“缓解车上人员可能出现的晕车现象, 是行业必须解决的问题,”Patel 博士断言,“我们已经与该领域内的许多专家进行了讨论,而且美国海军也已就此问题进行了一些重要的研究。在汽车行业历史中,解决晕车问题的需求从未如此迫切。如今,人们已经开始严肃对待晕车问题,而且也已充分意识到,晕车可能成为自动驾驶汽车必须克服的根本问题。

在此背景之下,天纳克开始不断加码对创新悬挂系统的研发投入。通常来说,人们在形容车辆稳定性强时会将车辆比作高铁。天纳克的目的是尽可能地让车上人员免受外界干扰。

“然而,未来车辆将开始执行很多不同任务,我们不能把车辆的移动仅限制在前后方向。”Patel 表示,“例如,车辆可能可以开始左右移动,从而更好地满足停车需求。人们也会对车辆有新的期待。”

在介绍未来汽车底盘稳定性及对前后左右上下方向的控制能力时,Patel 博士不喜欢用轨道车辆来进行类比。在Patel 博士眼中,下一代汽车悬挂系统的动态性能将与“液体”更加相似。

“当你把一杯咖啡洒在桌子上时,咖啡就会以桌面的形状存在。”Patel 博士解释道,“为了彻底消灭车上人员的晕车,我认为这就是未来汽车必须实现的终极目标– 液体般的动态性能。

Patel 博士表示,“即使我们已经到了自动驾驶汽车的世界中,车辆行驶的道路也不会永远平平整整,而且也不会永远只有一种路面。未来,我们希望创造一种可以让乘客享受液体般‘流畅’的乘车体验。”

目前,天纳克推出了大量电子调节式减震产品,这些产品可做到前后向兼容,并且能够根据道路信息输入主动调整悬挂角度。未来针对自动驾驶汽车先进悬挂系统的早期研发也可以从中受益。

五步研究,探索创新方向

Patel 博士透露,天纳克在制定未来技术路线图和相关产品投资计划时采用了一种与一家外部设计创新公司联合进行的独特五步式研究。“在我们合作伙伴的研究过程中,核心就是通过洞察探索创新方向,”Patel 博士表示,“你必须抛出正确的问题,并寻求外部见解,这里的‘外部’不仅仅包括车辆动力学工程师,而且还有未来的道路建设者、轮胎制造商,当然还少不了消费者。”

“我们不只是询问他们希望未来车辆具备哪些功能特征,我们还希望了解他们还有哪些感情方面的要求。”Patel 博士补充道,“举个例子,人们在描述对自动驾驶汽车驾乘体验的期待时,我们经常听到类似‘流畅’这样的词。”

终端用户的多样性也迫使研发工程师必须从不同角度思考车辆的功能和情感属性。Patel博士观察到,“在产品开发的世界里,这种做法并不常见,人们通常只会根据功能要求进行设计和开发。”

天纳克的研究将在 2018 年秋天结束,所有研究成果均将用于天纳克团队口中“创新之路”的规划。

“这些‘创新之路’可以为我们带来新的概念思想,这正是我们现在所处的阶段,”Patal 博士指出,“在 3D 打印技术的帮助下,我们得以证明未来的车辆悬挂系统可能将与当下设计产生巨大差异,从功能上讲也将与当下仅可在垂直方向减震的悬挂系统大有不同。”

这是否意味着目前无处不在的 MacPherson 支柱型悬挂系统将被淘汰?Patel 博士相信,是的,未来会有这么一天。

“举个例子,生活在降雪带的驾驶员希望车辆可以上升至足够的高度,从而跃过比如车道尽头的雪堆。这时,他们需要的可不是区区3 到 4 英寸,而是 18英寸的提升。只有这样,这些驾驶员才能够在天降大雪后仍然把车从自家院子里开出来。”Patel 博士表示,“我们一遍又一遍地倾听客户的意见。然后,我们会问自己这个问题:为了实现这一目标,我们需要做什么?我理解为什么有些人喜欢 SUV,因为 SUV 足够高,但高度并不是所有客户唯一想要的。”

Patel 博士表示,天纳克的研究数据已经确定了数量“惊人”创新途径,并且已经使高级工程团队重新思考有关悬挂系统的传统范例。“这可以让我们领先自动驾驶趋势一步,开始创造与当下车辆属性完全不符的设计。”Patel 博士指出,“我们正在从全新的角度寻找研发和市场机会,这与过去 25 年所看到的情况完全不同。”

未来的自动驾驶汽车特点通常可以用“CASE”来概括,即网络互联(Connected)、自动驾驶(Autonomous)、共享服务(Shared)和电动推进(Electric)。这意味着,车辆也将对悬挂系统和线控制动与转向产生新的需求。从定义上讲,悬挂设计就必须改变。

“我们问自己,'我们该如何重塑产品'?你如何才能抛开所有与制动、转向和悬挂相关的范例?”Patel博士表示说,“我们会开发一个包含所有功能的模块,采用完全不同的设计,所以最终成果将与今天的产品看起来大不相同。”

天纳克的创新之路研究大约收集了 60 个概念,Patel 博士的团队从中选择了 5 个进行研发,并对其中一部分进行了 3D 打印。“当我们开始构建新概念时,我们通常会速战速决,这些概念设计不必完美,仅仅出于验证目的,我们只需要知道这种概念可行即可。”

Patel 博士表示,他的团队很高兴能够成为第一批以科学方式介绍未来自动驾驶汽车数据的人。

“我们将建造与当下市场中完全不同的产品,”Patel 博士断言,“并同时解决自动驾驶系统面临的挑战。”

Exhaust systems, even prototypes fitted with advanced electronics, are not typically the stuff that grabs big headlines. Engineers working on next-gen hybrid propulsion, however, know that a trick set of pipes capable of harvesting waste heat, while sounding sweet—and even creating sound to aid pedestrian safety during low-speed electric operation—is a technology asset worth considering.

Such were my thoughts recently inside Tenneco’s 53-foot demo trailer. On the table in front of me, a neatly designed and TIG-welded exhaust system featured both an integral, electronically controlled heat exchanger and active-acoustic control device the company dubs Smart Sound. But the steel tubing made my journalist’s brain wander to the metals-tariff war and its impact on this $9.3-billion supplier’s product strategy.

I turned to my host, Tenneco chief technology officer Dr. Ben Patel. “How does a global exhaust- and after treatment Tier 1 get around using traditional steel tube?” I asked. “You can’t covert these heat-bearing systems to plastic, right.”

Dr. Patel’s face lit up. “Well, eventually we might be able to! We’re investigating composite materials for muffler boxes—in fact, everything on the ‘cold’ end of the system,” he said.

Using the integral heat exchanger, heat energy is extracted to reduce exhaust temperatures down to where high-temperature thermoplastics can be used to mold the muffler boxes. “That gets us into the range of being able to consider alternative materials,” Dr. Patel said. “Of course, the next challenge becomes, how to join steel and composite material? We’re looking at all of this from a research standpoint.”

Along with new innovations for hybrids, there are also new initiatives to leverage Tenneco’s expertise in ride-control technology for creating new, and in some ways radical, approaches to suspension systems for automated and autonomous vehicles. An aim is to eradicate motion sickness as an issue for AV passengers.

“Scores of Tier 1 suppliers are witnessing a shift in the automotive value chain—towards increased levels of autonomy, electric propulsion and connectivity.

The short-term strategy would be to ignore the signs and continue unabated down the same road,” notes veteran analyst Michael Robinet, the managing director-automotive at IHS Markit.

“Tenneco is among those looking past the next decade—understanding that the business model and their comparative advantage will need to change,” Robinet observes. “Their transformations underscore that the supply community not only needs to be an active participant in this shift, but a leader within it.”

Once a vast $15 billion conglomerate that built (among many other things) aircraft carriers for the U.S. Navy, Tenneco now is precisely focused on where it needs to be in the mobility ecosystem: ride control and aftertreatment/clean-air systems for the automotive and commercial-vehicle sectors. The portfolio includes robust aftermarket brands including Monroe, Walker and Clevite Elastomers.

Tenneco’s core technical competencies—product design, packaging, and systems integration—aren’t glitzy, as Dr. Patel admits. But they’re also highly-prized by customers.

Packaging the value-add

Electrification and autonomy are causing vehicle packages to become tighter and more challenging for engineers, Dr. Patel noted, pointing to the snake-like proto-type exhaust system. The real estate that Tenneco used to “own” under the vehicle is being consumed by batteries, inverters, and other electrical components.

Where a traditional automotive cold-end exhaust system has a mid-bed resonator, a muffler and two tail-pipes—taking up a lot of space and weight—Tenneco engineers have new modular designs for hybrids that provide the same acoustic and back-pressure performance but are measurably smaller and lighter.

“No one is taking packaging for granted anymore. Smaller designs require great creativity and can command a premium in the market, even though they contain less steel,” he said. “The engineering challenge is to make the more complex products of the future work in smaller packages. It’s a value-add; at the end of the day you’re solving problems for your customers.”

Modular designs aimed at standardizing products across multiple vehicle platforms are part of Dr. Patel’s team’s strategy. OEMs are trying to move away from unique designs for every platform. Integrating the heat exchanger with bypass valve into the exhaust tubing is one approach. It’s increasingly attractive for hybrid applications in order to meet windshield-defrost requirements, while accelerating pre-heating of transmission oil ahead of engine warm-up and speeding-up cabin heating.

“Our approach is to offer a finite number of standard muffler packages—to serve OEM platforms that might have multiple engine/pro-pulsion variants with a single system,” Dr. Patel said.

“We can do the final acoustic adjustments in software using the same design and package; the muffler box on its own cannot deliver the sound quality the product team may want,” he noted. “Using our Smart Sound [the latest step in Tenneco’s long development of acoustics/noise cancellation technology] we can adjust the output by either amplifying/creating sound or cancelling it.”

Smart Sound is a compact dome-shaped unit fitted near the end of the tailpipe. It contains a high-temperature-resistant loudspeaker, a controller and software algorithms.

As one OEM engineer puts it, Smart Sound is “the fine-tuning knob for exhaust acoustics.”

Re-thinking suspension tech

The self-driving vehicle revolution presents Tenneco R&D with the opportunity to profoundly re-think vehicle suspension system and chassis system design. Ride control, and suspension in general, will be key to meeting what experts agree is a significant challenge for developers of SAE Level 4 and 5 vehicles: mitigating motion sickness for their occupants. Recent studies have found about 25% of the population suffers from motion sickness when they’re not the driver—”And I’m one of them,” Dr. Patel admits.

Today’s situation will increase exponentially when autonomous shuttles and private AVs, used as mobile living rooms and offices, offer backwards-seating arrangements.

“Motion sickness is an issue that the industry must solve,” he asserts. “We’ve talked with a lot of experts in this area and some important studies have been made by the U.S. Navy on this topic. In automotive, there’s never been a driving force to solve this problem; now, people are looking at it seriously and realize it will become a ‘gating’ issue for AVs.”

The challenge is fueling Tenneco’s most advanced innovation around suspensions. High-speed rail is the common analogy people use to point to where automobiles could be in terms of stability. The goal is to isolate the occupants as much as possible.

“But it’s not just isolating down to one dimension, because vehicles are going to start doing very different things in the future,” he said. “They’ll be capable of moving side-ways to optimize parking, for example. People’s expectations for them will be different than today.”

Dr. Patel doesn’t like to use the rail-car analogy in describing future chassis stability and utmost control of dive, pitch, squat and yaw. He believes a more accurate descriptor for where he sees next-gen vehicle suspension dynamics headed is “liquid like.”

“When you spill a cup of coffee on a table, the liquid takes the form of the surface it’s spilled on,” he explains. “That’s how I believe a vehicle ultimately needs to perform in isolating its occupants from all nausea-causing dynamics. That will come from a liquid-like interface.

“Even in the autonomous future, we’ll never have perfect road surfaces and a single topography. At the end of the day, we want to create an AV driving experience where you are ‘flowing’ on any surface you’re driving over,” he said.

Early investigations into advanced suspensions for future AVs leverages Tenneco’s current electronic shock offerings that are scalable, and capable of actively actuating a suspension corner according to road inputs.

Five-phase study sets the course

Helping to plot Tenneco’s future technology roadmap and related product investments is a unique five-phase study process the company is conducting with an out-side design-innovation firm, Dr. Patel revealed. “Core to our partner’s process for this study is insight-led innovation,” he said. “It forces you to ask the right questions from going out and extracting insights—in this case, not just from traditional vehicle-dynamics engineers, but from people making the roads of the future, making the tires of the future and from consumers.

“We didn’t just ask about the functional features they’d like to have in future vehicles; we also asked what are the emotional attributes they’re looking for,” he added. “We’ve heard a lot of words like ‘smooth’ to describe their expectations for AV ride quality, for example.”

Multiple profiles for end users are forcing the R&D engineers to think differently about functional and emotional attributes. “In the world of product development, that’s not something people commonly do; typically they design and develop to functional requirements,” Dr. Patel observes.

The study is set to conclude in fall 2018. All the ideas and hypotheses that it generated are being formalized into what the Tenneco team calls Innovation Pathways.

“Those pathways lead to concept ideas, which is the phase we’re in,” he noted. “Some of those concept ideas we 3D-printed to demonstrate that the suspension corner of the future is going to look very different and have extremely different functionality than the traditional up-and-down movement and damping that even our active suspensions have today.”

Does this mean the ubiquitous MacPherson strut-type suspension will be obsoleted? At some point, yes, Dr. Patel believes.

“Snow-belt drivers, for example, will want vehicles that can height-extend to clear the plowed-snow berm in the road at the end of their driveways. And extend not just 3-4 inches; they want to extend 18 inches to be able to drive out of their neighborhoods after a big snowfall,” he said. “We’ve heard that over and over from the customers. So, then we ask the question: What would it take to achieve this? It gets to why people like SUVs—they like the height but they don’t want it all the time.”

Tenneco’s study data has generated an “amazing” number of Innovation Pathways, he reports. And, he adds, it has caused the advanced-engineering team to rethink traditional paradigms regarding suspension systems. “It’s allowing us to get out in front of this autonomous-driving trend and start to create the vehicle attributes that are completely different than exist today,” he noted. “We’re picking up an R&D and market opportunity from a completely different vantage point than we’ve seen in the last 25 years.”

The so-called ‘CASE’ future—connected, autonomous, shared, electric—has included engineering concepts that integrate the vehicle drive motors within the hubs. That means the corner, in general, will have propulsion and by-wire braking and steering. By definition, then, suspension design has to change.

“We’re asking ourselves, ‘How do we reinvent the corner’? How do you throw out all the paradigms related to braking, steering and suspension?” Dr. Patel said. “We would approach it by developing a module for the corner that encompasses all of that functionality. Such a module would not look like any products today. Completely different design.”

Some 60 concepts were gleaned from the Tenneco study, from which Dr. Patel’s team selected five, including those that were then 3D-printed. “When we start building them, we’re taking the agile approach—they won’t be perfect. They’re just for proof-of-concept purposes to show it’s all possible.”

Dr. Patel said his team is excited to be among the first to introduce data on the AV future in a scientific way.

“We will build products that are completely different from the landscape,” he asserted, “while solving the problems to enable autonomous driving.”

Author: Lindsay Brooke

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分