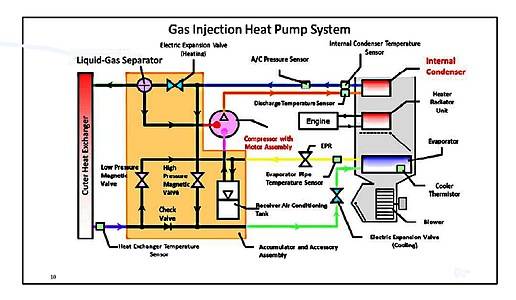

在注气模式下,丰田普锐斯Prime热泵的回路示意图:外部冷凝器在左,内部冷凝器在右。其中,外部冷凝器可以作为一个普通冷凝器,或在有需要时吸收热量。

在注气模式下,丰田普锐斯Prime热泵的回路示意图:外部冷凝器在左,内部冷凝器在右。其中,外部冷凝器可以作为一个普通冷凝器,或在有需要时吸收热量。 制冷剂液气分离器的工作示意图:左边为其他模式,右边为采暖模式。“中压电磁阀(Middle Pressure Magnetic Valve)”将在采暖模式下关闭,推动液体从孔口 (Orifice) 流向外部冷凝器。

制冷剂液气分离器的工作示意图:左边为其他模式,右边为采暖模式。“中压电磁阀(Middle Pressure Magnetic Valve)”将在采暖模式下关闭,推动液体从孔口 (Orifice) 流向外部冷凝器。

在冬季,如果采用传统的电采暖系统,电动汽车的续航里程可能“缩水”60%,在极度严寒的情况下甚至更为严重。因此,丰田 (Toyota) 联手日本电装(Denso),专门设计了一款适用于电动汽车的先进热泵系统。据了解,这款热泵已经安装于丰田普锐斯Prime (Toyota Prius Prime) 插电式混合动力车上。与传统的电加热系统以及日产聆风(Nissan Leaf) 和起亚Soul (Kia Soul) 等电动车型采用的热泵(相对高效,但最低工作温度通常无法低于0°C/32°F)相比,这款先进热泵可以提供明显的性能优化。

在WCX17 – SAE 2017全球汽车年会期间,丰田和电装的研究人员在一项展示环节中表示,与传统热泵相比,丰田普锐斯Prime采用的热泵可节省高达63%的能量,预计可将车辆的续航里程提高21%。

普锐斯Prime PHEV的热泵设计借鉴了一个来自固定式商用热泵的概念,即采用制冷剂液气分离器 (refrigerant liquid-gas separator) 和制冷剂注气回路的设计,从而将热泵有效工作的最低温度极限降低至-10°C/14°F。一般来说,大型固定式热泵液气分离器几乎很难装进车辆的发动机舱内。但据称普锐斯Prime所采用的液气分离器设计紧凑,大小几乎与汽车恒温膨胀阀相差无几。

电动汽车专用热泵?

电动模式下,普锐斯Prime混合动力车型的汽油发动机也可能会启动运行,为车辆提供采暖和除湿功能,但这显然会影响车辆的燃油经济性。为了避免损失,混合动力车型将在电动模式下关闭发动机,由热泵、精密的控制阀系统及液气分离器实现这部分功能。我们不难想象,普锐斯Prime混合动力车采用的这款热泵也同样适用于纯电动车型。

简单来说,热泵性能受温度限制的关键原因之一在于:制冷剂的质量流率 (mass-flow rate)将随着环境温度的变化而变化。与其他汽车热泵一样,Prime热泵也在车辆仪表盘下配置了一款内部冷凝器,作为车舱热量的释放源。Prime热泵选择了电装的涡旋式压缩机单元搭配一个制冷剂气体注入口的设计。在采暖模式下,高温的制冷剂气体将从压缩机排出至内部冷凝器,而后在内部冷凝器中完成部分冷凝,并在这个过程中为车舱提供热量。这点与前置式外部冷凝器有较大不同——在空调 (A/C) 模式下,前置式外部冷凝器将向车外释放热量,以实现制冷剂的冷凝。

随后,经过内部冷凝器部分冷凝的气体将流经一个电子膨胀阀,进行进一步降压,而后流入Prime热泵的超紧凑液气分离器,这也是制冷剂注气系统的关键部分。在采暖模式下,这种设计可以提高热泵回路的性能。

此后,气体将离开液气分离器,进入压缩机进气口。此时,液体制冷剂将流经一条节流通道实现进一步冷凝,而后流入外部冷凝器。在采暖模式下,制冷剂将吸收周围空气的热量,而后流入内部冷凝器(位于仪表盘下方),进一步提升车舱内的温度。

湿度控制挑战

普锐斯Prime的前挡风窗上安装了一个湿度/温度传感器,可以测量玻璃及车舱内的空气温度和湿度。然而,由于在电动模式下,车辆的发动机冷却系统或排气系统并不会产生余热,与压缩机运行产生的热量相结合,因此,实际的湿度控制需求也将给热泵带来挑战。

不过,丰田—电装联合研发的热泵系统还可以提供另一种湿度控制解决方案,而且无需启动发动机。事实上,丰田普锐斯Prime热泵系统拥有串联和并联两套除湿回路,每套回路对应一段特定的温度范围(并联:32-40° F/0-4° C;串联:40-60° F/4-16° C)。其中串联回路可以降低重新加热的需求。

两套回路都采用了蒸发器的设计。蒸发器可以基于位于散热片之间的温度传感器信号,蒸发任何液体制冷剂,并从流经热交换机的空气中吸收热量。此外,这两套除湿回路均可以与车舱采暖回路同时工作。

为了支持车辆空调系统的六种模式,即车舱制冷、采暖、串联除湿、并联除湿、外部热交换机除霜、热泵采暖(用于周边环境温度低时),系统还专门配置了一款湿度传感器。

The loss of winter driving range in electric vehicles equipped with conventional electric heating systems is well-documented—range being reduced by up to 60% and even more in severe cold. The advanced heat pump system in the Toyota Prius Prime plug-in (PHEV), developed in conjunction with Denso, is designed to deliver improvements compared with conventional electric heating and the heat pumps in the Nissan Leaf and Kia Soul EV. Their automotive heat pumps are efficient, but typically operate down only to 0° C/32° F.

The Prius Prime system uses 63% less energy than conventional heating and should extend driving range up to 21%, Toyota and Denso researchers reported in a presentation at the 2017 SAE World Congress (WCX17).

The Prime PHEV incorporates a concept from some static-mount commercial heat pumps: a refrigerant liquid-gas separator and refrigerant gas injection circuit to provide heat pump efficiency down to -10° C/14° F. The large static-mount heat pump separators would be impractical to package underhood. However, the Prime unit was described as similarly compact to an automotive thermostatic expansion valve.

Heat pump coming for EVs?

The Prime gasoline engine could be started and run to provide heat and dehumidification. But this would affect PHEV fuel economy, so the engine is kept off and the heat pump and a complex system of control valves and the liquid-gas separator is used in EV mode. Which indicates Toyota plans this system also for EVs.

A key reason heat pump performance is thermally-limited is because refrigerant mass-flow rate drops with ambient temperature. Like other automotive heat pumps, the Prime's has an under-dashboard internal condenser (the discharge source for all cabin heat). The compressor is a scroll-type Denso unit with a refrigerant gas injection port added. In heating mode the hot, high-temperature refrigerant gas is discharged from the compressor into the internal condenser, where it provides some cabin heat, condensing partly in the process. This contrasts with the front-mounted outer condenser, which in A/C mode condenses refrigerant by giving up heat to the ambient air.

The partly-condensed gas from the internal condenser then flows through an electric expansion valve for further decompression,and into the ultra-compact liquid-gas separator that is a key part of the refrigerant gas injection system. This gives this heat pump circuit extra performance in the heating mode.

From the separator, the gas goes to the compressor inlet. The liquid refrigerant condenses further as it goes through a throttle passage, and flows through to the outer condenser, where in heat mode it absorbs heat from the ambient air and flows to the internal condenser to contribute further to the passenger compartment warming.

Humidity control challenge

The cabin has a humidity/temperature sensor mounted to the windshield (measuring glass and adjacent interior air temperature, plus cabin humidity). However, actual control of dehumidification is another challenge for a heat pump system, because in EV mode there is no waste heat (from engine cooling system or exhaust system) to combine with heat from compressor operation.

However, the Toyota-Denso heat pump system also provides a way without having to start the engine. In fact, there are two circuits, a series and a parallel, each intended for a specific ambient temperature range (32-40° F/0-4° C for parallel circuit, 40-60° F/4-16° C for serial), the latter for the reduced amount of reheating necessary.

Both include a flow path through the evaporator, which vaporizes any liquid refrigerant and absorbs heat from the air going through that heat exchanger, based on signals from a temperature sensor between the fins. And both dehumidification circuits are able to operate in conjunction with cabin heating.

The humidity sensor also is part of the system configuration that provides operation in six different HVAC modes (cabin cooling, cabin heating, serial dehumidification for the cabin (with heating), parallel dehumidification for the cabin (with heating), defrosting the outer heat exchanger, and heat pump-generated cabin heating when ambient temperature is low.

Author: Paul Weissler

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分