对汽车工程师来说,除了面临如火如荼的汽车电气化转型所带来的新挑战之外,噪声、振动与声振粗糙度(NVH)等“老冤家”也并未走远。在过去十年中,汽车行业凭借新的工具和知识成功解决了内燃机汽车的 NVH 挑战,大幅降低了最后关口“紧急修补”的必要性。然而,这些成果从另一方面同时提高了人们对电动汽车和混合动力汽车噪声水平的期望,而值得注意的是,电动推进系统的噪声问题本来就比内燃机车型更难解决。

电动汽车客户在吐槽车辆噪声时总是毫不吝啬。2020 年初,在一个特斯拉车主的在线论坛上,一篇针对“车内噪声评论”的帖子显示,车主对特斯拉在“车内噪声”这一重要汽车衡量指标方面的表现明显不满。以下摘选几个例子:

一位特斯拉 Model 3 的车主写道,“今天,我上 I-15S 公路开了一辆驾驶雷克萨斯 ES 350,这辆车要比特斯拉 Model 3 更安静。”这位车主用分贝仪分别测量了两辆汽车的噪声情况。对比来说,在这条洲际公路上,特斯拉时速70 英里(112.6 公里)的噪声水平为 74 dBA,但雷克萨斯在同等条件下的噪声水平仅为 67 dBA,明显更安静。

一位奥迪的前车主表示:“这辆车 [特斯拉 Model3] 绝对比我以前的 A7 更吵,甚至我都不敢开到时速 110 公里(68 英里)以上。要知道,我平时可是经常开到时速 160 公里(100 英里)的人。更糟糕的是,只要开到时速 110 公里以上,你就别指望用 Spotify 或 Tunein 听任何古典音乐了,你根本听不见,把音乐音量调高只会让情况更糟糕。”

一位来自德克萨斯州的特斯拉车主承认:“没错,Model 3 确实比我之前的那辆车更吵,特别是在道路条件不好的情况下。虽然 Model 3 采用了‘静音’轮胎,但它还是比我妻子的讴歌RDX 和我女儿的奔驰 C300 更吵。”

事实上,这些情况并不是 Model 3 或特斯拉独有的,所有的电动汽车均面临同样的情况。

FEV 北美公司传动系统开发、车辆工程和 NVH 副总裁 Kiran Govindswamy 表示,“尽管电动汽车的整体噪声更低,但面临的 NVH 挑战却更严峻。他说,“电动汽车没有嗡嗡作响的内燃发动机作掩护,因此车内的任何噪声都能听到,很容易引起关注。其中,很大一部分是风声和道路噪音。目前,NVH 工程方面的工作重点是平衡车辆的动力总成、风声和道路噪声的频率。”

NVH 性能是评估车辆质量的关键指标之一,也是电动汽车的重要特征之一。电动推进系统在启动阶段和低速巡航阶段的精致体验是哪怕最顺滑的内燃发动机都无法媲美的。通常,当电动汽车高速运转的情况,车辆的宽带噪音并不高,主要以纯音为主。但随着转速不断拉升,这种声音就会变成恼人的高频噪声。此外,车辆逆变器在 10,000 Hz频率附近工作时也会发出高频噪声。

对此,工程仿真解决方案制造商 Ansys 公司 Physics 业务部首席产品经理 Marius Rosu 表示,“对于电动汽车研发工程师来说,车辆的电机噪声是个大问题。在各种电机速度下,NVH 都无法避免,这不仅可能导致车辆疲劳受损,而且还会给车上人员带来不适。”

电动汽车推进系统的噪声包括来自牵引电机的电磁噪声或来自动能回收(regen)模式下的发电机噪声。“齿轮传动系统也是一样,总是吱吱作响,”Govindswamy 指出,“这是轴和轴承之间摩擦的机械噪声,而且也是汽车厂商创造车辆标志性声音的位置。”

此外,电动汽车驱动单元还有一些其他的噪声,即通常可以隐藏在内燃机车型中的暖通空调(HVAC)噪音,包括电动热泵循环的声音,甚至还有车辆在停止时冷却剂在电池组中晃动的声音,这些声音用户都能听到。对此,工程人员必须进行特殊设计,保证这些系统的工作噪声都不能超过车辆本身的噪声标准。

专家们表示,工程师可以通过结合使用有限元和多车身系统仿真工具,在组件、系统及整车层面进行优化。这些工具可以帮助工程师分析轮系的动力学、轴偏转、外壳结构件以及驱动单元中的电磁力分布情况,从而避免了搭建原型所需的时间和成本,可以极大地便利工程师的降噪、降振工作。

NVH 是一种平衡的艺术:举个例子,你的重点应该是精益求精地调整齿轮的尺寸,从而减少噪声源头的噪声?还是应该专注于驱动单元结构的敏感度,从而使其尽量不要放大进入车舱内和外部世界的噪声?此外,当下,汽车行业为了提高燃油经济性而普遍采用轻质化设计,这也会让车辆更加容易受到 NVH 的影响。

“你必须在架构设计和声学包装研发方面大胆创新,比如精准调整动力总成和悬挂的安装位置等。”FEV 公司的 Govindswamy 表示,“你必须找到一个最佳的安装点,从而最大限度地减少车内设计对噪声的放大效果,”进而控制车辆的 NVH水平。

电动汽车厂商对控制车辆 NVH 的迫切需求催生了一个非常活跃的专业供应商领域:模拟工具提供商。这些提供商已经有针对性的推出了数十个经过验证的仿真工具集,其中最受欢迎的是可以深入研究潜在噪声根本原因的跨学科套装。

位于密歇根州沃特福德市的 Kolano & Saha 联合创始人兼首席顾问 Pranhab Saha 观察到:“针对 NVH 的软件工具往往是基于边界元素、统计能量和气体流动工作的,每个工具都有频率范围的限制。”正因为如此,他说,工程师们已经在各种工具之间建立了“桥梁”,通过配合使用这些工具,从而在更广泛的频率范围内准确预测频率响应情况。

“例如,NVH 声学包装材料通常工作在中高频段,所以这些材料制造商通常会选择统计能量分析工具,”Saha 解释说,“但是,往往存在在较低频率范围中的轮胎腔噪音呢?此时,统计能量分析模型可能就无法发挥作用了,我们必须搭配其他软件工具,从而拓展可以进行准确预测的频率范围。”

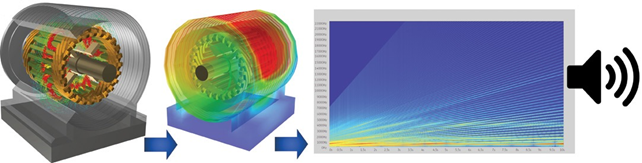

举个例子,电机中的磁力水平是机械和声学分析的关键输入量之一,也是准确预测 NVH 的第一步。对此,比如 Ansys 就可以提供一种模拟电机噪声的模拟工具,可以模拟电机气隙内磁力引起的电机噪声。Rosu 表示,不同平台之间的数据可以通用,比如来自 Ansys Maxwell 的瞬态电磁仿真平台可以创建和测试数字原型,其输出结果则可以直接作为 Ansys Mechanical 平台的输入资料,继续完成谐波振动分析。

Rosu 解释说,“在之前的版本中,我们的软件仅可以生成单个工作点的声谱,但如今已经可以连续在多个速度点上生成声谱,实现所谓的多转速模拟。”

Maxwell 工具还提供了一些仿真模版,支持自动化模拟。在进行模拟时,工程师可能只需要指定一些电机的典型参数,比如相数、极数、插槽、材料、电机尺寸、线圈间距等,后续 Maxwell 工具即可自动生成电机设计。(Maxwell 还允许直接导入外壳和电机型号参数。) Rosu 表示,“Maxwell 可以模拟电机在不同速度、电流、功率、扭矩等各种条件下的工作情况,帮助研发人员更好地了解电机的电磁性能以及机器运行过程中产生的磁力情况。”

在此之后,工程人员还可以将 Maxwell 的输出结果直接输入 Ansys VRXPERIENCE Sound 工具,继续用于合成和评估电机噪声及其对人类感知的影响。通过结合使用 Maxwell、Mechanical 和 VRXPERIENCE Sound 等多种跨学科工具,工程人员可以得到电机的声学特性音频文件,帮助工程师听到电机在不同转速下的声音。Rosu 说:“有了电机的完整声学资料,电气和机械工程师就可以更有针对性的进行设计变更,从而降低控制 NVH 并同时满足电气性能。”

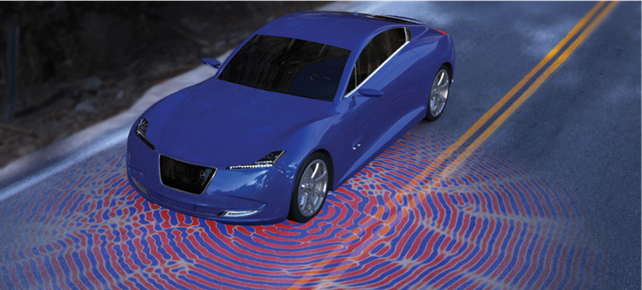

开发工程师认为,电动汽车开发最大的两个挑战是 NVH 和风/轮胎噪音和振动。“内燃发动机车辆也一直都有道路噪声,但道路噪音和发动机内部的一些噪声的频率一致,因此不那么明显。”Saha 表示,“电动汽车中本来就没有轰轰作响的内燃机作掩护,因此任何轮胎/路面噪音都变得更加明显。”

对此,轮胎公司正在开发更安静的轮胎,在轮胎结构中增加更多的弹性和阻尼,来减少辐射噪音。不过,如果静音轮胎还是不能达到车辆的降噪目标时,那车辆原始设备制造商就不得不在车内添加更多加固衬料或声学包装材料,进而增加了车辆的重量和设计复杂度。“自从无内胎轮胎问世以来,轮胎腔噪音的问题从未真正解决。”Saha 指出,“对于电动汽车来说,安静的轮胎更为重要。为了解决 250 到 300 Hz 附近的腔体噪音问题,轮胎厂商已经在轮胎内部进行了大量工作,目的只有一个:尽量降低轮胎的腔体噪音。”

Saha 和其他专家断言,最好的NVH 解决方案一定是从系统层面出发的。达索系统(Dassault Systemes)技术总监 Siva Senthooran 表示:“我们可以在组件级别对各个组件进行 NVH 优化,但问题是当这些经过优化的组件一下子全部放在一起时,往往无法达到客户的NVH 要求。

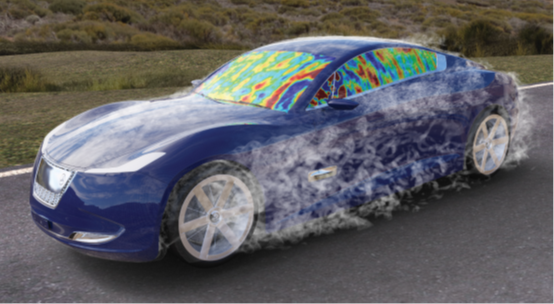

达索系统的 SIMULIA 系列可以提供最全面的 NVH 模拟工具箱。SIMULIA 系列工具箱允许工程师在整个设计过程中,尽可能早地着手进行 NVH 分析,甚至不用等到原型准备好以后。它解决了两个关键问题:噪声源和噪声路径。Senthooran说,SIMULIA 中的 PowerFLOW 套件可以“预测风在车辆周围的流动,以及其将以何种噪声形式进入车舱”。此外,CST 工具也可以用于处理电磁噪声源;达索系统的 Simpack 产品可以预测多体系统产生的力;Abaqus 适用于中低频振动和声学结构耦合方面的模拟;Wave6 可以解决宽频率范围内的噪声传输和辐射路径。

为了分析风噪声,NVH 工程师需要一个真实的外部形状,但粘土模型不适合这种类型的研究,所以团队必须等待声学质量原型就位。“PowerACOUSTICS 设计工具是 PowerFLOW 套件的一部分,主要用于车辆细节尚未最后敲定的早期设计阶段,可以帮助工程师了解不同结构可能会传递多少噪声。”Senthooran 解释说,“有了PowerACOUSTICS 工具,您就可以真实地预测车上人员未来将在车内听到什么。”这样一来,原型设计一旦就位,工程师可以立马着手进行优化。“那时,工程师们已经找到了设计中的大部分问题。”Senthooran 说,“当快到表面设计冻结阶段时,工程师将可以直观地观察到有关 NVH 的问题,并与工作室合作提出解决方案。”

当被问及哪家供应商的何种产品在他的 NVH 工作中发挥了“奠基性”作用时,一位来自底特律三大汽车巨头的电动汽车研发工程师回答到,“FEV 公司的 NVH 数据库。”

作为一家全车工程服务提供商,FEV 会定期为整个汽车行业的新车进行 NVH 性能基准测试,并将测试结果加入一个目前已经涵盖超过 600 款车型和发动机的专有的数据库中,允许客户灵活地使用超过 100 多个指标,用于制定零部件、系统和车辆开发计划的目标。

FEV 的工程师会基于数据库中的数据,为各种指标生成生成“散点图”,展示整个汽车行业目前在该指标方面的表现。Govindswamy 解释说:“各种指标都可以生成散点图,比如发动机或驱动单元的辐射噪声、安装件的隔绝性能或车辆的声学灵敏度功能。”

“NVH 数据库让我们能够帮助客户找准他们的产品在 CAE 和开发测试中的位置,从而更好地支持客户工作。”Govindswamy说,“你们是业内最好的产品吗?中间档次?还是仍有改进的余地?通过找准自己的位置,从而作出更好的开发决策,这是我们工作的核心。”

作者:Lindsay Brooke

本文原发表于

SAE《汽车工程》杂志

Noise, Vibration and Harshness, the engineer’s old nemeses, are among the new paradigms that electrification brings to vehicle development. The industry’s success in mitigating NVH in IC-engine cars and trucks — resulting in fewer 11th-hour “band-aid” countermeasures — was achieved in the last decade with new tools and knowledge. Those gains, however, are now the baseline for tackling what NVH experts say are greater challenges inherent in electric vehicles and hybrids.

EV customers are not hiding their displeasure. A review of the “cabin noise” comments in online Tesla owners’ forums from early 2020 reveal significant dissatisfaction in this important metric. Some examples:

“Today I drove a Lexus ES 350 on I-15S and noticed it is quieter than Tesla 3,” wrote one Model 3 owner, who recorded decibel readings in both cars. While the Tesla netted a 74 dBA at 70 mph (112.6 km/h) on that interstate road, the Lexus’s cabin was notably more serene, at 67 dBA.

Noted a former Audi owner: “It’s [Tesla Model 3] definitely noisier than my former A7 to a point where I dread driving above 110 km/h [68 mph] on the motorway whereas I routinely drove at 160 km/h [100 mph] with the A7. Worse, listening to classical music via Spotify or Tunein gets near to impossible above 110 km/h. Turning the volume up just makes things worse.”

Admitted a Texas-based Tesla owner: “Yes, the 3 cabin is louder than my previous cars, especially on less-than-perfect roads. Even with the ‘quiet’ tires, it’s undoubtedly louder than my wife’s Acura RDX and my daughter’s Mercedes C300.”

Those observations are not unique to the Model 3, or to Tesla. Owners of other EVs who are objective report similar impressions.

“The NVH challenges get tougher with EVs, even though the overall noise levels are lower,” said Kiran Govindswamy, VP of Drivetrain Development, Vehicle Engineering and NVH, with FEV North America. “It puts greater attention on other noise sources because there is no masking of noise as in an IC-engine vehicle. A big part of that is wind and road noise. The focus, in terms of NVH engineering, is balancing the frequencies between powertrain, wind and road noise.”

Favorable NVH behavior is a key indicator of vehicle quality—and a vital attribute in the context of electrified vehicles. Compared with even the silkiest IC-based drivelines, EV propulsion systems inherently exhibit superior refinement during start-up and low speed cruising. At the high rpm where electric-vehicle traction motors typically operate, there is little broadband noise. It’s mostly pure tone, but as rpm rises it becomes a high frequency noise. Power inverters also exhibit high-frequency noise in the range of 10,000 Hz.

“Tonal noise originating from the electric motor is a big concern for engineers designing these vehicles,” said Marius Rosu, lead product manager on the Physics business unit at Ansys, maker of engineering simulation solutions. “At varying motor speeds, NVH is unpleasant and may cause fatigue on the vehicle and discomfort for its occupants. “

EV propulsion system noise includes electromagnetic noise coming from the traction motor, or from the generator when in re-gen mode. “It’s also the geartrain orders, the gear whine,” noted Govindswamy. “It’s the mechanical noise from the shafts and bearings. And it’s the dynamics of how the shafts and housings interact to create the sound signature.”

And there are other audibles unique to EV drive units, typically masked in IC vehicles: HVAC noises. Electric heat pumps cycling. Even the sound of coolant circulating in the battery pack when the vehicle is stopped. All are obvious to the customer and must be engineered so that they operate below the noise ‘floor’ that’s already low in an EV.

That’s where experts say simulation, using a combination of finite-element and multi-body-systems tools, enables engineers to optimize component, system and full-vehicle design. The tools help analyze the dynamics of the gear train, shaft deflection, structural elements of the housing and the electromagnetic forces in the drive unit. The ability to predict both the design performance and the level of vibro-acoustic noise through simulation, without the time and cost of constructing prototypes, plays a significant role in mitigating noise and vibration (N&V) at a primary source.

There are tradeoffs: Should you focus on microgeometry changes to gears, for example, versus desensitizing the drive unit structure so that less noise is amplified into the cabin and the outside world? And the related vehicle structure, as it is made lighter to improve fuel economy, can cause the overall vehicle sensitivity to N&V to become worse.

“It forces you to get more creative with your architecture—including precise powertrain and suspension mounting—and more creative with the sound-package development,” FEV’s Govindswamy said. “You like to identify and design your attachment points to minimize the amount of amplification of the force input,” and hence minimize the level of NVH in vehicle.

Delving deeply into root causes

The urgency to reduce NVH in vehicles has spawned a lively domain of specialist suppliers, offering dozens of proven simulation toolsets for the complex task. The most popular of these are interdisciplinary, multi-physics packages that delve deeply into potential root causes.

“The software tools for NVH are boundary-element based, statistical energy-based, and airflow-based, and each of them have limits in the frequency range,” observed acoustics expert Pranhab Saha, co-founder and Principal Consultant with Kolano & Saha in Waterford, Michigan. Because of this, he said engineers build “bridges” among the various tools that allow them to predict frequency responses within a broader range.

“For example, NVH sound-package materials normally work at mid-to-high frequencies, so the tool their manufacturers use is statistical-energy analysis,” Saha explained. “But what about tire-cavity noise that is at a lower frequency? The statistical-energy-analysis model may not be able to predict this properly. So, there is a need for software tools that can be merged, to enable work in expanded frequency ranges.”

Calculating the magnetic forces in an e-motor, for example, is a critical input for mechanical and acoustic analyses. It is the first step towards predicting NVH. For that process Ansys, for example, offers simulation of e-motor noise caused by the magnetic forces acting inside the motor’s air gap. These excitation forces can be directly transferred from a transient electromagnetic simulation in one platform used to create and test digital prototypes (Ansys Maxwell) to a harmonic vibration analysis in another (Ansys Mechanical), according to Rosu.

“While it had been possible in previous releases to generate an acoustic spectrum for a single operating point, we are now able to walk through a range of rotational speed points in a so-called multi-rpm simulation,” he explained.

Full-motor design is automated using Maxwell’s template-based capabilities. The engineer need only specify the values for typical motor parameters — number of phases and poles, slots, materials, motor dimensions, coil pitch, etc. Once the parameters are specified, Maxwell automatically generates the motor design. (Housing and motor models also can be imported directly into Maxwell.) “Simulation of the motor in Maxwell over wide-ranging operating conditions involving varying speeds, current, power, torque, etc., provides useful insights into the motor’s electromagnetic performance as well as the magnetic forces that are generated during operation of the machine,” Rosu said.

Results are utilized in another tool, Ansys VRXPERIENCE Sound, to synthesize and evaluate motor noise and its impact on human perception. The multiphysics approach combining Maxwell, Mechanical and VRXPERIENCE Sound outputs an audio file of the motor’s acoustic configuration. Engineers can hear its sound at varying rpm. “With the complete acoustic profile of the motor,” Rosu said, “electrical and mechanical engineers can make changes to the design to reduce NVH while satisfying electrical performance requirements.”

OEM engineers developing EVs say their two biggest NVH challenges are wind/tire noise and vibration. “Road noise was always there in IC engine vehicles, but the spectrum of road noise and some of the IC engine noise are all in the same frequencies,” said Saha. “With the IC engine gone [in EVs] the tire-road noise becomes more critical.”

Tire companies are developing quieter tires, adding more elasticity and damping into the tire structure, to reduce radiated noise. When testing shows the tire falling short of noise targets, vehicle OEMs must add stiffeners or sound-package materials inside the vehicle and in the wheelhouse area, which add weight and complexity. “There is also tire cavity noise, which has existed since the advent of tubeless tires,” Saha noted. “It has become more critical with EVs. There is a lot of design and engineering focus inside the tire, to address the cavity noise issue which is around 250-300 Hz. We want to make that less audible.”

He and other experts assert that effective NVH mitigation is best handled at the systems level. “We could optimize at the component level, but once it’s all integrated into a vehicle the NVH behavior often does not meet the customer’s targets,” said Siva Senthooran, technical director for Dassault Systemes.

Dassault’s SIMULIA brand offers a comprehensive simulation toolset for NVH work. It was created to help engineers focus their NVH investigations as far up front in the design stage as possible—before prototypes exist. It addresses the two key bogies: sources and paths. Within SIMULIA, the PowerFLOW suite is used to “predict how the wind behaves as it flows around the vehicle, and the types of sources it will generate going into the cabin,” Senthooran said. For electromagnetic noise sources there is CST. Dassault’s Simpack predicts forces generated by multi-body systems. Abaqus is for vibration and acoustic structural coupling at low to mid frequencies. Wave6 addresses paths of noise transmission and radiation over a broad frequency range.

To analyze wind noise, NVH engineers need an exterior shape. But clay models are not suitable for this type of study, so the team has to wait for an acoustic quality prototype. “PowerACOUSTICS is a design tool that’s part of the PowerFLOW suite, used at an early stage when the design is fluid and you don’t have all of the vehicle details, to find out how much noise transmission you’re going to get from the structure,” Senthooran explained. “With PowerACOUSTICS you can actually predict what somebody is going to hear inside the cabin.” When a design is ready for prototyping is finally ready, engineers have had more time for optimization. “By then, they’ve discovered most of the issues in the design,” he said. “And when the design is close to the surface-freeze stage, engineers have the visual evidence showing the NVH-related issues and worked together with the studio to address the changes.”

Top NVH database supports development

When asked to name a supplier asset that he deems to be “fundamental” for his N&V work, a Detroit-3 body engineer involved with a new EV program replied, “That would be FEV’s NVH database.”

As a full-vehicle engineering services provider, FEV routinely benchmarks new vehicles from across the industry for their NVH behavior.

The benchmark data is fed into a proprietary database the currently covers more than 600 vehicles and engines, with more than 100 metrics used by customers for component, system and vehicle target-setting on development programs.

From the data, FEV engineers generate “scatterband” plots that present the state of the industry for a given metric. “A scatterband field might be radiated noise from an engine, or from a drive unit,” Govindswamy explained. “It might be isolation across mounts, or the vehicle acoustics sensitivity function.

“The NVH database has allowed us to support our customers by telling them where their products stand in both CAE and in the development state for testing,” he said. “Are you best in class? Mid-pack? Or is there room for improvement? Extensive development work supported by benchmarking is at the core of what we do.”

By Lindsay Brooke

SAE Automotive Engineering

在 FEV 公司的消声室中,一部电动汽车驱动装置正在进行 NVH 分析。通常来说,汽车驱动装置的电磁和齿轮噪声时常让开发人员无比抓狂。

在 FEV 公司的消声室中,一部电动汽车驱动装置正在进行 NVH 分析。通常来说,汽车驱动装置的电磁和齿轮噪声时常让开发人员无比抓狂。 Kean Govindswamy 指出,FEV 的汽车行业基准工作可以支持公司全面开展 NVH 开发工作。

Kean Govindswamy 指出,FEV 的汽车行业基准工作可以支持公司全面开展 NVH 开发工作。 达索系统(Dassault Systemes)的 SIMULIA 仿真工具套件旨在帮助工程师直观地观察各种与风声和道路噪声有关的NVH 源和路径,从而优化车内的噪声环境。

达索系统(Dassault Systemes)的 SIMULIA 仿真工具套件旨在帮助工程师直观地观察各种与风声和道路噪声有关的NVH 源和路径,从而优化车内的噪声环境。 Ansys 的 NVH 工具平台包括 Maxwell、Motion、MAPDL 和 Dyna 等多个系列,旨在简化开发人员的工作流程,可以以更简洁的方式解决各个频段内的振动声学问题,并减少所需的原型迭代数量。

Ansys 的 NVH 工具平台包括 Maxwell、Motion、MAPDL 和 Dyna 等多个系列,旨在简化开发人员的工作流程,可以以更简洁的方式解决各个频段内的振动声学问题,并减少所需的原型迭代数量。 轮胎制造商、电动汽车工程师和仿真工具提供商也在重新审视轮胎的腔内噪声问题以及轮胎与路面之间的摩擦噪声问题。

轮胎制造商、电动汽车工程师和仿真工具提供商也在重新审视轮胎的腔内噪声问题以及轮胎与路面之间的摩擦噪声问题。