凯迪拉克推出全新4.2 升 V8 发动机,专为2019 款 CT6 系列设计。为了满足运动版CT6 对性能的高要求,这款双涡轮增压 DOHC V8 发动机的功率输出高达 550 hp,扭矩输出则达 627 lb·ft。(图片来源:通用汽车)

凯迪拉克推出全新4.2 升 V8 发动机,专为2019 款 CT6 系列设计。为了满足运动版CT6 对性能的高要求,这款双涡轮增压 DOHC V8 发动机的功率输出高达 550 hp,扭矩输出则达 627 lb·ft。(图片来源:通用汽车)

重新设计的2019款凯迪拉克CT6 V-Sport 采用了Escala概念车的设计理念,并将采用全新设计的4.2L V8高性能版发动机。

重新设计的2019款凯迪拉克CT6 V-Sport 采用了Escala概念车的设计理念,并将采用全新设计的4.2L V8高性能版发动机。

从最近的情况来看,汽车制造商似乎并未叫停对内燃发动机的投资。举个例子,通用汽车 (General Motors) 旗下豪车品牌凯迪拉克 (Cadillac) 即耗时 4 年时间,隆重推出了一款全新 V8 发动机。按照计划,凯迪拉克旗舰车型运动版 CT6 将自 2019 年上半年起,独家使用该款 4.2 升 DOHC V8 双涡轮增压发动机。然而,我们不难想象,未来通用汽车将势必还有至少一款关键车型也采用这款 V8 发动机。

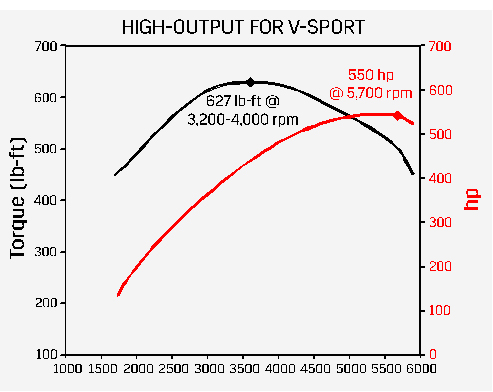

凯迪拉克 V8 发动机首席工程师 Jordan Lee 向少数媒体展示了公司最新 V8 发动机的架构。Lee 表示,这款发动机继承了凯迪拉克品牌对与众不同和卓越性能的一贯追求,完美地将精致与性能融为一体。升级后的 2019 款 CT6 产品线将为客户带来两种搭配不同配置 V8 发动机的版本,其中一款专为运动车型设计,5,700 转时可输出 550 hp 马力,3200 到 4000 转时可取得 627 lb·ft(850 N·m)的峰值扭矩。

这款全新铝制 V8 的标准版本预计可在 5,000 到 5,200 转时输出 500 hp 马力,并在 2,600 到 4,600 转时输出 553 lb·ft (700 N·m) 扭矩。这款发动机的副总工程师 John Rydzewski 表示,发动机达到这些数据的前提是使用优质的无铅汽油。这款发动机采用了高压 (5,076-psi) 直喷系统,压缩比为 9.8:1。对此,通用工程师告诉《汽车工程》,直喷系统的压力相对较高,这意味着不必采用目前非常流行的“直喷+进气口喷射”的组合设计。

别具一格的 V 型设计

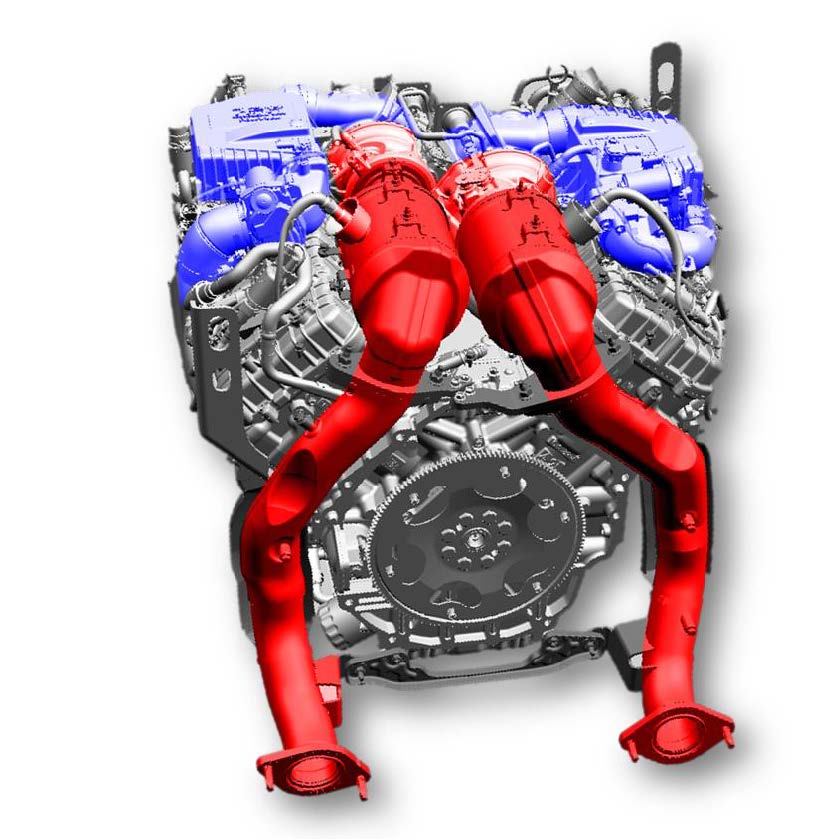

这款全新 4.2 L V8 发动机的标志性特征也许就是“逆向”开口设计:排气口位于发动机 90 度 V形结构的内侧,而进气口则将从 V形结构的外侧将空气输送进入气缸。

事实上,这并非通用汽车的首款量产 V8 发动机,但却是凯迪拉克发动机首次将这一概念发展到新的极致:公司不仅将双涡管涡轮增压器安装至发动机的 V 形结构中(作为排气歧管的整体组成部分之一),而且还将定容催化转换器也安装在此处,重新定义了催化过程中的“紧耦合(close-couple)”概念。车辆的催化转化器为了方便氧气传感器的安装而钻了孔,名副其实地“坐”在发动机之上。这意味着,尾气一旦离开转化器,则将在此后通往后保杠双排气管路的道路上畅通无阻,不受任何组件的限制。

Rydzewski 表示,“Hot V”设计是“最有效的优化系统涡轮响应速度的方法”。

紧凑型双涡管涡轮增压器由三菱重工 (MHI) 提供,且具有电子废气门控制功能;通用汽车表示,这款涡轮增压器采用了铝钛合金材料,重量只有铬镍铁合金同类设计的一半,最高转速可达 170,000 转。涡轮增压器的最大增压范围为 20 psi,液化中冷器的设计则最多可以协助每个气缸组抑制 20 kW 的散发热量,据称最高可使进气温度降低 130 华氏度(54 摄氏度)。

Lee 补充说,在全新 V8 的研发中,协助发动机涡轮排出所产生的巨大热量是最具挑战性的任务之一。Lee 表示,“从一张白纸完全开始新的设计”可以让我们采用新的热量管理解决方案,让 V8 一直维持在可接受的温度范围之内,特别是在发动机已经关闭但涡轮增压器和催化器中仍存在大量热量的一段时间内。Lee 表示,当发动机停止后,车辆的前冷却风机将继续循环发动机周围的空气,而可变流量水泵也将继续泵送冷却液,直至车辆的冷却需求完全得到满足。

紧凑安装

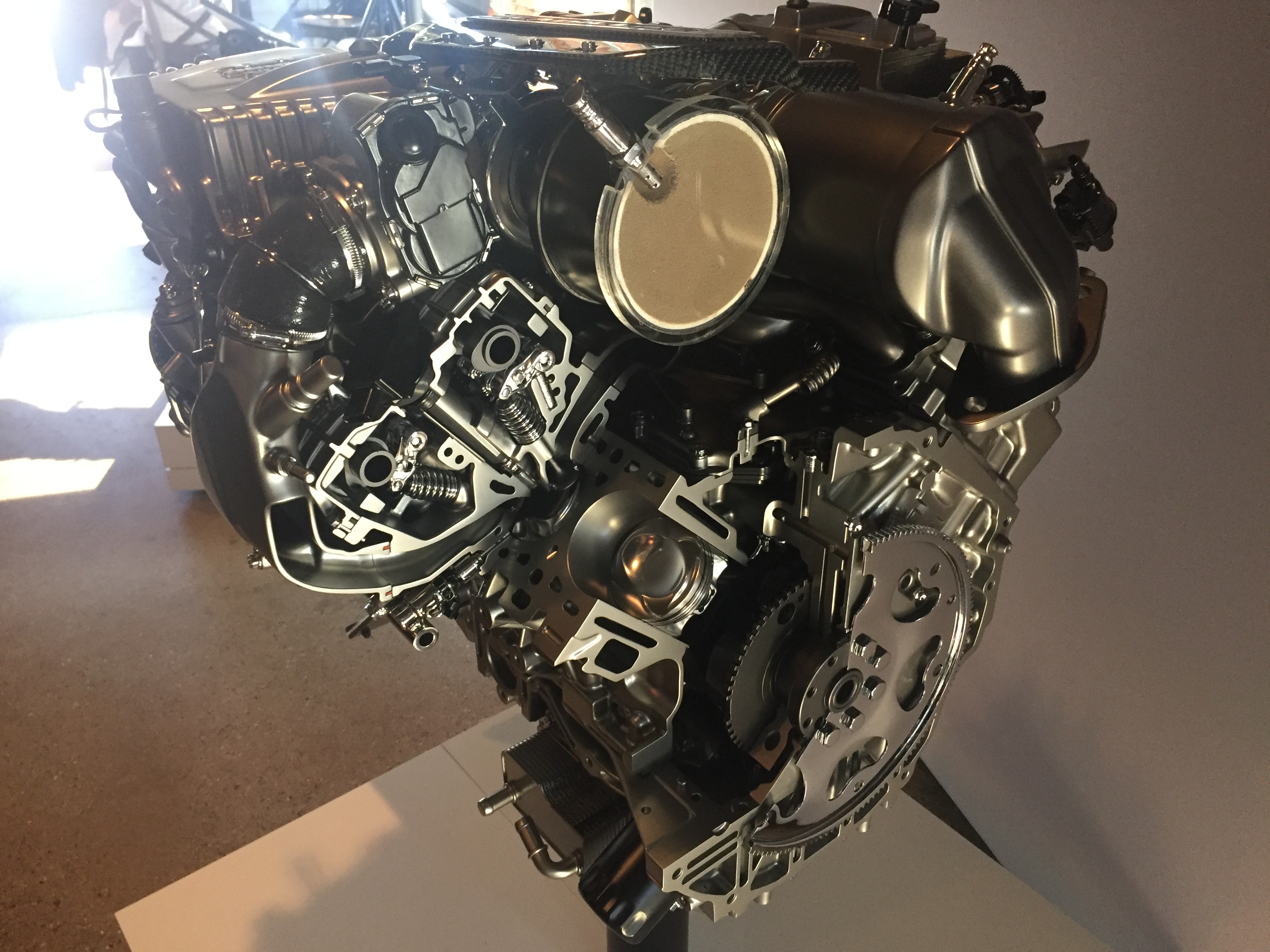

Lee 表示,凯迪拉克新款 V8 发动机各气缸之间的间距仅为 10 毫米(0.4 英寸),因此尽管排量达 4.2 L,但安装尺寸却比之前版本短 50 毫米(2 英寸)。各气缸的内径为 86 毫米,冲程为 90.2 毫米;Lee 表示,各气缸间相对狭窄的安装位置并不会限制气缸本身的内径。

这款 V8 的六螺栓主轴承气缸体采用了 A319 铝材料搭配压入式铁质内衬的设计,气缸盖采用了 Rotocast 的 356 铝材,带有 36 毫米进气阀和 29 毫米的钠填充排气阀,曲轴和连杆均采用了锻钢材料。

节油措施

尽管 4.2 L V8 发动机项目的主要目标时优化性能,但这款发动机也采用了多种节能技术。

其中,最重要的是首次采用了一款专为通用 DOHC V8 发动机设计的主动燃料管理系统。在合适的条件下,该系统可以实现气缸钝化功能,即关闭发动机一侧气缸靠外的 2 个汽缸和另一侧气缸靠内的 2 个汽缸。在可变气门正时系统中,排气门最大张合角度为 55 度,进气门的最大张合角度则为 70 度。此外,新型V8 还采用了一款新型 E86 发动机管理控制器,对各种发动机运行参数进行管理。

这款新发动机还采用了启停装置以提高节油效果,但 Lee 表示现在公布发动机的燃油经济性数据还为时过早。

对于 2019 款 CT6 而言,无论采用何种版本的 V8 发动机,车辆均将配备通用汽车的 Hydra-Matic 10 速自动变速器、性能先决换挡/加速系统 (PAS / PAL) 及方向盘换档控制系统。车辆采用了电子中控台选择器设计,不再使用传统的物理连接,因此可以腾出更大车内空间。

此外,这款 CT6 还会标配全轮驱动系统 (AWD),更好地发挥 V8 发动机的强劲性能。AWD 分动箱将与发动机的铸铝油底壳进行整体安装。

肯塔基州手工打造

凯迪拉克的最新 4.2 L V8 发动机将在通用汽车位于肯塔基州 Bowling Green 市的高性能生产中心 (Performance Build Center) 手工装配而成。值得一提的是,这里也是雪佛兰 Corvette 及其搭配的多款手工打造发动机的组装场地。

事实上,业内一直有传言称新一代 Corvette 可能会转而采用全新的 V8 发动机,而非该车型长期使用的小型 OHV V8 发动机,甚至还有可能增加或直接转向一种新的先进中型发动机车辆架构。新款凯迪拉克 V8 发动机的动力和扭矩“潜力”显而易见,且对生产场地的安排也让人充满遐想——这款新型发动机是否会最终登陆雪佛兰 Corvette 或其他凯迪拉克车型?

正如大家所料,通用汽车的动力总成工程师并未直接回应这种猜测,但的确表示新的凯迪拉克V8“可能是未来公司多个其他项目的基础”,这意味着通用总工程师并未一口否认这种可能性。

In the latest signal that automakers aren’t shutting off investment in internal-combustion just yet, General Motors’ Cadillac premium-vehicle brand unwrapped an all-new V8 roughly four years in the making. Cadillac will begin with exclusive use of the twin-turbocharged 4.2-L DOHC V8 starting in the first half of 2019 with a high-performance V-Sport variant of the CT6 flagship sedan—but it’s easy to speculate the V8 could be earmarked for future use by at least one other important GM model.

Revealing the new V8 architecture to a small media group, Jordan Lee, chief engineer for Cadillac V8 engines, said the engine is intended to underscore the Cadillac brand’s exclusivity and performance heritage and deliver an appropriate blend of high performance and refinement. The updated 2019 CT6 lineup will offer two variants of the new V8: a high-output version for the V-Sport model that generates an estimated 550 hp at 5,700 rpm and peak torque of 627 lb·ft (850 N·m) from 3,200-4,000 rpm.

The standard variant of the all-aluminum V8 is projected to produce 500 hp at 5,000-5,200 rpm and 553 lb·ft (700 N·m) from 2,600-4,600 rpm. Assistant chief engineer John Rydzewski said premium-unleaded fuel is required to achieve those output figures. The fueling system is a high-pressure (5,076-psi) direct-injection system and compression ratio is 9.8:1. Engineers told Automotive Engineering that the comparatively high pressure of the DI system meant they could forego the current trend of coupling direct- and port-injection fuelling systems.

The “Hot V” difference

Perhaps the new 4.2-L V8’s signature design feature is “reverse” porting that sees the exhaust ports on the inside of the engine’s 90-degree vee, with intake charge entering the cylinders from ports on the outside of the vee.

This is not a first for production-vehicle V8s, but the Cadillac engine takes the concept to a new extreme, locating not only both twin-scroll turbochargers in the engine vee (as integral parts of each exhaust manifold), but also the single-volume catalytic converters, bringing a new definition to the term “close-coupled” in relation to the catalysts. The catalytic converters, drilled for inclusion of an oxygen sensor, literally sit atop the engine and all but inside its valley. Once the exhaust leaves the converter, there are no other components or restrictions on the route to the dual exhaust tips at the rear bumper.

Rydzewski said the “Hot V” design is “the most effective way to optimize the turbo responsiveness of the system.”

The compact twin-scroll turbochargers are supplied by Mitsubishi Heavy Industries (MHI) and feature electronic wastegate control; the titanium-aluminide turbines can spin at up to 170,000 rpm and are half the weight of a similar design in Inconel material, GM said. Maximum boost pressure is 20 psi and the air-to-liquid intercooler design can reject up to 20 kW of heat per cylinder bank, dropping intake-charge temperature by as much as 130 deg (74 C), Cadillac said.

Extracting the immense heat developed in the engine vee was one of the most challenging aspects of the new V8’s development, added Lee. He said the clean-sheet design allowed new thermal-management solutions to assure the V8 maintains acceptable temperatures, particularly after the engine is shut down and the turbochargers and catalysts retain immense amounts of heat. Lee said the single front cooling fan continues to circulate ambient air over and around the engine, while the variable-flow water pump also circulates coolant for whatever time is required after engine shut-down.

Compact packaging

With cylinder bores just 10 mm (0.4 in) apart, Cadillac’s new V8 packages its 4.2 liters of displacement in a footprint that’s about 50 mm (2 in) shorter than usual, said Lee. Bore is 86 mm and stroke is 90.2 mm; Lee said the tight spacing between bores did not dictate a limitation on bore size.

The V8’s 6-bolt main-bearing cylinder block is A319 aluminum with pressed-in iron liners and the cylinder heads are Rotocast-supplied 356 aluminum, with 36 mm intake valves and sodium-filled 29-mm exhaust valves. The crankshaft is forged steel, as are the connecting rods.

Fuel-saving measures

Performance and refinement were paramount design targets for the 4.2-L V8, but the architecture includes several fuel-saving technologies.

Most significant is Active Fuel Management in its first use for a GM-made DOHC V8. The setup operates the engine in 4-cyl. mode when appropriate, shutting down the outboard two cylinders of one bank and the inner two cylinders of the other engine bank. The variable valve timing allows for 55 deg of authority for exhaust valves and 70 deg of authority for intake. This and other engine-operating parameters are governed by a new E86 engine-management controller.

The new engine also incorporates start-stop for increased fuel saving, although Lee said it remains too early to release projected fuel-economy figures.

For the 2019 CT6, either variant of the new V8 will be coupled with the GM Hydra-Matic 10-speed automatic transmission with GM’s Performance Algorithm Shifting/Performance Algorithm Liftfoot (PAS/PAL) and steering-wheel paddle shift control. An electronic console selector frees interior space by eliminating mechanical linkages.

Additionally, the CT6 applications will include all-wheel-drive as standard fitment with the new V8. The AWD transfer case is mounted integrally with the engine’s cast-aluminum oil pan.

Hand-made in Kentucky

Cadillac’s new 4.2-L V8 will be hand-assembled at GM’s Performance Build Center in Bowling Green, Kentucky. This is the site of assembly for Chevrolet’s Corvette and certain hand-built engines for that model.

It has long been rumoured that the next-generation Corvette could be powered by a new V8 engine—other than its longstanding small-block OHV V8—in addition to the possibility of either adding or wholly moving to an advanced mid-engine vehicle architecture. With the obvious power and torque “headroom” of the new Cadillac V8 and its new assembly location in the same plant where the Corvette and special Corvette engines are built, many will find it logical to speculate that Cadillac’s new V8 architecture is foreshadowing its eventual use for the Corvette—or other Cadillac models.

The company’s powertrain engineers of course aren’t directly addressing that speculation, but Lee didn’t exactly throw cold water when telling the media that the new Cadillac V8 “could be the basis for a lot of other things going forward.”

Author: Bill Visnic

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Bill Visnic

- 行业:汽车

- 主题:制造零部件动力与推进力质量、可靠性与耐久性车辆与性能