最近,在ZF TRW举行的一次技术演示试驾中,公司高级负责人Andrew Whydell正在介绍公司的SAE 2级自动技术。此时,Whydell的手并未握着方向盘,脚也没有踩在油门刹车上。他说,自动公路驾驶功能“不仅可以免除驾驶员进行长时间驾驶时的疲劳,而且还能通过保持车道和车距,提高车辆的安全性。”

最近,在ZF TRW举行的一次技术演示试驾中,公司高级负责人Andrew Whydell正在介绍公司的SAE 2级自动技术。此时,Whydell的手并未握着方向盘,脚也没有踩在油门刹车上。他说,自动公路驾驶功能“不仅可以免除驾驶员进行长时间驾驶时的疲劳,而且还能通过保持车道和车距,提高车辆的安全性。”  在ZF TRW全新电子技术中心的专用实验室中,技术员Mike Babala演示了汽车摄像头的校准过程,校准的目的是保证镜头有效并且准确地聚焦。

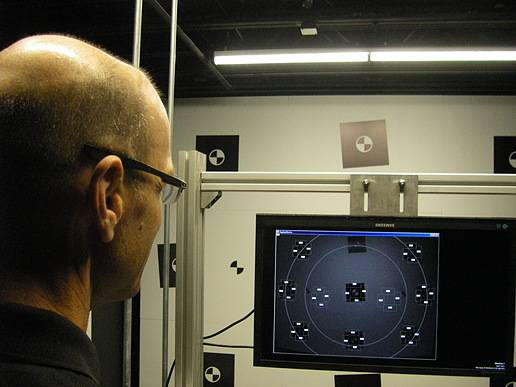

在ZF TRW全新电子技术中心的专用实验室中,技术员Mike Babala演示了汽车摄像头的校准过程,校准的目的是保证镜头有效并且准确地聚焦。 在ZF TRW的新电子技术中心中,技术员Matt Warmuth在完成环境测试后,正在检查一支镜头的质量和性能特征。

在ZF TRW的新电子技术中心中,技术员Matt Warmuth在完成环境测试后,正在检查一支镜头的质量和性能特征。

近日,采埃孚天合集团(ZF TRW)的全新全球技术中心在密歇根州法明顿希尔斯市正式成立。新技术中心内专门设置的“卓越摄像头实验室”凸显了视觉系统技术在ZF TRW的重要地位,也反映了这种技术在自动驾驶系统中扮演的关键角色。

主/被动安全技术部、高级驾驶员协助系统(ADAS)业务高级副总裁Brian Loh表示,“随着我们高级驾驶员辅助系统业务的不断增长,我们需要进行更大量的开发与测试。在新中心的帮助下,我们现在可以更好地完成这项工作。”

近日,在这所全球电子技术中心的开幕仪式上,Loh与其他几位技术人员接受了《汽车工程》的采访。

据了解,这座全球电子技术中心耗资300万美元打造,占地15,886平方米,拥有超过600名工程师和支持人员。该中心内拥有3,252平方米的实验空间,可进行射频、主动安全及被动安全等多种技术产品的研究与测试,其中就包括公司的单镜与多镜版S-Cam系列摄像头。

“目前,该中心正在研发一款适用于TriCam系统的三焦距镜头。”Loh说,“这种镜头支持近焦、中焦和广角3个焦距模式,传感范围比传统的单晶摄像头宽很多。”据了解,TriCam将于2018年中期将进入生产,届时将登陆一些支持自动驾驶功能的车辆。

ZF TRW光学工程部高级技术专家Mike Babala表示,新中心拥有集团内部唯一一间光学目标实验室,这可帮助技术专家寻找并校准摄像头的焦点。

Babala解释道,“我们核心光学团队的工作是确保镜头前方的一切事物均能在镜头后方,也就是图像中得到准确体现,我们也采用了基于对象的镜头。”

该中心内的光学目标室处于一个严格控制的环境中,这与公司之前用车库改建的操作间完全不同。“过去,我们在进行实验时必须特别小心,不能让光从门缝或墙壁中渗过来,从而防止眩光的产生,保证实验的顺利进行。”Babala补充说,“新的实验室对光的控制非常严格,不会出现渗光的问题。”

ADAS工程总监Raad Konja表示,我们必须依赖可重复性测试,才能开发真正稳健可靠的摄像系统。他说,“一切都是标准化的,因此我们每次的测试均处于一个变量可控的环境中。光学摄像头系统主要分为三个部分,镜头、成像器以及图像电子转化设备,因此我们在进行优化时,只需要对这几种组件进行调整,然后观察改变后的组件会给整个系统带来什么影响。”

在系统开发的过程中,ZF TRW的工程师选择了四辆欧宝Insignia轿车协助测试,这些测试车均配备了ZF的自动制动与转向系统。Loh表示,“我们为测试车辆配置了多个长距和短距雷达,以及一个前向摄像头,这些系统均将遵循公司内部开发的算法相互配合、协同工作。”

按照SAE International国际自动机工程师学会的定义,2级自动驾驶车辆功能应能够在公路驾驶环境下支持驾驶员的“脱手”操作,也就是说驾驶员不用亲自控制方向盘和油门刹车,而且还可以在有需要时启动自动变道功能。

据了解,ZF TRW的工程师计划提升这些测试车辆的自动功能,使其满足SAE对3级或4级自动驾驶技术的定义。Loh说,“我们开始使用更多的复杂传感器。此外,我们还在Ibeo汽车系统公司持股40%,正在尝试为车辆搭配固态激光雷达系统。”

在这所新技术中心的揭幕仪式上,在场媒体有幸与ZF TRW产品规划与汽车系统战略部总监Andrew Whydell一起进行试驾。据了解,Whydell所在的部门也负责公司自动驾驶方面的活动。

Whydell对车上的媒体表示,“我们展示的技术已经接近量产水平,预计大约将在2018年进入美国的乘用车市场。”此时,Whydell“驾驶”的车辆正在SAE2级自动模式下,行驶在底特律的公路之上。

With its newest work space designated a center of excellence for cameras, ZF TRWunderscores the critical role that vision-systems technology plays in automated driving.

“As our Advanced Driver Assistance System (ADAS) business grows, we need to do a higher volume of development and testing. With this new facility, we’re now much better suited to do that work,” said Brian Loh, Senior Vice President of ADAS in the Active & Passive Safety Technology Division.

Loh and other ZF TRW technologists spoke with Automotive Engineering at the opening of the company’s newly opened $30 million Global Electronics Technical Center in Farmington Hills, MI.

The 171,000 ft2 (15,886 m2) center, staffed by more than 600 engineers and support staff, contains 35,000 ft2 (3252ft 2) of lab space for radio frequency, passive and active safety products, including the company’s S-Cam family of cameras in single- and multiple-lens versions.

“This facility is where the technology is being developed for our TriCam, a tri-focal lens camera with near-, mid-, and fisheye views," Loh said. "With the combination of all three of these lenses, the sensing envelope is much broader than a traditional single lens camera.” The TriCam is slated to enter production in mid-2018 for application on vehicles with automated driving capability.

As the only R&D lab of its kind within ZF TRW, the electronics tech center’s optics-target room enables technical specialists to access a camera’s focus and alignment, according to Mike Babala, Senior Technical Specialist for Optics Engineering.

“Our job in the core optics group is to make sure everything in front of the lens, which is object-based, gets accurately represented behind the lens, which is image space,” Babala explained.

The optics target room is a highly controlled environment, unlike the supplier’s former work space in a converted garage bay. “In the past we had to take special care to be sure that stray light didn’t enter the room from underneath the doors or walls and cause glare on the optic wall targets during measurements,” Babala said, adding, “There’s no stray light in this light-tight lab.”

Raad Konja, Director of ADAS Engineering, said developing a robust and reliable camera system relies on repeatable measurements. “Everything is standardized, so there’s no drift from test to test. The only thing that needs to change are the improvements that we drive into our optical path, which is comprised of a lens, an imager, and the technology that converts the images into electronics,” Konja said.

For the purpose of systems development, the engineers are using four Opel Insignia vehicles equipped with ZF TRW braking and steering. "We’ve added long- and short-range radars and a forward-looking camera with everything cooperatively operating on internally developed algorithms,” Loh said. The cars' SAE Level 2 technologies permit hands-free steering and foot-off pedal control at highway speeds, including lane changes prompted by the driver using the turn indicator.

The roadmap for ZF TRW engineers is to take these R&D cars to SAE Levels 3 and 4 capability. “We’re adding more sophisticated sensors, and now with our 40% stake in Ibeo Automotive Systems GmbH we’re working to add solid-state LiDAR,” Loh said.

Media who attended the new facility's opening were given the opportunity to ride with Andrew Whydell, the company's Director of Product Planning and Strategy for Vehicle Systems, which includes the company’s automated driving activities.

“We’re demonstrating technologies that are close to production, and I would say around 2018 you’ll start to see these technologies in the U.S. on passenger vehicles,” Whydell said while the Insignia was traveling at highway speeds on a metro Detroit expressway in its SAE Level 2 automated mode.

Author: Kami Buchholz

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Kami Buchholz

- 行业:汽车

- 主题:噪声、振动与声振粗糙度零部件动力与推进力质量、可靠性与耐久性电气电子与航空电子测试与检验