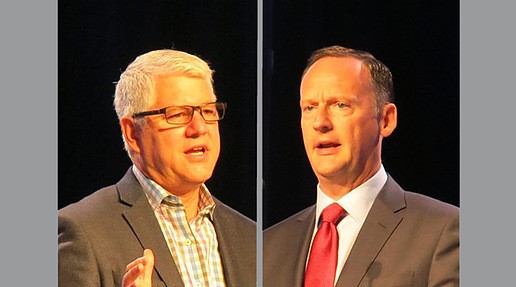

本田的Robert Bienenfeld(左)和通用汽车的Dan Nicholson在有关提高燃油辛烷值,从而优化发动机能效方面的看法一致。

本田的Robert Bienenfeld(左)和通用汽车的Dan Nicholson在有关提高燃油辛烷值,从而优化发动机能效方面的看法一致。

在密歇根州特拉弗斯城举行的2016年CAR管理研讨会(CAR Management Briefing Seminars)上,通用和本田的高层领导均表示,为了优化现阶段仍在研发之中的先进内燃机,提高美国汽油辛烷值势在必行。在这两位高管发表观点之后,美国环保局交通和空气质量办公室 (Office of Transportation and Air Quality for the U.S. EPA)主任Chris Grundler也给出了积极回应,但并未作出最终结论。

在一场有关未来动力系统的嘉宾讨论中,通用汽车全球推进系统副总裁DanNicholson和本田汽车美国公司环境与能源战略助理副总裁Robert Bienenfeld一致认为,汽车行业必须推动提升美国汽油中的“最低”辛烷值。

“通过‘从石油到汽油’生产过程和对发动机效率的全面研究分析,推广高辛烷值汽油是最经济的二氧化碳减排解决方案之一,”Nicholson告诉CAR大会中的嘉宾讨论主持人Brett Smith,“我们在设计时,必须考虑燃油和发动机的匹配。如果完全撇开燃油不谈,

Nicholson补充道,经过专门设计的辛烷值更高的燃料“可以带来很高的经济效益。”他说,美国能源部的一项分析证明,提高燃油辛烷值可以提高发动机的燃烧效率,并降低CO2排放。

本田的Bienenfeld也介绍说,高级涡轮增压发动机在高负载设备及其他大型车辆应用中,使用高辛烷值燃料颇具优势。他同时指出,增压内燃机车辆、混合动力车及燃料电池车都在本田未来的发展规划之中。Nicholson则着重介绍了提高奥托循环压缩比的趋势,并表示他的工程团队也在研究米勒循环燃烧技术,以及“一路证明了自己的”涡轮增压技术。

Nicholson表示,他很看好柴油发动机在美国的应用潜力,“这里是全球少数几个压燃式发动机的增长市场之一。”

Bienenfeld表示,本田认为“如果[现行]标准停留在2025年的水平”,那么采用48V混合动力技术将是一种非常经济实惠的选择。

美国环保署官员Grundler在同一天晚些时候举行会议中指出,环保署正在参与美国能源部开展的Optima项目,进行有关未来燃油的相关研究,而且还专门设置了一个汽油辛烷值研究特别工作组。“燃油的变化并不在TAR(技术评估报告,即当下CAFE规定中期审阅的一部分)的评估范围之内,”他示意,“只要不会增加温室气体排放”,就可以考虑在2025年后提高汽油燃料的辛烷值。

Optima项目旨在为一系列轻型、中型和重型车辆发动机开发最适合的燃料。美国橡树岭国家实验室燃料、发动机与排放研究中心主任Wagner博士曾在SAE高效发动机研讨会上宣布,Optima项目的目标是在2030年前,将每辆汽车的平均汽油燃料消耗降低30%。这是汽油和乙醇生产商与汽车产业协同合作的成果。

美国能源部表示,如果可以实现Optima项目目标,则可将全美的原油消耗降低45亿桶,从而为消费者节约500亿美元的燃油支出。

目前,2020年新型燃烧策略主要通过针对先进米勒循环、稀燃和化学计量运行等燃烧技术的研究,从而实现50%甚至更高的峰值燃油效率。为了实现这一目标,提高燃油的“最低”辛烷值至关重要。橡树岭国家实验室的Wagner博士在SAE研讨会上表示,一些多缸测试发动机的最高燃油效率可以突破55%。

马自达Skyactiv项目旨在结合奥托燃烧循环和柴油机燃烧循环的各自优势,并最终取得最佳燃烧性能。该项目分G1、G2和G3三个阶段分步推进,并最终在G3阶段实现:在λ为2.5时,取得18:1的压缩比,即通过设定理想的HCCI(均质充量压缩点火)压强和温度,实现40%的热效率提升。

在欧洲地区,与压缩比在9.0到9.5:1的发动机使用的中档95-RON汽油相比,分布广泛的“超优”102-RON汽油有助于为压缩比高于11.5:1的发动机取得10%的燃油经济性提升。

作者:Lindsay Brooke

来源:SAE《汽车工程》杂志

翻译:SAE 中国办公室

GM, Honda execs agree: Higher octane gas needed to optimize ICE efficiency

Raising the octane level of pump gasoline in the U.S. is integral to optimizing advanced combustion engines now in development, said GM and Honda executives at the 2016 CAR Management Briefing Seminars in Traverse City, MI. Their comments prompted positive but non-committal comments from Chris Grundler, Director of the Office of Transportation and Air Quality for the U.S. EPA.

During a panel discussion on future powertrains, Dan Nicholson, VP of Global Propulsion Systems at GM, and Robert Bienenfeld, Assistant VP of Environment and Energy Strategy at American Honda, agreed that the industry must push for a higher fuel-octane “floor” in the U.S.

“Higher octane fuels are the cheapest CO2 reduction on a well-to-wheels analysis,” Nicholson told panel moderator Brett Smith of CAR. “Fuels and engines must be designed as a total system. It makes absolutely no sense to have fuel out of the mix” of engine-technology discussions, he asserted.

Nicholson added that higher-octane, purpose-designed fuels “can be delivered very cost effectively.” A U.S. Dept. of Energy analysis proved the benefit of higher octane levels in improving combustion efficiency and reducing engine-out CO2, he said.

Honda’s Bienenfeld pointed out the benefits of higher fuel octane levels on advanced turbocharged engines operating under high-load conditions and in large-vehicle applications. He noted that boosted gas engines, hybrids and fuel-cell vehicles are on the future-development path at Honda. Nicholson touted the trend toward higher Otto cycle compression ratios and said his engineering teams are looking at Miller cycle combustion, in conjunction with turbocharging, “earning its way into the portfolio.”

Nicholson also said he’s bullish on diesels in the U.S., “which is one of the few growth markets” for compression-ignition engines, he stated.

Regarding 48-volt hybrids, Honda considers them to be cost effective “if the [current] standards stop at 2025,” Bienenfeld said.

EPA’s Grundler, speaking at MBS later in the day, noted that his agency is participating in the U.S. Dept. of Energy’s Optima project studying future fuels and has a working group focused on gasoline octane. “Fuel changes are not part of the TAR [Technology Assessment Report, part of the Mid-term Review of the current CAFE regulations],” he said, while suggesting that higher octane levels be considered for after 2025 “as long as increasing octane levels do not increase greenhouse-gas emissions.”

The Optima project aims at developing co-optimized fuels with a range of new engines for light-, medium-, and heavy vehicle use. Announced at the SAE High-Efficiency Engines Symposium by Dr. Wagner, Director of the Fuels, Engines, and Emissions Research Center at Oak Ridge National Laboratory, Optima is targeting a 30% reduction in petroleum consumption, per vehicle, compared with a projected 2030 base case that uses today’s fuels. The initiative is a collaboration with producers of gasoline and ethanol and the auto industry.

If Optima achieves its goal, it could reduce petroleum consumption by 4.5 billion barrels and save consumers up to $50 billion, according to the DoE.

Raising the U.S. octane “floor” will be essential for new combustion strategies currently in development for the 2020s including advanced Miller cycle and those combining lean-burn and stoichiometric operation aimed at achieving peak efficiency levels of 50%. and above. ORNL’s Dr. Wagner told the SAE audience that some multi-cylinder dyno engines have pushed beyond 55%.

Mazda’s Skyactiv program is progressing through G1, G2, and G3 development stages toward a marriage of Otto and Diesel cycle characteristics. Engineers’ target for the G3 is 18:1 compression ratio at lambda 2.5—a 40% improvement in thermal efficiency by setting the ideal pressure and temperature for homogeneous charge compression ignition (HCCI).

In Europe, the 102-RON (research octane number) “super premium” gasoline that’s widely available helps deliver a 10% increase in fuel efficiency for engines running compression ratios above 11.5:1, compared with engines running 9.0 to 9.5:1 using the 95-RON fuel that’s marketed as the mid-grade gas in Europe.

Author: Lindsay Brooke

Source: SAE Automotive Enginnering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分