Adgero混动系统采用了安装在牵引车和拖车内部的智能控制单元。

Adgero混动系统采用了安装在牵引车和拖车内部的智能控制单元。 Adgero半挂拖车驱动单元可在加速过程中参与车辆的运行,增强动力。

Adgero半挂拖车驱动单元可在加速过程中参与车辆的运行,增强动力。 Freightliner的SuperTruck概念车是一辆传统的柴油混合动力车,油耗为12mpg。

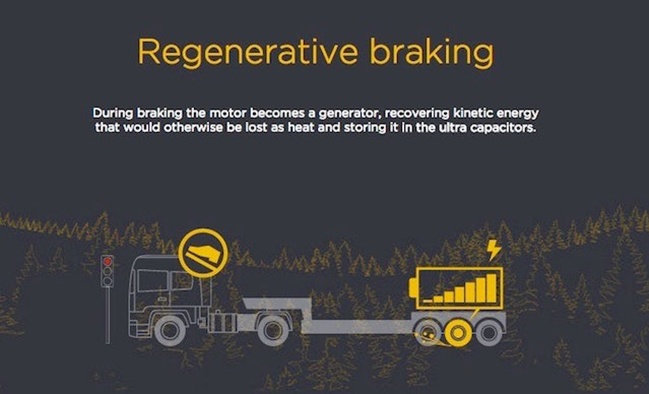

Freightliner的SuperTruck概念车是一辆传统的柴油混合动力车,油耗为12mpg。 Adgero系统可以将主要在刹车时消耗的能量进行部分回收。

Adgero系统可以将主要在刹车时消耗的能量进行部分回收。 Adgero的创始人与CEO Mack Murray表示,根据路面与交通情况,改装车可在燃油消耗量和排放水平方面减少15%到25%。

Adgero的创始人与CEO Mack Murray表示,根据路面与交通情况,改装车可在燃油消耗量和排放水平方面减少15%到25%。

欧洲委员会的估算和专业卡车期刊的测试数据显示,欧洲重型卡车的平均百公里油耗为31-38升(6-8mpg)。这个耗热率听起来很低,但是考虑到一辆大型卡车的重量可以高达40吨以上,情况就截然不同了。

卡车燃油主要有两个用途,一是克服极大的车重,使汽车加速至公路行驶速度,二是牵引卡车上坡。在欧洲的普通道路和高速公路上行驶的数百万辆重型卡车所造成的二氧化碳与柴油颗粒排放,占欧盟总排放量的五分之一。

满载的大型卡车重量极大,因此车辆在减速、下坡、频繁起停以及其他负载瞬变过程中所损失的能量,可以通过再生制动系统进行回收,从而提高燃油经济性并减少尾气排放。

位于法国斯特拉斯堡的初创企业Adgero正在研发一种混合式储能增压系统。它由一个动能回收系统(KERS)和一个电动驱动装置组成,可安装于半挂拖车的下方。公司称,Adgero混合系统(Adgero Hybrid System)将是针对重型卡车开发的第一个KERS。

根据路面和交通情况,这个改装系统可以节约15-25%的燃油与排放,公司创始人兼首席执行官Mack Murray表示。Adgero混合系统采用了爱沙尼亚Skeleton Technologies公司提供的800 V超级电容器组、一家欧洲著名加速辅助设备制造商生产的电动驱动桥、以及无线智能管理系统Adgero监控器(Adgero Monitor),该监控器可根据前方驾驶员的情况,产生输入信息,对后方车辆的再生制动与加速进行控制。

该系统正在申请专利。Murray表示,仅靠节省下来的能耗,就能使用户安装后3-4年内收回投资。如果能获得税务局的环境补贴,那么投资收回的时间还可进一步缩短。Adgero最近正在和一家欧洲著名的半挂拖车制造商协商,希望将该系统整合进他们的生产线内。

油电混合改装

“我们希望实施改装的目标客户,是经营半挂车车队的租赁公司和承租客户,尤其是那些拖车可单独运输的公路/铁路多式联运的运输系统,如Lohr、CargoBeamer或MegaSwing的系统,”他表示。只要是过去15年内生产的卡车拖车都可兼容。“因为拖车上没多少空间,所以我们只能将紧凑的储能与控制设备置入I型梁底盘下方。”

“最理想的是公路/铁路多式联运系统,” Murray解释,“比如说,来自挪威的鱼用卡车送往铁路储存站,接着用半挂拖车送往西班牙和其他地中海城市的仓库,卸货后装满水果再回到挪威。”

尽管大部分欧洲的重型卡车行驶线路都不到200 km(12.5英里),但是混合动力运输系统依然能节省燃油。英国、荷兰和德国是Adgero的首要目标市场,而法国的情况更加复杂一些。

Adgero团队认为,给拖车通电,比使用油电混合牵引车更合理,这是另一种回收柴油机能量的方法, Freightliner新推出的12mpg的SuperTruck概念车就采用了这种技术。“用一根600 V的缆线”将牵引车和被通电的拖车连起来,“然后你就可以像驾驶丰田普锐斯那样驾驶它。但这不是最好的方案,”他表示。使用普通的混动系统,需要位于铁路运输路段两端的拖车公司购置新卡车。“而我们可以提供同样的效果,而且不用购置新车。”

这个全新的捆绑式驱动单元包含一台200 kW电机,它的转速高达2900rpm,转速为零时最大扭矩可达750 牛·米 (550 lb·ft) ,并且已经通过了道路使用认证,使用年限可超过普通拖车的10年寿命。根据所使用悬架的不同,可使用电动驱动桥取代拖车架上的标准三桥架构(如LeciTrailer的curtainsider)中未受驱动的中央桥,因为该装置总是与地面接触。

Adgero保证,这个改装系统能够与现有的架构完全兼容。如果一辆没有监控器的卡车配上了装有Adgero系统的拖车,那么这个混合动力系统就会处于待机模式,其拖车也与普通的拖车并无区别。

Adgero是Murray在多年前与一些企业家共同创办的公司,他的合作伙伴包括首席技术官Ginès Linares、软件研发主管Soun Schuller和首席数据官Frédéric Soulier。

超电容器组的储能解决方案

“通过与Skeleton Technologies开展合作,我们将世界上最先进的超电容器组作为我们系统的核心,” Murray表示。“在以能量密度为关键衡量指标的卡车行业,这将给我们带来巨大的优势。” Skeleton使用一种获得专利的石墨烯材料,它具备更好的传导性能和更大的表面积,因此它的能量密度和功率密度分别可达到竞争产品的两倍和五倍。

“为了帮助Adgero实现他们的解决方案,” Skeleton首席技术官Volker Dudek表示,“我们专门研发了一种智能功率模块,通过一种获得专利的管理系统,对能量和功率进行智能监控,使其满足客户要求。”

去年,Skeleton的专家与Adgero团队合作,对一台原本在赛车上使用的800 V超电容器电源模块进行改造,使其符合道路运输车辆的需求。该模块由5个160 V的圆柱体蓄电池组构成,并可对每个电池单体进行监控,使其主动保持平衡。

Murray称,过去数月内Adgero混合系统经过了严格的振动、冲击和浸泡测试。2016年,法国物流公司Altrans还将对其进行道路测试。

Adgero和Skeleton Technologies打算逐渐增加产量,目标是在2020年前每年产量达到8000-10,000台。试生产期间(2016-2017年)的成本将为45,000欧元(50,600美元)左右,2018年,产品将以25,000欧元(28,000美元)的售价上市。尽管Adgero团队目前仅专注于欧洲的卡车市场,但Murray表示,这个技术概念也可能适用于北美和亚洲。

Murray还指出,Adgero的开放式电气总线和超电容器组可为改装车的行驶和其他车辆功能提供不间断的动力,比如4G网络、车载娱乐信息系统、车辆状态报告、用户可配置子系统,以及包括自动拖车跟踪、监控和控制、自动载荷监控、联合运输用的车队管理线路优化在内的网络数据服务等。

作者:Steven Ashley

来源:SAE《非公路用车杂志》

翻译:SAE 上海办公室

Fuel-saving KERS for big-rig trucks

The average European heavy-duty truck burns from 31 to 38 L of diesel fuel per 100 km of travel (6 to 8 mpg), according to European Commission estimates and truck magazine tests. That might sound like low fuel economy until one considers that a big-rig truck can weigh 40 ton (36 t) or more.

Accelerating such large masses to highways speeds and dragging them up hills account for a big chunk of the trucks’ overall fuel use. Road haulage by the millions of heavy trucks that ply European roads and highways accounts for more than a fifth of the European Union’s total output of carbon dioxide and diesel particulate emissions.

The great weight of fully laden big trucks, of course, provides an opportunity to recapture some of the energy that’s typically lost during deceleration, downhill travel, stop-and-go traffic, and other load transients using regenerative braking systems, which boost fuel economy and cut tailpipe emissions.

Adgero, a start-up firm that’s based in Strasbourg, France, is developing a parallel hybrid storage-boost system—essentially a kinetic energy recovery system (KERS) and an electric drive unit—that can be mounted under semi-trailers. The Adgero Hybrid System, it is claimed, is the first KERS for heavy-duty trucks.

Depending on the terrain and traffic conditions, the retrofit can save from 15% to 25% in fuel and associated emissions, said founder and CEO Mack Murray. The Adgero Hybrid System comprises an 800-V ultracapacitor bank supplied by Estonia’sSkeleton Technologies, an electric drive axle from a major European manufacturer for acceleration assistance, and the Adgero Monitor, a wireless intelligent management system that tracks driver input up front to control the regenerative braking and acceleration boost at the rear.

The patent-pending design can pay for itself in three or four years through reduced consumption alone, Murray maintained, and where expected tax climate subsidies become available the payback could be even quicker. The company has recently entered negotiations with a major European semi-trailer manufacturer to potentially integrate the new Adgero design into its production lines.

Electric-hybrid retrofit

“We want to retrofit semi-trailer fleets of lessors and leasing customers, particularly those that are used in road/rail intermodal systems in which the trailer travels alone as they do in Lohr, CargoBeamer, or MegaSwing systems,” he said. Any truck trailer made in the last 15 years is compatible. “There’s not much space on a trailer so we shoehorned” the compact energy storage and control add-ons into the I-beam chassis understructure.

“A perfect road/rail transport corridor for us,” Murray explained, “would be the shipping route by which Norwegian fish is trucked to rail depots where it is sent in detached semi-trailers down to Spain and other Mediterranean countries where they are trucked to warehouses that empty them of fish and fill them with fruit to be shipped back up to Norway.”

But even though the majority of European heavy-duty truck trips are less than 200 km (125 mi), the hybrid drive can save fuel. Great Britain, the Netherlands, and Germany are the company’s initial target markets, he noted, though France is more problematic.

The Adgero team thinks electrified trailers makes more sense than electric-hybrid tractors, an alternative way to recapture diesel fuel energy, one that is used, for example, by the Freightliner’s recent 12-mpg SuperTruck concept, which links tractor to powered trailer “with a 600-V line and so can operate like a Toyota Prius. It’s not the best solution,” he said. Conventional hybrid systems would require the hauling companies at both ends of the rail links to purchase new trucks. “We can do the same without the need for new trucks.”

The new strap-on drive unit, which contains a 200-kW motor capable of spinning up to 2900 rpm and providing a maximum torque of 750 N·m (550 lb·ft) at zero rpm, is certified for road use and has been engineered to exceed the typical 10-year lifetime of an average trailer. Depending on the suspension, he said, the electric-powered drive axle typically replaces the central undriven axle in a standard three-axle setup on the trailer rig (such as a LeciTrailer curtainsider), which is always in contact with the road surface.

The retrofit system is guaranteed to be fully compatible with existing infrastructure. And if an Adgero-enabled trailer is picked up by a truck with no monitor, the hybrid system simply stays in standby mode and acts like any other trailer.

Murray formed Adgero a couple of years ago together with fellow entrepreneurs co-founder and Chief Technology Officer Ginès Linares, Soun Schuller, the software development leader, and Frédéric Soulier, the chief data officer.

Ultracapacitor storage

“By partnering with Skeleton Technologies, we put the world’s most advanced ultracapacitors at the heart of our system,” Murray said. “This will give us an edge in an industry where energy density is a key metric.” He said that Skeleton uses a patented graphene material that offers better conductivity and higher surface area, and so can deliver twice the energy density and five times the power density of competitors’ products.

“To enable this solution for Adgero,” said Skeleton CTO Volker Dudek, “we developed intelligent power modules with a proprietary management system that allows for smart monitoring and control of the energy/power profile according to customer requirements.”

During the last year, Skeleton specialists worked with the Adgero team to adapt an 800-V ultracapacitor power module that is used in the motorsport industry to meet the needs of road freight vehicles. The module, which comprises five 160-V units that are composed of cylindrical cells, monitors each individual cell to actively balance itself.

In recent months the Adgero Hybrid System has been put through rigorous vibration, shock, and immersion testing procedures, Murray said. In 2016, plans are that the French logistics company Altrans will conduct road tests.

Adgero and Skeleton Technologies aim to ramp up production, with the objective of manufacturing 8000 to 10,000 units annually by 2020. Pre-series models (in 2016 to 2017) are to cost around €45,000 ($50,600), whereas series production models (in 2018) will be priced at €25,000 ($28,000). Although the Adgero team is concentrating on the European truck market, Murray said that the concept could probably work in North America and Asia as well.

Murray noted that the addition of Adgero’s open electrical bus and ultracapacitor bank to a trailer provides the retrofitted trucks with an uninterruptible power supply for services such as 4G, onboard telematics, vehicle-status reporting, and user configurable subsystems as well as network data services such as autonomous trailer tracking, monitoring and control, autonomous payload monitoring, and intermodal-compatible fleet-management route optimization.

Author: Steven Ashley

Source: SAE Off-Highway Engineering Online

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分