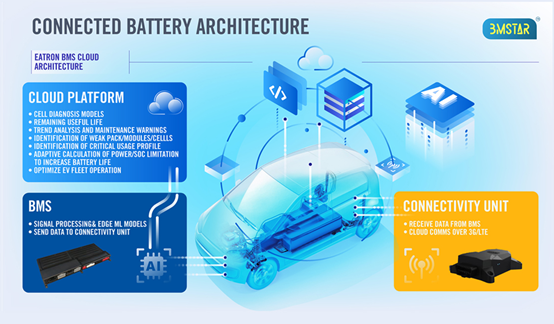

Eatron Technologies 基于云的网联电池架构。(图片来源:Eatron Technologies)

Eatron Technologies 基于云的网联电池架构。(图片来源:Eatron Technologies) Eatron Technologies 电池管理系统的 AI 电芯诊断。(图片来源:Eatron Technologies)

Eatron Technologies 电池管理系统的 AI 电芯诊断。(图片来源:Eatron Technologies) Eatron Technologies 公司高管(左起)Can Kurtulus、Umut Genc博士和 Amedeo Bianchimano 介绍了选择性 AI 技术的潜力。(图片来源:Eatron Technologies)

Eatron Technologies 公司高管(左起)Can Kurtulus、Umut Genc博士和 Amedeo Bianchimano 介绍了选择性 AI 技术的潜力。(图片来源:Eatron Technologies)

“我们认为这是一种借助选择性人工智能技术的基于物理建模的方法。” Genc 博士说,“对此,了解人工智能的局限性至关重要。首先,AI 系统有很高的内存和处理能力需求,这无疑会增加成本和能耗。其次,AI 技术的应用仍处于早期阶段,因此通常被认为并非万无一失。目前,任何完全依赖 AI 技术的关键功能系统都很难独立通过汽车行业的标准验证。”

在一家未公布名称的德国一级供应商以及英国和土耳其的工程团队的支持下,Eatron 开展了与汽车底盘管理系统和 SAE L2 级自动驾驶辅助系统相关的初始生产项目。不过,如今电池管理系统已经成为了Eatron 的重点研发项目之一。Eatron 声称,公司应用选择性 AI 技术的直接好处是无需再对电池进行过度管理,但同样可以保护电池耐用性,从而降低保修成本。

“目前,对电池寿命影响最大的因素是荷电状态变化窗口,也就是电池过冲和过放的极限,其次就是充电速率。” Kurtulus 表示,“正是如此,如今的大多数量产电池管理系统均经过专门校准,会坚决避免电池出现过冲或过放的情况,即使车辆几公里外就有充电站也无法多行驶一公里,并始终严格限制快充功能的使用,从而最大限度地避免发生保修索赔的情况。”

Genc 指出,将车辆的电池管理系统接入云可以让公司的选择性 AI 技术充分发挥其主要优势。“电池剩余使用寿命预测功能允许车辆 OEM 及时发布 OTA 校准更新,以最大限度地保护客户利益,例如放开快速充电和提升续航里程等,但同时有效控制保修索赔成本,保证电池的耐用性。”

举个例子,如今车主在购买二手车时很难确定车辆的电池剩余使用寿命。Genc 说,“在处理转让车辆时,能否查看并验证电池剩余使用寿命非常重要,特别是对于车队来说。我们可以在车辆仪表盘上增加显示电池的剩余使用寿命。” Eatron 的业务发展总监 Amedeo Bianchimano 补充说,“人工智能和云连接的结合可以让电池管理软件发挥更重要的作用,不仅可以最大限度地优化电动汽车的性能,还有助于提供主动保修管理等更多附加软件服务。”

按照 Eatron 的说法,车主还可以借助电池管理系统校准技术,享受到更长的续航里程和更快的充电速度,“并同时降低车辆临时故障抛锚的风险。”Genc 表示,“我们的方法是使用经过验证的基于模型的控制技术,创建一个稳健的系统,然后根据具体需求有针对性的应用人工智能技术。人工智能技术在电池健康管理中的应用只是一个起点,真正令人兴奋的是之后即将发生的事情!”

作者:Stuart Birch

来源:SAE《汽车工程》杂志

After two decades of significant advances in electric vehicle (EV) battery development, innovations continue to bring promises of greater battery performance, safety, faster charging, longevity and durability. One area of fresh thinking concerns battery management systems (BMS) using artificial intelligence (AI) as an enabler. Or more specifically, a novel dimension of AI, according to Dr. Umut Genc, managing director of Eatron Technologies, a U.K.-based company specializing in intelligent software for electric and autonomous vehicles.

“We define [it] as physics-based modeling with selective AI,” he said. “It is vital to understand AI’s limitations. First, the amount of memory and processing power required by an AI system is substantial, increasing cost and energy consumption. Second, AI is still in the early stages of application, so it is often seen to be not without risks. Any mission-critical system that is solely dependent on AI is currently difficult to validate to automotive standards,” Genc explained.

The solution, he noted, is the same for both challenges, starting with understanding the value that AI brings to objectives. Eatron’s technical director, Can Kurtulus, underlined the importance of OEMs recognizing that there will not be a huge step in battery chemistry for some time. Therefore, many improvements in durability, usable energy density and charging speed must come from improved battery management.

Kurtulus said he believes the key to be the application of physics-based software – control systems with embedded system models. This is a control technique in which look-up tables are replaced by an embedded software model of the system.

“In other areas of vehicle design, accurate digital simulations have helped to eliminate the need for over-engineering. This has brought down cost and weight in a ‘virtuous circle,’” he said. “Our approach to BMS is similar, except we will be embedding the model in the control system of every battery pack and applying it in real time throughout the vehicle’s life, not just during the design stage, so rather more than regular AI technology.”

First for EV diagnostics

With the backing of an unnamed German Tier 1 supplier and engineering teams in the U.K. and Turkey, Eatron’s initial production programs concerned chassis management systems and SAE Level 2 automated driver-assist systems. But BMS has now become a major R&D program. The immediate benefits claimed for Eatron’s selective AI applications are the reduced need to over-specify the battery to protect durability and hence lower warranty costs.

“The biggest influences on battery life are currently the state of charge window: how close to full charge and full discharge the battery is allowed to go, and then the rate of charge,” Kurtulus said. “So, in today’s production systems, warranty claims are minimized by calibrating the BMS to prevent the battery being charged to full capacity, to never approach deep discharge even if the vehicle is only a few miles from a charging station, and to always restrict the fast-charge capability.”

An Eatron innovation is to use its physics-based modeling techniques to predict the remaining useful life (RUL) of the battery. The company expects to be the first supplier of production technologies offering this feature for lithium-ion EV batteries. It also aims to be first to offer vehicle OEMs an opportunity to include a RUL indicator in the vehicle diagnostics.

Genc noted selective AI’s major benefits will be fully gained when the BMS is connected to the cloud. “Prediction of the RUL will allow the vehicle manufacturer to issue over-the-air calibration updates that maximize customer benefits, such as fast charging and range,” he noted, “while remaining confident that warranty and durability targets will be met.”

As more data is analyzed, the AI learns; predictions become more accurate and the benefits are automatically incorporated in the decision-making. There is also potential for the vehicle OEM to add new features that bring additional benefits for owners. For example, there is currently no way for a used vehicle buyer to determine the RUL of an EV’s battery.

“For fleets especially, an ability to manage and then validate the RUL will add significant value when they come to dispose of their vehicles. A dashboard RUL indicator could be fitted,” Genc stated. Added Eatron’s business development director, Amedeo Bianchimano: “The combination of AI and a connection to the cloud will give battery management software a much more important role, not just as a tool for maximizing e-vehicle attributes but also in offering warranty management and additional software services.”

More detailed prognostics

Eatron has established a joint research project with the U.K.’s Warwick Manufacturing Group (WMG), a department of The University of Warwick, to extend their BMS development into more detailed prognostics. At present, the system can only identify problems with battery cells as they occur (typically no more than a few seconds before failure), shutting down the battery pack or putting it into limp-home mode.

The objective of the research with WMG is to refine an innovation in diagnostics that allows Eatron to identify cell-related problems usefully before failure – not seconds before as is typically the situation today, but up to several months ahead of a failure.

“With this technology embedded in a battery pack, the chemistry can be driven much harder,” stressed Kurtulus. “This has been a goal for many years but previously it required considerable added hardware complexity. Our approach applies machine learning to established signal processing theory to isolate the diagnostic characteristic from the noise, without any additional components.”

For the vehicle owner, the benefits claimed by Eatron will also include BMS calibrations that deliver more range and faster charging, “while simultaneously reducing the risk of being left at the side of the road with a disabled vehicle,” Genc said. “Our approach is to create a robust system using proven model-based control technologies, then to carefully add in AI where it is needed for specific calculations. Battery health management is just the starting point. The real excitement is what comes next!”

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分