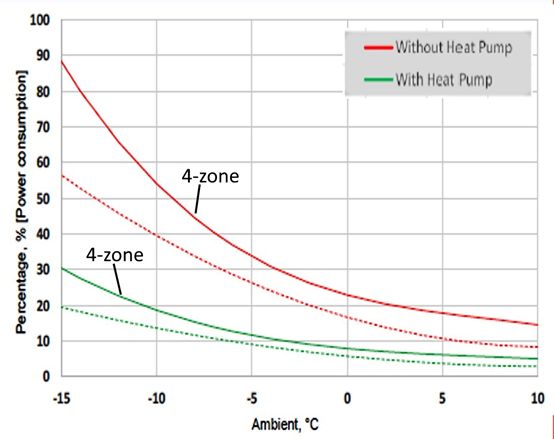

在Jaguar I-Pace中,该图表显示了热泵冷却操作的优势,包括四区和双区(下方的虚线)。

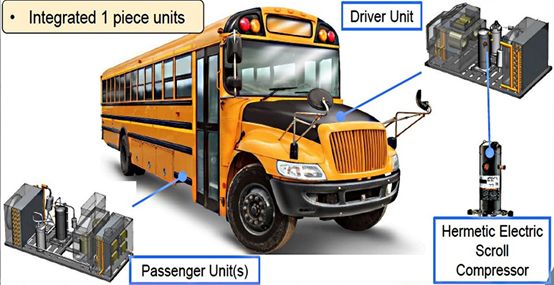

在Jaguar I-Pace中,该图表显示了热泵冷却操作的优势,包括四区和双区(下方的虚线)。 Emerson提出的电动校车将使用两个独立的热泵系统,全年为车厢提供舒适的环境。(ECT)

Emerson提出的电动校车将使用两个独立的热泵系统,全年为车厢提供舒适的环境。(ECT) 在3.5℉(零下15.8℃)的高性能测试中,Emerson图表显示校车热泵依然达到标准冷却需求。

在3.5℉(零下15.8℃)的高性能测试中,Emerson图表显示校车热泵依然达到标准冷却需求。

热泵让车辆的气候控制系统的成本上升了50%,但是捷豹最新车型和电动校车的应用案例表明,如果能改善设计,热泵产生的效益完全可以弥补这些额外成本。

气温低时,搭载了热泵的纯电动汽车是否能以合理的系统成本,既减少显著的能量损失,又保持座舱的舒适温暖呢?这个问题在2018年SAE热管理系统研讨会上引发了热烈讨论。尽管针对量产纯电动车型的有效解决方案尚未成型,但纯电动汽车的热管理已经取得了重大进步。

如果采用目前通行的热敏电阻(PTC)加热的方法,纯电动汽车的续航里程在冬季会缩水大约40%。对此,车企普遍表示不满。根据Hanon Systems在2017年所做的测试,按照50公里通勤距离和30分钟通勤时间算,如果座舱已经预热完毕,那么一个简易的制冷剂循环余热收集回路从电子元件、电机和电池包中采集的热量,对座舱制热而言已经足够了。

Hanon的研究表明,这种回路设计的经济效益和效率都远远高出热泵。尽管如此,随着续航里程更长的纯电动汽车进入市场,热泵还是会占有一席之地。尤其是对于将由柴油转为电力驱动的校车而言,热泵比制冷剂回路更为合适。

蒸气注入法

捷豹将于2019年推出的全新I-Pace四驱车型在瑞典阿尔耶普卢格的冬季测试中排名第一,该款车型搭载了一个90千瓦时的电池包,额定续航里程高达240分钟/384公里。和日产聆风相比,I-Pace着眼于高端市场,定价更加灵活。据称,该款纯电动车型在极寒天气下的续航里程几乎不会衰减,其采用的热泵系统也融入了多项创新设计。

作为此次SAE热管理研讨会的演讲嘉宾之一,捷豹路虎热管理工程师Nilabza Dutta在报告中指出,虽然I-Pace的HVAC系统增加了“30%-50%”的成本,但如果通过增大电池包的尺寸来弥补使用热敏电阻造成的续航里程损失,成本将上升150-450%,除此之外,电池的充电还将产生80%到300%的额外成本。

因此,捷豹I-Pace选用了热泵系统,并大力对其进行了优化。首先,HVAC的空气分配有三种模式:仅驾驶座、驾驶座加副驾、前排加后排。其次,还部署了吸收电子器件热量的制冷剂回路。为了实现最佳制热性能,I-Pace搭载了一个注气式HVAC热泵系统,不过该系统并不包含目前很多纯电动车型所采用的油门启动式再生制动系统。

去年,电装在普锐斯Prime插电式混合动力车型上引入了注气式热泵,其中包含一个液气分离器。这种从商用热泵系统中借鉴而来的设计,在低温条件下往压缩机里注入热蒸气产热,有效克服了热泵在气温低至0℃/32℉时因为制冷剂的质量流率降低而失效的问题。

丰田称,Prime的最低工作温度是14℉/-10℃。Dutta表示,搭载了吸热回路的I-Pace系统可以回收高达4.5 千瓦的能量。他在研讨会上指出,I-Pace的吸热回路的功率为0.3千瓦,在0℃(32℉)时,可以从电子器件和电机中分别收集2.5 千瓦和1.9千瓦的能量,净收益总共为3.8千瓦。当气温降到-8℃(18℉)时,制冷剂回路系统也可以收集3.5千瓦的能量。

Hanon的研究表明,捷豹I-Pace的座舱预热的作用已然十分显著。如果没有座舱预热,热泵系统只能节约17%的能量。有了座舱预热后,节能效果高达83%。就算关闭热泵,搭载了座舱预热的I-Pace依然能节约49%的能量。其续航里程效益更是令人惊叹:在零下10℃到0℃(14-32℉)的条件下可以增加30-45公里(18-27公里)。

此外,为了优化续航里程,I-Pace还具备电池控制模块的空中升级软件性能。升级软件和所有Alexa语音控制设备兼容,还能升级车载娱乐系统。

校车热泵项目

一年中最热的几个月,学校通常是在放暑假,因此校车座舱设计一般重点关注寒冷天气下的制热问题,制热部件一般放置在座椅、驾驶员和阶梯下方。在热能管理研讨会上,来自艾默生环境优化技术有限公司的Shawn Vehr表示,有些地区的校车的A/C装配率大约只有25%。

如果要在校车上部署制冷剂回路,那就要从车头绕到车尾,线路会拉得很长,这也是为什么很多校车没有安装A/C系统。不过,尽管以柴油驱动的校车仍占主导,很多汽车制造商也在着手研发电动校车。对此,Vehr提议采用四季通用的双电动密闭式注气热泵组件。

Vehr表示,根据台架测试结果,对于一辆搭载了600伏特、440千瓦时的电池包的电动客车而言,如果单独使用热敏电阻加热,续航里程会从原先的305英里/488公里降到177英里/283公里,而如果搭载了注气热泵系统,续航里程可以维持在230到257英里/368-411公里之间。

该热泵系统可以按照美国国家运输安全委员会(NTSB)的标准,把座舱的温度从0℉提高到68℉(-18℃到20℃)。根据NTSB的规定,热泵系统应该在30分钟内将环境温度从80℉加热到100℉(27℃到38℃),这比NTSB的降温标准宽松一些。

They add 50 percent to climate-system outlay, but improved designs indicate costs can be recovered, for Jags or an electric school bus.

Can a heat pump-equipped battery electric vehicle (BEV) overcome major energy losses for cabin heating comfort in cold ambient conditions –and at reasonable system cost? These questions were addressed at the 2018 SAE Thermal Management Systems Symposium, and although definitive answers may not all be production ready, promising work has been done.

The industry recognizes as unacceptable the BEV battery pack range losses of up to 40%+ from winter operation with PTC (positive temperature coefficient) heating, which is the conventional approach. Testing by Hanon Systems in 2017 showed simple, coolant-circulating waste heat-gleaning circuits from power electronics, electric motor and battery pack would produce sufficient thermal storage during a commute-length drive (50 km/30 mi) in a pre-conditioned cabin (as part of a battery pack charge).

The Hanon research indicated this approach is far more cost-effective and efficient than a heat pump. However, as BEVs with greater range enter the market, the heat pump comes back into play. It also is being considered for such other uses as school buses, now typically diesel-powered, but being evaluated for electrification.

Vapor-injection approach

Jaguar’s new 2019 I-Pace AWD model (top, winter testing in Arjeplog, Sweden) features a 90 kW·h battery pack and up-to-240-mi/384 km rated range. It’s a premium-market vehicle with more flexibility in its cost/pricing structure than a Nissan Leaf, for example. The electric Jag also is expected to deliver near its rated range in very cold weather. And although it includes a heat pump, there is much more to the system.

In his SAE TMSS presentation, Nilabza Dutta, a Jaguar Land Rover (JLR) thermal-management engineer, cited “30% to 50%” as the extra cost of the I-Pace’s HVAC system. However, he said, there would be added cost of 150-450% for covering the range shortfall of using PTC by increasing the size of the battery pack. There would be an additional cost over that of the battery pack: recharging it from the grid, which Dutta said was in the range of 80-300%.

The Jaguar approach, therefore, was “do whatever is necessary” within the alternative cost framework. First, the HVAC air distribution is three-zone: driver only, driver and a front passenger and both front and rear. Next, there is a heat-gleaning coolant circuit for the electronics. It is integrated with a vapor-injection HVAC heat pump system for maximum heating season performance. It does not cover the regenerative braking – a “one-pedal” control system that is based off the accelerator and similar to those used on various BEVs.

The vapor-injection heat-pump design, introduced on motor vehicles last year by Denso on the Prius Prime plug-in hybrid, incorporates a liquid-gas separator. This approach, adapted from commercial heat pump systems, injects the hot vapor into the compressor to produce system heat at low ambient temperatures. In this arrangement the heat pump, which normally is ineffective at 0°C/32°F because of the slowdown in refrigerant mass flow in low temperatures, remains operational.

Toyota cites 14° F/-10°C as the lower end for the Prime. The I-Pace system, with its integrated heat gleaning, can pull up to 4.5 kW, Dutta said. At 0°C (32° F), it can draw 2.5 kW from the electronics/motor system with a collection loss of 0.3 kW, for a net gain of 2.2; and 1.9 kW with a loss of 0.3, for a total of 3.8 kW, he told the TMSS session. Even at -8°C (18°F), the system can pull a total of 3.5 kW, he added.

The effect of cabin preconditioning, as demonstrated by the Hanon research, is enormous even for the Jaguar I-Pace. Without it, the heat pump saves only 17%; with it, the saving jumps to 83%. And even with the heat pump turned off, the preconditioned car saves 49%. Range extension on the I-Pace as equipped is an impressive 30-45 km (18-27 mi), in operation from minus 10 C to 0 C (14-32 F).

Additionally, the I-Pace has an over-the-air software update feature for the battery control module, to optimize range. It works with any Alexa voice communication device, and at this time also can update the infotainment system.

School bus heat pump project

Schools typically are closed for vacation during the hottest weather months, so bus cabin comfort typically focuses on heat in cold weather, with under-seat and driver/stairwell units. There are geographical exceptions, however, and A/C is used in perhaps 25% of school buses, according to a TMSS presentation by Shawn Vehr of Emerson Climate Technologies.

But the need for long refrigerant lines to the rear of the vehicle has been a deterrent to A/C installations. Although diesel-powered school buses are predominant, work is underway to develop electrically powered buses. Emerson’s proposal is for an all-electric bus using two electrically powered self-contained heat pump assemblies with vapor injection. This would permit year-round use.

According to Vehr, off-vehicle testing indicated a severe loss with PTC heating alone for an electric bus with a 600-volt, 440 kW·h battery pack, with a projected range of 305 mi/488 km diminishing to 177 mi/283 km. With a vapor-injected heat pump system, however, the range would be 230-257 mi/368-411 km, he said.

The heat pump was demonstrated to be capable of pulling cabin temperature from a cold soak at 0°F up to 68°F (-18°C to 20°C). It also would meet the NTSB (National Traffic Safety Bureau) standard for hot soak pulldown to 80°F from 100°F (27°C to 38°C) in 30 minutes, though falling slightly short of high- performance cooling standards.

Author: PAUL WEISSLER

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Paul Weissler

- 行业:汽车

- 主题:管理与产品开发制造质量、可靠性与耐久性车身/机身与架构