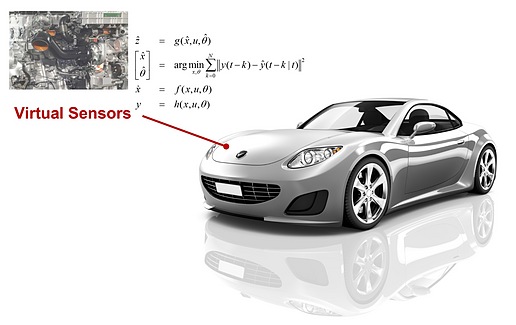

虚拟传感器是一种位于发动机ECU内部的计算机模型,它利用来自其他传感器和来源的数据,重建可代替真实传感器的数据。(霍尼韦尔)

虚拟传感器是一种位于发动机ECU内部的计算机模型,它利用来自其他传感器和来源的数据,重建可代替真实传感器的数据。(霍尼韦尔) 霍尼韦尔的汽车软件总经理Chris Greentree正在介绍,嵌在发动机ECU中的第一性原则模型如何实现虚拟传感器的快捷与精确。

霍尼韦尔的汽车软件总经理Chris Greentree正在介绍,嵌在发动机ECU中的第一性原则模型如何实现虚拟传感器的快捷与精确。

当今效率最高的发动机无一例外都是复杂的机器,无论是汽油发动机还是柴油发动机。它们的阀门正时、升力、直接燃油喷射、涡轮增压等性能都可以改变,而且废气循环系统(EGR)也多种多样。发动机结构必须足够复杂,才能平衡燃油经济性和排放控制。

为了控制一堆复杂的作动器,需要使用精确且反应灵敏的传感器。从进入歧管的整道气流到氮氧化物在排气中的含量,传感器必须测量各种数值。凭借着这些数据,发动机控制单元(ECU)就可以通过提前或延迟点火、控制阀门、调节涡轮增压器的气流等一系列操作,让发动机在保持最佳性能的同时将排气控制在限制范围内。

最大的挑战在于其复杂性与成本。工程师不仅要在一个制动器上操作十几个或更多的独立参数,而且增加设备本身也非常昂贵。测量氮氧化物或涡轮增压器速度的传感器可能需要花费一百美元以上(每台发动机),霍尼韦尔汽车软件总经理Chris Greentree表示。

但是,虚拟传感器为我们提供了另一种解决方案。用软件模型替代昂贵的硬件传感器,可让每台发动机的传感器成本变得微乎其微。

虚拟传感器与物理学

Greentree解释道:打个比方,为了创建一个虚拟的氮氧化物传感器,工程师们首先需要根据生产传感器和非生产传感器上采集到的数据对一个模型进行校验。这些数据包括气缸内压力和温度、空燃比、流经气缸的总气流量、湿度和背压等。接着将该模型进行简化,只使用生产传感器。“这些因素都会影响到排出发动机的氮氧化物的含量,所以如果我们的模型很正确,我们就能精确预测排出的氮氧化物含量,不再需要传感器。”

虚拟传感器这个理念的实施,似乎并不容易。有一种方法是使用实验室或测功器上测得的数据创建一个统计学的反应表面,这些数据是用实验设计(DOE)方法采集的。这些统计模型可以在不理解物理机制的情况下预测传感器的反应。但它们只能提供大概的预测,预测结果的准确性取决于采集数据的多少。

因此,霍尼韦尔用OnRAMP研发工具提出了一种替代方案。使用这个工具,工程师就能在ECU中嵌入一个第一性原理模型,随后再用它来创建虚拟传感器。

“这是一个基于物理学的发动机系统模型,” Greentree解释说,它的功能与工程师过去用于设计发动机的0D或1D系统模型很接近。“OnRAMP比传统的系统模型更简单,而运行速度却高出一大截。我们称它为‘中度保真的操控导向模型,’它可以让你在ECU中以接近原始状态的方式运行你的模型。”

他接着解释道,尽管该模型的计算足迹较小,但它依然需要运用理想气体定律、伯努利方程、质量与能量守恒定律等基础物理学知识。用户仍需使用DoE来收集数据,并校准模型,但OnRAMP及其所基于的物理控制策略,能够提供其他优势,那就是更好的控制模型和特定的虚拟传感器。在将模型载入ECU之前,OnRAMP的开发环境可将模型优化得更小、更快,但更精确。

虚拟优势

Greentree指出,霍尼韦尔的OnRAMP可使用虚拟传感器测定下列5种物质——排出发动机的氮氧化物、选择性催化还原过程中的氨、EGR流速、涡轮增压器速度,以及空气流速。除了极低的单位发动机成本外,虚拟传感器的另一项优势是比真是传感器运行更快,可用性更佳。

“(比方说),一个实体的氮氧化物传感器需要在发动机启动一段时间后,才能达到运作所需的温度。即便达到温度了,它的工作原理也注定了信号的传输会略微延迟,因此很难用在反馈控制中,”他解释道。

但OnRAMP则相反,该模型可以在氮氧化物离开发动机的那一刻预测其组成成分。“这种没有延迟的信息可以单独使用,也可以搭配实体传感器来提高控制效果,” Greentree表示。

“不仅如此,如果你的传感器用的越少,发生故障的可能性也越低,这也会省去一笔维修成本。”

Controlling engines with virtual sensors

The most efficient engines today, gasoline or diesel, are complex machines, with variable valve timing and lift, direct injection, turbocharging, and various flavors of exhaust gas recirculation (EGR). Engines need to be complex to balance the competing demands of fuel economy with emissions control.

Controlling the complex array of actuators requires precise, fast sensors that measure everything from mass airflow into the manifold to the engine-out level of NOx. With these data, the engine control unit (ECU) can advance or retard spark, actuate valves, and adjust turbocharger flow to get the engine humming at its optimum performance while keeping emissions within limits.

The challenges are complexity and cost. Not only do engineers have to manipulate a dozen or more independent parameters for individual actuators, but also adding more equipment is expensive. The cost of an individual sensor that measures NOx or turbocharger speed can run into a hundred dollars or more (per engine), according to Chris Greentree, General Manager Automotive Software for Honeywell.

Virtual sensors provide an alternative. They replace costly hardware sensors with software models that can cost very little per engine.

Virtual sensors and physics

As Greentree explains, for example, to create a virtual NOx sensor, they first calibrate a model using data from production and non-production sensors. These include in-cylinder pressure and temperature, air/fuel ratio, mass airflow through the cylinder, humidity, and backpressure sensors. Honeywell then simplifies the model to use only production sensors.

“All of these influence how much NOx will be produced, so if we model it correctly, we can accurately predict engine-out NOx and eliminate that sensor,” said Greentree.

The idea of virtual sensors is one that seems to be gaining traction. One way they are implemented is to use statistical response surfaces created from data measured in a lab or dyno, usually collected using Design of Experiments methods. These statistical models predict sensor responses without really knowing the physics. They are approximations only. Their utility is limited to how much data is collected.

Honeywell offers an alternative approach in its OnRAMP development tool. The tool allows engineers to embed a first-principles model in the ECU, using that to create virtual sensors.

“It is a physics-based model of the engine system,” explained Greentree, similar in function to familiar 0D or 1D system models engineers use to design engines. “The OnRAMP model is simpler than traditional system models and runs significantly faster than real time,” he explained. “We call it a ‘medium fidelity control oriented model,' allowing you to run your model native in the ECU.”

He went onto explain that, while it boasts a small computational footprint, it still incorporates basic physics such as the Ideal Gas Law, Bernoulli’s Equation, and Conservation of Mass & Energy. As he describes it, users still collect data using a DoE to calibrate the model, but the advantages of OnRAMP and its physics based control strategy is both a better control model and specific virtual sensors. Before loading it into the ECU, the OnRAMP development environment optimizes the model to create a smaller, faster running but still accurate model.

Virtual advantages

Honeywell’s OnRAMP enables five specific virtual sensors: engine-out NOx; selective catalytic reduction mid-bed ammonia; EGR flow rate; turbocharger speed; and fresh airflow rate. Another advantage besides very low per engine cost is that these virtual sensors respond faster and offer greater availability than real ones, according to Greentree.

“[For example], a physical NOx sensor takes some time after engine startup to reach a temperature sufficient for the sensor to function. Even after it has reached temperature, the operating principle of the sensor means that the signal will be slightly delayed, making it challenging to use in feedback control applications,” he explained.

In contrast, the OnRAMP model predicts the formation of NOx while it is leaving the engine. "This non-delayed information can be used on its own, or in conjunction with a physical sensor, to improve control," said Greentree.

“There are also less things to fail if you have fewer sensors, reducing possible warranty costs,” he said.

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Bruce Morey

- 行业:汽车

- 主题:噪声、振动与声振粗糙度动力与推进力质量、可靠性与耐久性工程设计与造型电气电子与航空电子测试与检验