B-52同温层堡垒轰炸机,预计使用寿命为90年。

B-52同温层堡垒轰炸机,预计使用寿命为90年。 B-52同温层堡垒轰炸机,预计使用寿命为90年。

B-52同温层堡垒轰炸机,预计使用寿命为90年。 电路板在回收之后,经常成为仿冒电子部件的“生产原料”。

电路板在回收之后,经常成为仿冒电子部件的“生产原料”。 即将被锯开的硅晶元。

即将被锯开的硅晶元。

如果一个仿冒的电子部件被安装在飞机、航天器或导弹等关键科技产品上,后果将不堪设想。这些设备或产品可能在需要运作时突然罢工,或在承受压力时崩溃。而更换仿冒电子部件的成本也是相当高昂,在2011年11月举办的参议院武装部队委员会(SASC)听证会上,美国导弹防御局针对美国国防部(DoD)供应链中的仿冒电子部件情况的报告中指出:更换THAAD导弹中疑似仿冒的存储设备的成本为270万美元。

2011年听证会及相关立法所带来的结果是,美国国防需要通过国防采办规定委员会对仿冒电子部件进行明确定义,并对国防部采购合同的其他一些要求做出规定。国防部对仿冒电子部件的定义如下:“被人为故意贴上错误的标签,给予错误的辨识信息的,非法或未经授权的复制品、替代品或变更品,或冒充原制造商生产的无更改的正品元器件产品,抑或冒充具备原制造商或当前设计机构(其中包括授权售后产品制造商)书面授权的无更改的电子部件正品。非法或未授权的替代行为包括:以旧充新,标注假冒的等级、序列号、批号、日期代码或性能特征等。”

行业企业与政府相关部门在制定SAE国际标准AS5553《假冒/仿冒电子部件的规避、检测、缓解与处置规定》时,提供了一个稍有不同的定义:“仿冒部件指那些被充当、认定或标记为正品部件的复制品、模仿品或替代品,以及由一个非法组织以误导、欺骗或进行诈骗为目的而修改的产品。”

只需看一眼仿冒电子部件的生产方式,人们就会对其进入全球供应链这个现状感到忧虑。传统的电子部件是由穿戴防护服的工人在气流、温度与湿度均受到严格控制的净室中,用高纯度单晶硅锭制作而成的。

而仿冒电子部件却不是用这样的原材料“制造”的,其材料取自从电脑、智能手机和笔记本电脑等废弃电子产品的线路板上拆除的电子部件。这些部件大多是在路边用焊铁从线路板上拆除,随后在河水或雨水中进行清洗分拣,最后按买家要求重新制作。有时候仿冒件也具备合法的货运标签,但却被放在弃置的工业卷筒上。

由于再造的标签很容易用丙酮擦除,因此早期的仿冒电子部件很容易检测出来。但随着人们防伪意识的增强,现在仿冒标签也升级到了可能需要物理测试才能分辨真伪的程度。

航空、航天与国防行业供应链的深度以及产品的使用年限要求,极有可能是仿冒电子部件进入供应链的原因。这三个行业的供应链很可能具有7-10个层级,而最低端的那些层级的供应商,根本不知道自己生产的产品会用于何处。

在2011年SASC的听证会上列举了几个仿冒电子部件进入供应链的案例。在一个案例中,一些分包商从一个同时从事电子产品回收与分销的公司中购买了晶体管。这些晶体管曾被当做电子废物出售,但现在又堂而皇之地“穿上”了原厂包装。

与那些使用一年就被换掉,或在新品上市后就可更换的手机和电脑不同,航空、航天与国防产品的设计寿命都很长。例如,B-52的预计服役寿命为90年,而自上世纪70年代末期开始服役的F-16根本没有标明使用终止日期。而许多电子部件从研发到生产,再到低价销售的周期可能仅为3年。当一个电子部件到达使用寿命(EOL)时,客户会收到通知,并有机会再次购买。

航空航天和国防行业共有三个采购渠道:原始部件生产商(OCM)、授权经销商(AD)或独立经销商(ID)。每种渠道都有各自的优势与劣势。OCM与AD可以提供生产商保修服务,但存货可能有限,特别是在寿命终止许多年后,很可能没有存货。而ID可能具备大量存货,但其保修服务并不完善。

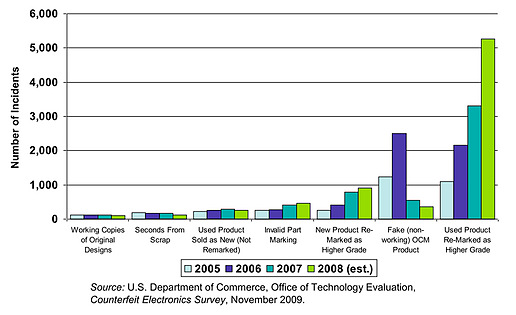

将仿冒电子部件赶出供应链的方法包括以下几种:进行立法、设立行业标准、发现仿冒电子部件时进行举报、生产时贴上防伪标签、公司在验收对每一个部件进行测试、对员工进行培训以避免采购仿冒部件、严守EOL期限并减少电子废品的产生等等。2010年美国工业与安全商务部发布的一份文件中列举了1300条行业与政府可以使用的具体措施。

上述方法都可被视为“目前的权宜之计”,那么未来有没有可行的新方法呢?美国国防部很可能会对发现使用仿冒品的分包商采取商削减预算的惩罚措施,迫使分包商确保使用真实产品。美国国防高级研究计划局将投资研发一种可以证明电子产品真实性的微小部件(尺寸约为100微米 x 100微米)。此外,国防部还将在所需电子部件的生产上更多地使用那些值得信任的厂家。最后,在修理维护时如果得出“无故障”的检测结果,很可能会进行更仔细的检查,因为这很可能是使用仿冒电子部件带来的结果。

只有整个供应链上所有层级,包括最低层级的供应商和到主机厂、政府部门等最终用户共同努力,才能杜绝仿冒电子部件进入供应链中。为达到这一目标,我们需要在生产工艺解决方案的改进、对使用仿冒电子部件行为的举报给予积极回应、鼓励举报、减少获取电子废品的机会等方面做出更多努力。

本文由SAEInternational出版文章《仿冒电子部件及其对供应链造成的影响》的作者Kirsten M. Koepsel专为《航空航天工程》撰写。Koepsel居住在华盛顿,为知识产权政策分析师。

Counterfeit electronic parts: Manufacture of and avoidance

If a counterfeit electronic part is installed in critical technology such as aircraft, spacecraft, or missiles, the consequences can be quite drastic. The equipment or the product could quit working or not work when needed or fail when put under stress. The cost to replace counterfeit electronic parts can be quite expensive as theMissile Defense Agency testified in November 2011 at the Senate Armed Services Committee (SASC) hearing on counterfeit electronic parts in the Department of Defense (DoD) supply chain: the cost to replace suspect counterfeit memory devices in the THAAD missiles was $2.7 million.

As a result of the 2011 hearing and related legislation, DoD through the Defense Acquisition Regulations Council was tasked to define what a counterfeit electronic part was along with other DoD contract requirements. DoD defines a counterfeit electronic part as: “An unlawful or unauthorized reproduction, substitution, or alteration that has been knowingly mismarked, misidentified, or otherwise misrepresented to be an authentic, unmodified electronic part from the original manufacturer, or a source with the express written authority of the original manufacturer or current design activity, including an authorized aftermarket manufacturer. Unlawful or unauthorized substitution includes used electronic parts represented as new, or the false identification of grade, serial number, lot number, date code, or performance characteristics.”

A slightly different definition was developed by industry and government participants during the drafting of the SAE International standard AS5553, Fraudulent/Counterfeit Electronic Parts; Avoidance, Detection, Mitigation, and Disposition: “A fraudulent part that has been confirmed to be a copy, imitation, or substitute that has been represented, identified, or marked as genuine, and/or altered by a source without legal right with intent to mislead, deceive, or defraud.”

A quick glance at how counterfeit electronic parts are manufactured leads one to be concerned about their entry into the global supply chain. Traditional electronic parts are manufactured from highly purified mono-crystalline silicon ingots in clean rooms with workers wearing “bunny suits” and controlled airflow, temperature, and humidity.

Counterfeit electronic parts are not “manufactured” from raw materials but from electronic parts removed from circuit boards found in discarded electronic waste (e-waste) such as recent model computers, smart phones, and laptops. The parts are removed from the circuit boards by using a soldering iron most likely on a sidewalk and subsequently cleaned in a river or rainwater before sorting and re-marking to the buyers' request. Sometimes the counterfeits will have legitimate shipping labels or placed on discarded industry reels.

Early counterfeit electronic parts were easily detected as the re-marking could be removed with an acetone wipe. As the awareness of counterfeits increased, the re-marking advanced to the stage where physical testing may now be required to tell the counterfeit electronic part from an authentic part.

The depth of the aviation, space and defense industries supply chains as well as the long life of the product most likely contribute to how counterfeit electronic parts can enter the supply chain. The supply chain of the three industries may be 7-10 tiers deep with the lowest tiers unaware of where their product will be used.

At the 2011 SASC hearing, several examples of how counterfeit electronic parts entered the supply chain were detailed. In one case, the subcontractors had purchased transistors from a company that was both an electronics recycling company and an electronics distributor. The transistors had previously been sold as e-scrap but appeared to be in their original packaging.

Aviation, spacecraft, and defense products are long-lived, unlike cell phones and computers that may be replaced every year or when the newest model comes out. The B-52, for example, has an expected service life of 90 years and the F-16, which has been flying since the late 1970’s, has no service termination date. Many electronic parts may have a life cycle of three years from introduction to production to low sales. When an electronic part reaches an end of life (EOL), customers will be notified so that they have an opportunity to make one last purchase.

The industries can purchase electronic parts from the original component manufacturer (OCM), an authorized distributor (AD), or an independent distributor (ID). Each of them have specific advantages and disadvantages. The OCM and AD will typically offer a manufacturers warranty but may have limited stock, particularly many years after the EOL. The ID may have large stocks but limited warranties.

Solutions to keeping counterfeit electronic parts out of the supply chain can include: legislation, industry standards, reporting of counterfeit electronic parts, authentication marking at the time of manufacturing, testing of every component received at a company, training of employees to avoid purchasing counterfeits, and reducing of e-waste by responsible EOL handling. A 2010 Department of CommerceBureau of Industry and Security publication ended up receiving over 1300 best practices that industry and government could use.

The above listed solutions could be considered “today’s solutions” but what future solutions can we envision? The DoD budget will most likely decline putting more pressure on contractors to ensure authentic parts are in their product. The Defense Advanced Research Projects Agency is investing in the development of small components (100 micron x 100 micron) that will authentic electronic components. DoD could increase the use of the trusted foundry to manufacture needed electronic parts. The “No Fault Found” aspect of repair and maintenance may need to be more fully examined as counterfeit electronic parts may be causing the problem.

Working to keep counterfeit electronic parts out of the supply chain will need all tiers of the supply chain, from the lowest tier to the end user such as a prime contractor or government agency or department to work together in crafting solutions, responding to reports and encouraging reporting of counterfeit electronic parts, and reducing access to electronic waste.

This article was written for Aerospace Engineering by Kirsten M. Koepsel, author of the SAE International book titled "Counterfeit Electronic Parts and Their Impact on Supply Chain." Koepsel is an Intellectual Property Policy Analyst based out of Washington, DC.

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分