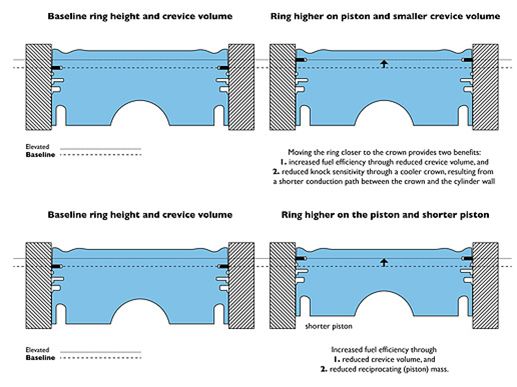

图中展示的是Materion全新活塞环技术的效果。该技术正在进行真实工况测试。(图例来源:Materion集团)

图中展示的是Materion全新活塞环技术的效果。该技术正在进行真实工况测试。(图例来源:Materion集团) David Krus说,他希望PerforMet环能首先登陆欧洲的OEM市场。(图片来源:Materion集团)

David Krus说,他希望PerforMet环能首先登陆欧洲的OEM市场。(图片来源:Materion集团)

为了实现每车平均碳排放不超过95克/公里的目标,以达到欧盟6d CO2排放标准,发动机制造商不断发出号召,希望供应商和专业研发公司能够给予他们技术支持。

专业材料研发公司Materion正在研究的就是这一问题。就已经透露的一些细节可知,Materion将通过实测研发一款新的硅金属强化铜合金,以增强压缩机活塞环的工效。这一技术被称为PerforMet,适用对象是小型增压发动机,使之同自然吸气式发动机相比,能够应对更加高温高压的作业环境。

Materion业务发展部总监David Krus指出,让更小的发动机输出和以往相同的动力和扭矩,同时也会对铝合金活塞用料产生磨损和疲劳等负面作用,影响耐用性。

“这会带来可靠性方面的问题。”Krus在接受SAE《汽车工程》杂志采访时谈到,“随着活塞顶部温度不断升高,早燃(敲缸)的可能性也会不断增加,影响发动机性能。”

Krus表示,在大大提升了导热性之后,PerforMet活塞环的研发已经取得了很大进展。他补充说,“这使得无效热量可以尽可能被带离活塞,导入发动机体和冷却套管。”

那么为何之前一直没有尝试这一技术呢?Krus解释说,这是因为Materion这一特殊合金无法直接浇筑成近净环形状(near-netring shapes)。同时,其他一些生产环状金属件的常用工艺,如异型钢丝,也很难应用到这一合金上。因此,这一想法只能等到相应技术成熟时,才能付诸实践。

英国技术咨询公司GE精密工程及当时公司的技术总监Scott Bredda参与了同Materion的合作。Bredda建议使用这一新的合金技术来加工热传导活塞环。

Krus解释说:“最初,我们的想法是用这一技术来加工阀门座和阀门导管。然后才产生了用其加工活塞环的想法。我们都觉得这主意实在太棒了!我们把它放到热学模型中(这一模型原本是用在Ultraboost项目上的,希望能在2.0升的I4增压发动机上实现5.0升V8发动机的性能),然后看到温度降低了很多。因此我们猜想这个方向应该是正确的,于是开始着手研发这一活塞环。”

据Materion称,合金活塞环的效能最高可达普通铁基活塞环的4倍,不仅活塞温度可以比以往最多降低25°C,活塞顶部温度也能最多降低30°C,既增强了活塞的抗疲劳能力,也提升了燃烧效能。

PerforMet成功问世后,发动机制造商也将有更多新的方案可供选择,其中就包括把活塞顶环的位置上移,以缩小活塞环和活塞顶之间的空腔,使积聚在未点燃部位的燃料有所减少,从而降低燃烧不充分而造成的尾气排放。

Materion宣布,PerforMet环已在内燃机汽车上进行实测,以了解其耐用性、使用寿命以及抗磨损等具体特性。同时公司还表示,有两家“全球性大型汽车制造商”正计划于今年晚些时候,在多汽缸发动机上测试PerforMet活塞环。

Krus说,Materion期待PerforMet环能率先进入欧洲市场,以帮助汽车厂商达到2020年法规要求。而要打入北美市场,则有可能要借助赛车赛事上的宣传推广。

To meet Euro 6d CO2 emissions targets calling for a fleet average emissions limit of 95g/km, engine OEMs increasingly are calling on suppliers and research specialists for technical help.

Materials development specialist Materion Corp. is doing just that, revealing details of a real-world test program to develop a new metal-silicide-strengthened bronze alloy for enhancing piston compression ring efficiency. The technology, called PerforMet, is aimed particularly at downsized, boosted engines that need to cope with higher pressures and temperatures compared to naturally-aspirated units.

David Krus, Materion’s Director of Business Development, noted that producing equivalent power and torque from smaller engines impacts wear and fatigue resistance characteristics of aluminum alloys used to make pistons.

"This raises reliability issues," he told Automotive Engineering, "and as the piston crown gets hotter, the tendency for premature combustion (knock) increases which affects performance.”

Krus said PerforMet piston rings have been developed having significantly improved thermal conductivity. “They allow unwanted heat to conduct effectively away from the pistons into the engine block and cooling jackets,” he added.

Why wasn’t it tried before? Krus explained that his company's unique alloy cannot be poured directly into near-net ring shapes. Nor is it particularly amenable to the other common process for manufacture of rings—using profiled steel wire. So the idea had to wait for new technology to allow it to be achieved.

Working with Materion was U.K. consultancy GE Precision Engineering and its then Technical Director Scott Bredda, who suggested using that technology for a conductive piston ring.

Explained Krus: “Originally, we had been looking at using the technology for valve seats and guides. Then came the piston ring idea and we said, ‘Great!’. We put it into our thermal model [from the Ultraboost project designed to achieve 5.0-L V8 performance from a boosted 2.0-L I4] and saw temperatures dropping very significantly. So we reckoned we were onto something good and are now developing the wire product."

The improvement is claimed by Materion to be up to four times greater than that of typical iron-based piston rings. This equates to average piston temperatures being reduced by up to 25°C and piston crown temperatures by up to 30ºC, increasing both fatigue resistance of the piston and its combustion efficiency.

The use of PerforMet has been designed to allow engine makers to introduce new solutions, including raising the piston top ring land to a higher location to reduce the cavity between the ring and the crown. Shrinking this crevice volume reduces the amount of fuel that gathers in the space that is not ignited, thus reducing emissions of unburned fuel.

Materion has announced that the PerforMet rings are now being evaluated in real-world ICEs for durability, longevity and wear characteristics. The company announced that two "high volume global car manufacturers" are planning to test PerforMet piston rings in multi-cylinder engines later this year.

Materion expects PerforMet to be used initially in the European market to meet the 2020 legislation. Its North American introduction is likely to be via racing, Krus said.

Author: Stuart Birch

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Stuart Birch

- 行业:汽车

- 主题:零部件