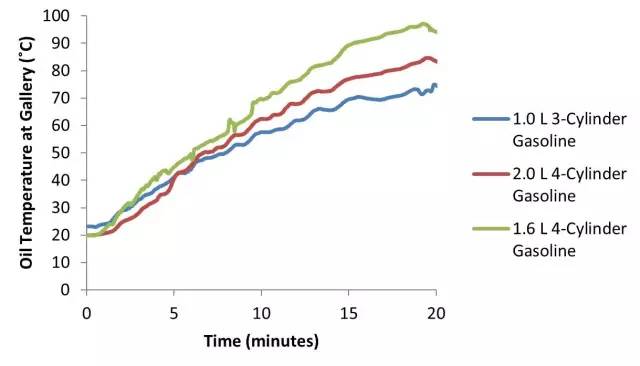

加热时间的重要性:图表显示了使用欧洲三大发动机进行模拟WLTP(全球统一的轻型车辆测试程序)周期测试结果

加热时间的重要性:图表显示了使用欧洲三大发动机进行模拟WLTP(全球统一的轻型车辆测试程序)周期测试结果 “通过电子控制油底壳内的机油量,根据外部需要的量来进行加热而不是全部。” Nexcel总工程师 Oliver Taylor表示。

“通过电子控制油底壳内的机油量,根据外部需要的量来进行加热而不是全部。” Nexcel总工程师 Oliver Taylor表示。 Nexcel润滑油模块已经成为阿斯顿·马丁的标配,同样的,这一概念也已经被运动到其他乘用车、轻型及重型卡车及设备之中。

Nexcel润滑油模块已经成为阿斯顿·马丁的标配,同样的,这一概念也已经被运动到其他乘用车、轻型及重型卡车及设备之中。 Nexcel机油模块被放置在发动机舱,更换一下仅需90秒。

Nexcel机油模块被放置在发动机舱,更换一下仅需90秒。 加热时间的重要性:图表显示了使用欧洲三大发动机进行模拟WLTP(全球统一的轻型车辆测试程序)周期测试结果

加热时间的重要性:图表显示了使用欧洲三大发动机进行模拟WLTP(全球统一的轻型车辆测试程序)周期测试结果

为了应对新的“真实世界”驾驶挑战,汽车厂商必须拿出新的发动机润滑系统,优化车辆发动机的性能,其中快速预热就是大家关注的重点之一。英国政府的一项近期调查显示,如今,英国民众开车出行的平均行程已经缩短至22分钟,大约在12公里左右,其中绝大部分均集中在市内区域。除了英国,世界其他地区民众的用车特点也呈现出类似趋势。很显然,由于行程本身相对较短,这就要求车辆必须实现快速预热,从而降低排放、提高燃料经济性、加快车舱制冷制热速度,并降低维护保养需求。

专家指出,事实上,机油加热时长对发动机预热的效果有很大影响。

“机油的真实热容其实远远高于其他发动机元件中使用的金属材料,很多人可能想象不到这一点。”嘉实多(BP Castrol)首席工程师Oliver Taylor表示,“减少3L机油(约2.6kg)的节能效果大约相当于车辆减重6.4 kg铝,或近12 kg的铁。这个角度来看,减少润滑油的用量明显可以加速发动机的预热。”

减少油底壳中的机油

在汽车冷启动阶段,发动机的内部摩擦很大,这是产生油耗和排放的主要原因,而且还会极大地拉低车辆在整个行程中的平均燃油经济性。Taylor解释说,在新的WLTP测试循环下,目前最常见的发动机可能不得不消耗相当比例(有时可能高达20%)的燃油,仅仅是为了对发动机的金属部分、冷却剂和机油进行加热。

为了适应如今大部分民众的用车特点,发动机必须保证启动阶段的机油量。此外,除了保证润滑系统内的机油(比如油道用量等)足量之外,油底壳内也必须保证有充足的润滑油,这样才能确保发动机在长时间的高速运转下可以充分排气,并达到延长机油换油期的目的。

此外,由于当今市场对发动机尺寸的要求越来越高,厂商不得不在机油中增加更多添加剂,从而提高小尺寸发动机的效率。很显然,机油成分越复杂,机油预热就必须迎接越多挑战。Taylor表示,添加剂可以“提高机油粘度、防止机油无限制稀释,但同时保证基础油不会过于粘稠。”他告诉《汽车工程》杂志,通过电子手段控制油底壳中的机油量,可以让发动机启动时无需再加热如此大量的机油。

嘉实多的测试表明,对于一款2.0L的高增压直喷汽油发动机而言,借助油底壳的机油喷洒来润滑曲轴系统,发动机油路中的机油用量最少可以减少2L,这可以有效降低车辆的寄生阻力或风阻,从而在大多数情况下降低车辆排放,并提高燃料经济性。

嘉实多表示,厂商可以选择将机油存放在Taylor口中一个位于发动机外的“智能容器”中,这有利于控制管理机油中的关键添加剂。Nexcel就是嘉实多推出的一种电子控制密封型机油存放解决方案。Taylor表示,Nexcel可通过一个对接系统安装在车辆的发动机舱内,整个过程非常简单,90秒内就能完成快速换油。

管理机油添加剂

Taylor坚称,由于可以解决车辆起步阶段的复杂热管理问题,未来这种独立的密封型可替换机油模块将获得更大的市场。此外,Taylor和他的同事还展示了一份2016年SAE技术论文中针对机油加热对CO2减排效果影响的调查结果(http://papers.sae.org/2016-01-0892/)。

Taylor解释说,Nexcel系统同时适用于干式或湿式润滑系统,该模块可保证发动机的机油量充足、满足上油需求,并同时确保模块内仍有机油剩余。Taylor表示,“这种作法可以大幅减少流动在润滑循环中的机油量,从而减轻发动机加热机油的负担。”

据Taylor介绍,机油中的添加剂可以维持机油的润滑效果,从而延长车辆换油期。目前常见机油中的添加剂成分大约占总重量的15%。然而,添加剂的高粘度会让基础油更加粘稠,这并不利于降低发动机摩擦。Taylor解释说,Nexcel模块可以帮助设计师“控制管理机油内的添加剂成分,允许每一部发动机都能用上经过专门调配的‘定制’机油”。

Taylor表示,“这样一来,我们就可以借助机油的定制化调整,更有针对性地降低发动机摩擦,这种作法非常有吸引力,而且成本很低。”

到目前为止,嘉实多公司仍对相关技术细节三缄其口,但Taylor表示,公司正在研发一种“基于全新化学成分”的新技术,可在换油间隔之间主动动态控制润滑油的质量。Taylor表示,“这些技术可以一起发挥作用,在整个机油使用期内保持润滑油成分的稳定。”他认为,未来的车辆发动机均将使用经过专门优化的定制机油配方,而嘉实多的努力可以让这一天尽早到来。

Taylor表示,“由于封闭系统的特点,Nexcel系统中的机油成分可以保持相对稳定的状态,从而保证发动机可以一直使用理想的机油,而这可以让发动机在轴承负载、最高工作温度或可靠性等方面发挥更大的潜力。”他说,“由于可以在机油的使用期内有效控制机油的质量,厂商其实可以利用这种有力工具,进一步发挥发动机的潜力,缩小发动机的尺寸,并提高发动机效率。”

该技术有利于机油回收利用

由于不同车辆使用的机油等级不同,回收的机油很有可能受到其他不同等级油品,甚至完全不同成分油品的污染,因此二手机油的收集和管理非常复杂,需要进行大量工作。嘉实多公司的可持续发展总监John Ward-Zinski表示,回收机油的二次精炼其实很难实现,因而大部分的回收机油会直接被当作燃料使用。然而这种作法有很大弊端,不仅效率低下,而且可能会给环境带来不利影响。

“在二次精炼之前,保证回收机油不受污染非常重要。”Ward-Zinski解释说,“英国石油公司的研究表明,42L原油仅能生产大约0.5L润滑油,但相同数量的回收机油,则可以提炼大约34L润滑油,不过这有一个前提,那就是必须避免回收过程中的交叉污染。”

Ward-Zinski表示,如果使用独立密封系统就完全没有这方面的问题,因为“在二次精炼之前,各类机油都仍分门别类地呆在各自的密封容器内。”

Optimizing engines for the new era of 'real-world' driving cycles will require new lubrication strategies—fast warm-up being a particular area of focus. A recent U.K. government survey showed that the average car journey time has fallen to only 22 minutes and average journey length to 12 km (7.5 m), most of it in urban areas. Such extreme duty cycles are increasingly typical in other global regions. They emphasize rapid warm-up for lowering emissions and fuel consumption, faster cabin heating and reduced maintenance.

The contribution to warm-up time due to heating the oil within the engine is often under-estimated, experts note.

“The specific thermal capacity of oil surprises many people because it’s substantially higher than for the metals used for the high-mass engine components," said Oliver Taylor, a chief engineer at BP Castrol. "Saving three liters (approximately 2.6 kg/5.7 lb) of oil is equivalent to shedding 6.4 kg (14 lb) from an aluminum block, or nearly 12 kg (26.5 lb) from an iron block. With that perspective, it becomes very clear how reducing the lubricant volume helps an engine to warm up more quickly.”

Less oil in the sump

High levels of internal friction during cold-start conditions are the dominant reason for increased fuel consumption and emissions during warm-up, which can comprise a significant proportion of the average journey. Taylor explained that in the new World Harmonized Light Vehicle Test Procedure (WLTP), up to 20% of the fuel energy is lost into warming up the metal parts, coolant and oil of a typical current-generation engine.

That engine’s oil volume throughout this period has to be sufficient to cater for the extremes required by a number of factors. In addition to that actually required for steady-state lubrication (i.e., the oil gallery requirement), the sump must contain sufficient lubricant to accommodate operation at a typical inclination of up to 30° from vertical to allow de-aeration when the engine is working at maximum speeds for prolonged periods and to achieve increasingly long oil-change intervals.

Another challenge comes from the increasingly complex lubricant additives required by today’s significantly downsized boosted engines. Additives "push up the viscosity, imposing a limit on viscosity reduction, however thin the base oil,” said Taylor. He told Automotive Engineering that electronic control of sump-oil volume can remove the need to always heat the full capacity required to accommodate the outer limits of these requirements.

BP Castrol testing shows that on a 2.0-L, highly-boosted, direct injection gasoline engine, more than two liters of oil can be removed from the engine lubrication circuit—effectively reducing the parasitic drag, or windage, that results from sump oil splashing on the cranktrain during operation. The reduction can significantly improve emissions and fuel consumption during most journeys.

Containing the oil within what Taylor terms an “intelligent cell” remote from the engine, also permits new approaches to the management of vital additives included within the oil formulation. One such approach is BP Castrol's self-contained, electronically managed sealed-cell system called Nexcel, is installed via a docking system (http://articles.sae.org/14426/) and can be swapped out within 90 s, according to Taylor, who led system development.

Governing the oil-additive content

The concept of a sealed-cell, easily changed engine oil module is increasingly viable within the complex issue of thermal management during warm-up, Taylor argues. He and colleagues presented results of an investigation into the effect of oil warm-up on CO2 emissions in a 2016 SAE Technical Paper (http://papers.sae.org/2016-01-0892/).

Nexcel has the capability to operate in a dry-sump architecture, but it can also be applied to a wet-sump installation, he explained. The system maintains sufficient oil in the engine’s oil pan to ensure adequate coverage of the oil pick-up, but retains the surplus within the cell. This "substantially reduces the thermal capacity of the oil circulating in the engine,” he said.

Contemporary engine oils contain up to 15% additives by weight, enabling them to remain effective for the extended oil-change intervals required by OEMs. But the additives' high viscosity contradicts the use of low-viscosity base stock to reduce engine friction. Taylor explained that the Nexcel unit "can be arranged to govern the additive system, allowing the engine to be supplied with oil containing 'tailored' additive content.

"That makes advanced oils a very attractive, low-cost route to reducing friction,” he said.

So far, BP Castrol is keeping secret details of the technique, but Taylor indicated that it is related to a new technology the company is developing based on "unique new chemistries” to actively control lubricant quality over the oil drain interval. “These techniques together will allow a precise and stable composition of the lubricant throughout the change interval,” claimed Taylor. He believes this is one of the major factors that will enable a significant further step towards highly optimized, vehicle-specific oils.

“Because the closed nature of the Nexcel system ensures the engine always receives the oil specified by engine designers, they can extend the envelope of possibilities in areas like bearing loads and temperatures while retaining robust durability margins," Taylor said. "Add the ability to manage oil quality through the change interval and you have a very powerful new tool for enabling new generations of downsized, highly-efficient engines.”

Oil-recycling benefit

The complexity and care needed to efficiently collect and manage the various oil grades drained from vehicles means that the vast majority of used oil becomes contaminated by other grades, or even by completely different fluids. This makes it impractical to re-refine, leading to a high proportion of recovered lubricants being used as fuel for burners that are “often of poor efficiency and questionable” environmental performance, noted BP Castrol Sustainability Director John Ward-Zinski.

“The benefit of controlling the feedstock for re-refining will be very significant," he explained, noting that just one-half liter of lubricant can be produced from 42 L of crude oil. BP’s research suggests 34 L of lubricant can be extracted from 42 L of recycled oil — "but only if you eliminate cross-contamination during the recycling process," Ward-Zinski said.

The sealed-cell system enables this "because it keeps individual oil types protected within their cells up to the point of re-refining.”

Author: Stuart Birch

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Stuart Birch

- 行业:汽车

- 主题:动力与推进力