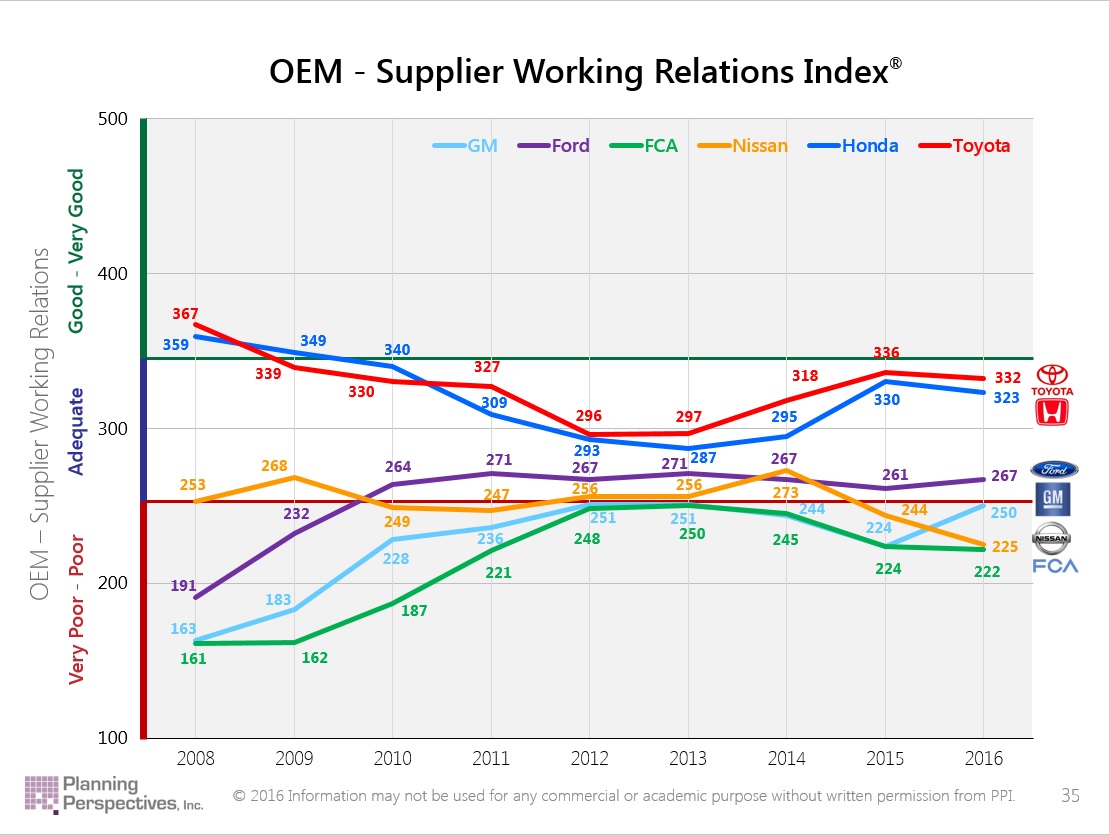

PPI公司的工作关系指数追踪了六家北美和日本汽车厂商与他们的供应商之间的关系。总体而言,丰田和本田的表现一如既往的优秀。不过,今年通用汽车的情况取得了显著改善,而日产的表现却急剧下降。

PPI公司的工作关系指数追踪了六家北美和日本汽车厂商与他们的供应商之间的关系。总体而言,丰田和本田的表现一如既往的优秀。不过,今年通用汽车的情况取得了显著改善,而日产的表现却急剧下降。

“汽车厂商一直面临的挑战非常简单:他们需要了解改进工作流程与改善工作关系之间的区别。但一些厂商就是不明白这个简单的道理,他们以为公司是在努力改善与供应商之间的工作关系,而事实上,他们只是在努力改进工作流程而已,”Planning Perspectives Inc.(PPI公司)总裁John Henke Jr.博士如是说。PPI公司坐落于密歇根州,主要研究厂商与供应商之间的关系。

今年5月16日,PPI公司发布了《2016年北美汽车OEM与一级供应商间的工作关系指数(WRI)报告》(PPI's 2016 North American Automotive OEM-Tier 1 Supplier Working Relations Index (WRI) Study),多家供应商在报告中评价了公司与世界六大汽车厂商,即菲亚特克莱斯勒汽车(Fiat Chrysler Automobile)、福特(Ford)、通用(General Motors)、本田(Honda)、日产(Nissan)与丰田(Toyota)的工作关系,并对这些公司进行了排序。据了解,一共有来自492家一级企业供应商的647位员工参与了2016年的报告调查,而这些供应商承包了这些汽车厂商(以上)年采购量的63%。

在这6家汽车厂商中,仅通用汽车较去年取得了显著提升,得分提高了26分。但这些改进仍不足以让通用公司进入WRI评分中“好 -非常好(Good – Very Good)”的级别。

“今年唯一的亮点是通用汽车。” Henke博士向《SAE汽车工程杂志》表示,“通用的进步非常明显,已经回到公司三年前的水平。”厂商如果能够保持与供应商的良好沟通,并对彼此的合作关系充满信任,则更容易获得一级供应商提供的创新解决方案。

OEM-供应商互信的好处

2016年是年度PPI发布该报告的第十六个年头,今年的报告显示,厂商与供应商需要建立稳固的工作关系,并保持开放、坦诚的沟通。这一点非常重要,因为原始设备厂商每年70〜80%的收入均用于向供应商采购零部件和材料。

Henke博士表示,2016年研究报告清楚说明了一点,“厂商及其工程团队如果能与供应商保持最佳工作关系,就能从供应商获得最好的服务和技术。”目前,Henke博士为密歇根州罗切斯特市奥克兰大学(Oakland University)的名誉教授,并在罗格斯大学(Rutgers University)供应链管理中心(Center for Supply Chain Management)担任研究员。

供应商更愿意与那些他们建立了互信协作关系的厂商分享最新的技术和创新。Henke博士表示,“他们甚至愿意在尚未敲定订单的情况下就分享这些信息。”

供应商在与工作关系最佳的厂商合作时,常常会拿出自己的最高水平。Henke博士说,“他们会为厂商提供最好,也最有实力的工程师,当然所有厂商都希望能与最好的团队合作。”

几十年来,丰田和本田一直都保持着与供应商间“专注于工程”的良好合作关系。

Henke博士表示,“本田和丰田的工程师在与他们的采购部门和供应商合作时的工作表现最好。优化厂商与供应商之间关系的因素有很多,包括公开和诚实的沟通、信任、与供应商合作以提高质量并降低成本的意愿,还要为供应商留下盈利空间,这些本田和丰田做的都不错。”

此外,由于丰田和本田在工程、采购和供应商方面存在“千丝万缕”的内在关联,因此这两家厂商在定价时也采用了合作的方法。

在采购和工程部门之间建立正面的合作关系极为重要。Henke博士解释说,“理想情况下,你肯定希望这两个部门能够通力合作,共同以最佳的价格实现最佳的解决方案。因此,这种合作的方法更加平衡,也更好。这样一来,所有人都将为此付出努力。”

作者:Kami Buchholz

来源:SAE《汽车工程》杂志

翻译:SAE 中国办公室

GM shines brightest in latest OEM-supplier relations study

“The continuing challenge facing automakers is very simple: They need to understand the difference between process improvement and work relations improvement. Some OEMs don’t understand this simple point. They think they’re working to improve relations when in fact, they’re working to improve business processes,” asserted Dr. John Henke Jr., President of Planning Perspectives Inc.(PPI). The Birmingham, MI-based company studies OEM-supplier relations.

In PPI's 2016 North American Automotive OEM-Tier 1 Supplier Working Relations Index (WRI) Study released May 16, suppliers evaluated and ranked their working relations with Fiat Chrysler Automobiles, Ford, GM, Honda, Nissan, and Toyota. The 2016 report findings were based on responses from 647 supplier personnel from 492 Tier One companies, representing 63% of the six OEMs' annual purchases.

Of those automakers, only GM notched significant improvement with a gain of 26 points from last year’s rankings. But GM’s improvement falls well short of being in the WRI’s Good-Very Good range.

“The only bright spot this year is GM," Dr. Henke told Automotive Engineering. "They improved significantly—back to the low Adequate status where [the company] was three years ago,” he noted. OEMs with good supplier communications and trusted working relations are apt to be offered novel solutions from the Tier Ones.

The benefits of OEM-supplier trust

Now in its 16th year, the annual PPI study shows the need for strong working relations and open, honest communications among automakers and suppliers. That point is underscored from a monetary perspective as OEMs typically spend 70- 80% of their revenue on the parts and materials provided by suppliers.

The 2016 study "shows clearly that OEMs and their engineering staffs with the best supplier relations are the benefactors of the best [services and technologies] suppliers have to offer,” said Dr. Henke, a professor emeritus of marketing atOakland University in Rochester, MI and a research fellow at The Center for Supply Chain Management at Rutgers University.

Suppliers are more willing to share new technology and innovations with those OEMs with whom they have the most trusted, collaborative relations. "And they will do so without the assurance of a purchase order,” Dr. Henke said.

Suppliers with the best OEM working relations often assign their top performers to a project. “They’ll give OEMs their best engineers to work with—the best and the brightest. And everyone wants to know they’re working with the best people,” Dr. Henke said.

For decades, Toyota and Honda have maintained a stellar engineering-focused supplier-relations reputation.

“Their engineers work best with their purchasing organizations and their suppliers. The key factors that affect working relations are practiced quite well with these two automakers: open and honest communication, trust, willingness to work with suppliers to improve quality and reduce cost, and being mindful that suppliers have to make a profit,” according to Dr. Henke.

Toyota and Honda also have the most collaborative approach to pricing, because of the close-knit internal relations at these two OEMs with engineering, purchasing, and suppliers.

A positive-focused working relationship between purchasing and engineering is exceedingly relevant. “Ideally, you want both functions working together to arrive at the best solution at the best price. This is a more balanced and better approach because inherently everyone is involved,” explained Dr. Henke.

Author:

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Kami Buchholz

- 行业:汽车

- 主题:管理与产品开发