诺德士表示,HCCI发动机的制造成本低于火花点火汽油机,公司无需对制造设施进行特别投资,就能实现最高30%的燃料经济性提升,以及接近于零的NOx排放。

诺德士表示,HCCI发动机的制造成本低于火花点火汽油机,公司无需对制造设施进行特别投资,就能实现最高30%的燃料经济性提升,以及接近于零的NOx排放。 这张剖面图展示了诺德士循环发动机的特征:一个顶部突起的活塞可以在向顶部靠近时,分隔出发动机的“初级”燃烧室。

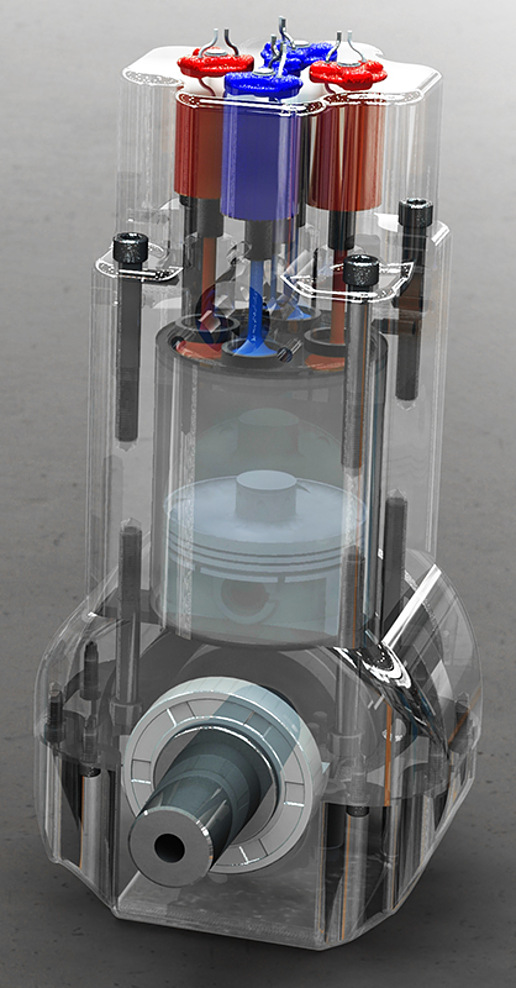

这张剖面图展示了诺德士循环发动机的特征:一个顶部突起的活塞可以在向顶部靠近时,分隔出发动机的“初级”燃烧室。

最近,美国诺德士(Nautilus Engineering)宣布,该公司的创新基础发动机设计,能够解决大多数长期困扰均质压燃(HCCI)发动机在汽车行业发展的固有缺陷问题,并通过SAE 2016全球汽车年会平台发布了旗下诺德士循环(Nautilus Cycle)发动机,并利用这个机会向多个行业介绍高效率、低排放的HCCI技术。

虽然诺德士曾在最近的媒体发布中表示,公司“相信目前拥有的专利技术足以将可控HCCI燃烧技术推广至多种发动机和应用之中,”但公司CEO兼首席研发科学家Matthew Riley表示,他在刚开始进行诺德士发动机研发时,并没有制定这么高的目标:“当时,我只是想改善一下割草机的发动机而已。”

据悉,低温HCCI燃烧技术可以保证为汽油发动机带来柴油机级别的高能效,而且无需担心柴油机的排放和成本问题,这仿佛是一座圣杯,不断激发着汽车动力系统研发人员的征服欲。但是经过十多年的研发,HCCI技术似乎是个无法实现的目标。研发人员不仅需要采用大量燃烧控制策略,有效解决冷启动的问题,还要保证发动机在整个转速范围内的正常运转,这些问题都阻碍了HCCI发动机在量产车型中的应用。

然而,诺德士表示,公司解决问题的途径并非不断叠加成本高昂的发动机软件控制。事实上,这款发动机采用了一款创新的活塞设计,这种活塞可以在工作时分隔出一个小型的“初级”燃烧室,在空气和燃油进入大型二次燃烧气缸进行可控的完全燃烧膨胀之前,先进行小规模的预混和“引燃”。此外,诺德士还在二冲程循环的进气口和出气口处应用了类似的措施,通过这一架构,实现对HCCI整个运行过程的简单控制。该技术的模拟示意视频如下。

“大家都想直接利用火花点火发动机,然后将其改造成HCCI发动机,” Riley在 SAE 2016 全球汽车年会上表示,“但这并不是一个好主意。”

诺德士在公司官网上表示,“由于采用了这种全新技术,我们得以在发动机的所有常规转速、负载和工作温度范围内,实现对HCCI循环的全面控制。这种技术可以快速应用至现有平台,达到甚至超过美国环保署的2025年排放目标的要求。”

关键在于小型燃烧室

在诺德士的设计中,空气和燃油可通过一个理想工作压强在160到200 psi之间的燃油喷嘴,在气缸外部的进气歧管中得到充分混合。诺德士发动机的小型初级燃烧室有几个可选的设计方案,可以实现(小型单气缸发动机的)固定压缩比,也可以将大型二次燃烧室的固定压缩比(大约10.5:1)提升1.5至2.5倍。发动机的进气口和出气口均采用了传统的提升阀,主要是通过数字液压(甚至电力)促动器驱动。这对阀门也能通过更加传统的凸轮轴组合进行控制。

诺德士提到,这款发动机的设计采用了单个止回阀,可以尽量减少典型二冲程发动机暴露在进气口和出气口蒸汽之中的情况。

根据设计,发动机的空气/燃油比完全是由发动机负载决定的,诺德士循环发动机运转时的空气/燃油比大约在24:1到31:1之间。至于这款发动机的NVH性能(噪声、振动和不平顺性),Riley坦诚地表示,“我们并不确定”。Riley似乎在示意,诺德士发动机的理想配置方式,可能会是一种水平对置气缸的布局。Riley认为,这种发动机在汽车应用中也有可能需要配置某种增压功能,以辅助气缸的填充和净化,特别是在诺德士循环发动机需要在米勒或阿特金森循环下工作的情况下。

Riley介绍道,这款原型发动机目前仅存在于计算机之中,尚未真正能够“跑”起来,其燃烧温度预计在1200华氏度左右。他表示,公司计划在未来8到10周内让发动机真正“跑”起来,并在未来6个月内打造一款“可以运转并且在功能上达到预期”的原型发动机。Riley认为,在大约为期1年的原型研发阶段之后,要继续将这种技术应用至“主流汽车应用”之中,还需要2到3年。

Drone Duty?

对比以往的情况,诺德士给出的时间表可以说是一反常态地谨慎,但公司CEO却非常信任这种发动机设计本身的吸引力:“可能这周就有人会来找我们签研发合同。”

Riley表示,对于立足于堪萨斯州的诺德士而言,公司目前的目标是与美国堪萨斯州立大学(Kansas State University)建立合作,共同研发一款适合无人机(UAV)使用的发动机。

Riley还表示,诺德士发动机也很容易进行传统四冲程循环。他坚信,这种设计的主要优势之一是尺寸灵活可控,因此可以轻松适应一系列的不同的交通运输设备的要求。

作者:Bill Visnic

来源:SAE《汽车工程》杂志

翻译:SAE 上海办公室

Nautilus claims radical advance in HCCI engine development

Claiming its novel base-engine design solves most of the intrinsic drawbacks that have slowed auto-industry development of homogenous-charge compression-ignition (HCCI) engines, Nautilus Engineering used the 2016 SAE World Congress to introduce its Nautilus Cycle engine, saying the unique platform offers an opportunity to introduce efficient, low-emissions HCCI technology to a variety of industries.

Although Nautilus said in a news release the company “believes it now holds patents to make controlled HCCI combustion possible for a wide range of engines and applications” company CEO and chief research scientist Matthew Riley said he started the Nautilus effort with a somewhat humbler horizon: “I just wanted to clean up lawn mower engines.”

Low-temperature HCCI combustion has been a lingering Holy Grail of automotive powertrain development, promising to impart on gasoline engines the efficiency of diesel—without diesel’s emissions and cost baggage. But a decade or more of serious development has proved HCCI an elusive target, its need for intensive combustion control, issues with cold-start operation and difficulty in addressing the entire automotive rpm range suppressing introduction for production-vehicle application.

Nautilus, however, said its approach to the issue was not to layer on yet more levels of costly engine software control. Instead the engine’s defining feature—a novel piston design that creates a small “primary” combustion chamber that propagates the air/fuel detonation to the larger secondary cylinder for full and controlled expansion—and an equally unique approach to dealing with the intake and exhaust paths of the two-stroke cycle create an architecture conducive to relatively simple control of full-range HCCI operation. Nautilus' video of the operation can be seen here.

“Everybody’s always tried to take a spark-ignition engine and make it HCCI,” Riley said at the 2016 SAE World Congress. “Bad idea.”

On its website, Nautilus said, “With this new technology, we've achieved full control over the HCCI cycle in all conventional rpm ranges, loads and temperatures. This may be rapidly implemented into existing platforms and will meet and even exceed 2025 EPA (emissions) regs.”

It's all about that small combustion chamber

Air and fuel are mixed outside the cylinder in the intake manifold via a fuel injector ideally operating at something approaching 160-200 psi. A couple of potential design options for the Nautilus engine’s small primary combustion chamber mean compression ratio could be fixed (say for small single-cylinder engines) or enable a variable compression ratio of perhaps 1.5 to 2.5 times the large secondary combustion chamber’s fixed compression ratio of somewhere around 10.5:1. Twin intake and exhaust ports are valved with conventional-looking poppets envisioned to be driven by digital hydraulic (or perhaps even electric) actuators. The valves also could be operated by a more conventional camshaft arrangement.

The engine design uses a single check valve, the company said, to minimize the typical two-stroke engine’s exposure of the intake and exhaust streams to engine lubricating oil.

The Nautilus Cycle engine will run air/fuel ratios approximately ranging from 24:1 to 31:1, as the engine design means the air/fuel ratio is determined strictly by engine load. As for a projected noise, vibration and harshness signature for the engine, “We’re not sure yet,” Riley admits. He seemed to indicate an ideal configuration for the Nautilus engine could be an opposed-cylinder “boxer” layout. And he would not rule out the likelihood that an automotive application might require some kind of supercharging to aid cylinder filling and scavenging—particularly if the Nautilus Cycle engine is adapted to operate under Miller or Atkinson cycles.

Riley said combustion temperatures are expected to be around 1,200º F for an engine that for the moment exists only in computer design: no running prototype yet exists. He said the company plans to have a running version in eight to ten weeks and a prototype engine “up and functional” within six months. After a year of prototype development, he sees a window of two to three years “for major streamlining of automotive applications.”

Drone Duty?

Given some past experiences, the timeline seems uncharacteristically cautious for a new-engine promoter—but the Nautilus Engineering CEO is openly bullish about the engine design’s intrinsic appeal: Somebody’s probably going to come to us by the end of the week with a development contract,” Riley predicted.

He said the immediate goal for Kansas-based Nautilus Engineering is to work with academic partner Kansas State university to develop a version of the engine suitable for an unmanned aerial vehicle (UAV) drone.

Riley also said the Nautilus engine also could easily run a conventional four-stroke cycle. One of its chief attributes, he insisted, is scalability to accompany its easy adaptability for a range of mobility applications.

Author: Bill Visnic

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Bill Visnic

- 行业:汽车

- 主题:动力与推进力