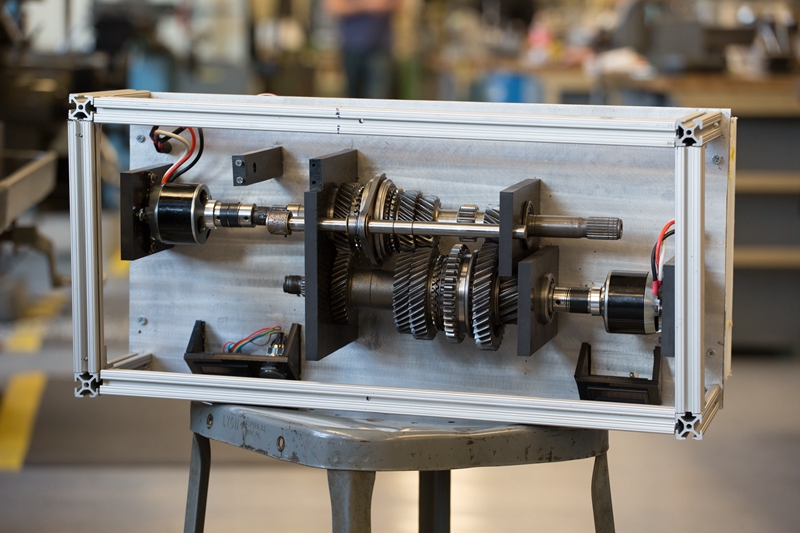

这一概念变速器展现出优良的速度匹配功能性,能够更好地配合无离合器式变速器的换档操作。(Lemelson-MIT项目图片)

这一概念变速器展现出优良的速度匹配功能性,能够更好地配合无离合器式变速器的换档操作。(Lemelson-MIT项目图片) Dan Dorsch和他的高性能车辆无离合器式变速器混合式传动系统。他在MIT完成的这个项目已衍生出多项发明,包括一个名为RoboClam的水底仿生挖掘装置,用于水底自动化机械的锚固。(Lemelson-MIT项目图片)

Dan Dorsch和他的高性能车辆无离合器式变速器混合式传动系统。他在MIT完成的这个项目已衍生出多项发明,包括一个名为RoboClam的水底仿生挖掘装置,用于水底自动化机械的锚固。(Lemelson-MIT项目图片)

美国麻省理工学院的一名学生发明家提出了无离合器式混合动力变速器的概念,目的在于提升车辆的节能表现,并保证车辆的高性能丝毫不受影响。

这个概念结构中运用到了一个电机来弥补在驾驶员在松开油门及离合器啮合期间的加速滞后的问题,而第二个电机则被用于在换档的同时进行快速齿轮匹配,因为整个过程中没有机械操作,所以提升了齿轮啮合的速度。

Dan Dorsch告诉《SAE汽车工程杂志》,“目前我们还处于概念验证阶段,将该项技术集成到目前的量产车中,还有许多工作需要完成。”

Dorsch 26岁,是一位二年级的博士生,也是美国麻省理工学院机械工程项目的国家科学基金会研究生奖学金计划研究员。这项发明为他赢得了2016年Lemelson-MIT“Drive it!”研究生奖的1万5千美元奖金。这项比赛由俄勒冈州波特兰市的莱莫森基金会(Lemelson Foundation)赞助,由MIT工程学院承办。

目前许多高性能量产车采用的都是双离合变速器,包括那些搭载了混合动力电动动力总成的车辆。比如,保时捷918 Spyder插电式混合动力车搭载的是7速PDK双离合变速器,而法拉利LaFerrari混动车配有一个7速双离合手自一体变速器。

许多创新型发明因为能够维持或提升车辆性能,并提高燃油经济性,迅速吸引了汽车行业工程管理人员的注意。IHS Automotive汽车公司的北美首席分析师Devin Lindsay表示,“燃油经济性法规对于高性能车辆而言,也具有重大影响。”

Dorsch还曾致力于汽车的轻量化设计工作。

“通过移除双离合变速器,包括离合器中填充的液体,可以实现车辆减重,”他说,“高性能车辆通常会搭载一个或两个电机,以满足性能要求,因此我们可以在传动系统中使用这些电机,并替代离合器发挥作用。”

Dorsch在MIT的研究导师和两个学生团队为项目研发工作提供了支持。他们打造了两个概念原型架构,每个架构从设计到制作工件用时约4个月。MathWorks矩阵实验室的模型展示了概念传动系统可能采用的运行方式。

Dorsch表示,“我们也分析了基于特殊传动配置的不同驾驶情景。”

这款概念变速器的测试阶段有可能会与一家欧洲的高性能车辆OEM合作完成,但Dorsch没有透露具体的厂商名称。他表示,“最早2017年就可以与这家OEM合作,进行原型概念变速器的实验室测试。”

Dorsch已为他设计的一款变速器申请了专利。他表示,在专利申请中记录了变速器整体架构、功能性,以及驾驶模式等信息。

在接下来的几个月中,他将为第二款设计申请专利。“第二款设计使用了一个单独的电机,而文中所提及的“专利申请中”的设计则使用了两个电机。”

作者:Kami Buchholz

来源:SAE《汽车工程》杂志

翻译:SAE上海办公室

Clutchless hybrid transmission concept for high-performance cars

An MIT student-inventor’s clutchless hybrid transmission concept aims to provide high-performance vehicles an energy-saving attitude without compromise.

The concept mechanism uses an electric motor to fill the acceleration lag that occurs when a driver releases the throttle and engages the clutch. A second electric motor is used for quickly speed-matching the gears during the shift since there is no mechanical means to speed up the next gear before engaging it.

“Right now, we are only at the proof of concept stage," Dan Dorsch told Automotive Engineering. "There is quite a bit of work left in order to develop the transmission into something that can be used on a production car.”

Dorsch, 26, is a second-year Ph.D candidate and a National Science FoundationGraduate Research Fellow in the mechanical engineering program at the Massachusetts Institute of Technology. His invention earned him $15,000 as the 2016 Lemelson-MIT “Drive it!” Graduate Student Prize winner. The competition is funded by Portland, OR-based The Lemelson Foundation and administered by MIT’s School of Engineering.

Many current high performance production cars rely on a dual-clutch transmission, including those with a hybrid-electric powertrain. Two current examples are the plug-in hybrid Porsche 918 Spyder with a 7-speed PDK dual clutch transmission, and the hybrid Ferrari LaFerrari with a 7-speed dual clutch automated manual.

Innovations that can maintain or improve vehicle performance and increase fuel economy quickly attract the attention of the industry's engineering management. According to Devin Lindsay, IHS Automotive’s Principal Analyst for North America Forecast, “Even high performance cars are not immune to fuel economy regulations.”

Weight reduction was one of Dorsch’s design bogies.

“The lightweight aspect is due to removing the double clutch, including the fluid that often fills the clutches,” he said. “And since high performance cars often have one to two motors for performance reasons, we can use the motor or motors in the powertrain to replace the function of the clutch.”

Dorsch’s MIT research advisor and two student teams assisted with the project’s development. Two concept prototype architectures were built, each lasting about four months from design to hardware. The MathWorks' MATLAB models show how the transmission is likely to perform.

“We have also analyzed different driving scenarios based on a specific powertrain configuration,” said Dorsch.

Transitioning the concept transmission to a testing phase is likely to unfold with a European high-performance vehicle OEM that he would not identify. Said Dorsch, “It’s possible that lab testing on a prototype concept transmission with this OEM could happen as early as 2017.”

Dorsch has filed a patent application on one of his transmission designs. He said the provisional patent describes the overall architecture, its functionality, and the driving modes.

A patent application will be filed in the coming months for the second design. “This design uses a single electric motor whereas the patent-pending design uses two electric motors,” he said.

Author: Kami Buchholz

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Kami Buchholz

- 行业:汽车

- 主题:动力与推进力