珀金斯公司旗下多款产品均已做好准备,可应对欧V法规。要应对新规定,面临挑战较大的主要是小型发动机,以及在欧IV/四阶段法规中并未涉及的设备。

珀金斯公司旗下多款产品均已做好准备,可应对欧V法规。要应对新规定,面临挑战较大的主要是小型发动机,以及在欧IV/四阶段法规中并未涉及的设备。 AVL公司可为发动机的研发提供基于型号的系统设计工具。凭借AVL在该领域的多年经验,这套工具可帮助发动机生产商达到欧V法规的要求。

AVL公司可为发动机的研发提供基于型号的系统设计工具。凭借AVL在该领域的多年经验,这套工具可帮助发动机生产商达到欧V法规的要求。

由于担心柴油排放物,特别是柴油排放物中的烟炱对民众健康的不利影响,欧盟委员会出台了欧V法规,将进一步对排放做出限制,并明确设定了限排值,也就是通常所说的PN值。按照新规定,对于输出功率在19 - 560 kW(25 - 750 hp)之间的发动机,PN值不得超过1x10¹²/kW·h。

咨询公司Integer Research的Fabricio Cardoso表示,除了以上规定外“欧V法规还扩大了适用于该规定的设备范围。”输出功率低于56 kW (75 hp)和高于560kW的发动机也必须接受管理。他表示,“欧五还将适用范围扩大至铁路、农业、采矿和建筑设备,以及欧IV规定并未做出限制的雪地摩托、ATV(全地形交通工具)和移动发电机等。”

Integer Research公司会记录选择催性化还原(SCR)设备中的化学合成尿素在世界各地的销售情况。这种物质经常被称为AdBlue或柴油尾气处理液(Diesel Exhaust Fliud),简称DEF。

“欧V法规的最大变化在于,设定了具体的限值。新规定的确是在不遗余力地推广DPF(柴油颗粒过滤器)设备,”AVL Powertrain Engineering公司首席工程师Mike Kenhard表示,“事实上,这项规定说的就是使用DPF设备。”

Kenhard表示,对于很多发动机厂商而言这是一个好消息,因为他们已经有了一些现成的DPF解决方案。他说,“对大多数厂商而言,欧V法规的执行,意味着他们需要应用这项技术,并从其他的既有产品中吸取经验,也有些厂商已经开始采用DPF技术了。

Kenhard表示,对于发动机生产商而言,要应对未来的欧V法规,面对挑战最大的是小型发动机。他指出,大马力发动机如果额外搭配后处理设备,可以提高价格以应对成本的上升,但提价对小型发动机来说通常行不通。他说,“功率在56-kW及以下的发动机将面对很大挑战。”

此外,现在生产商大多都希望产品能够出售到全球各地的不同市场。但由于各个地区的排放法规存在差异,厂商不得不针对不同市场推出不同的产品。

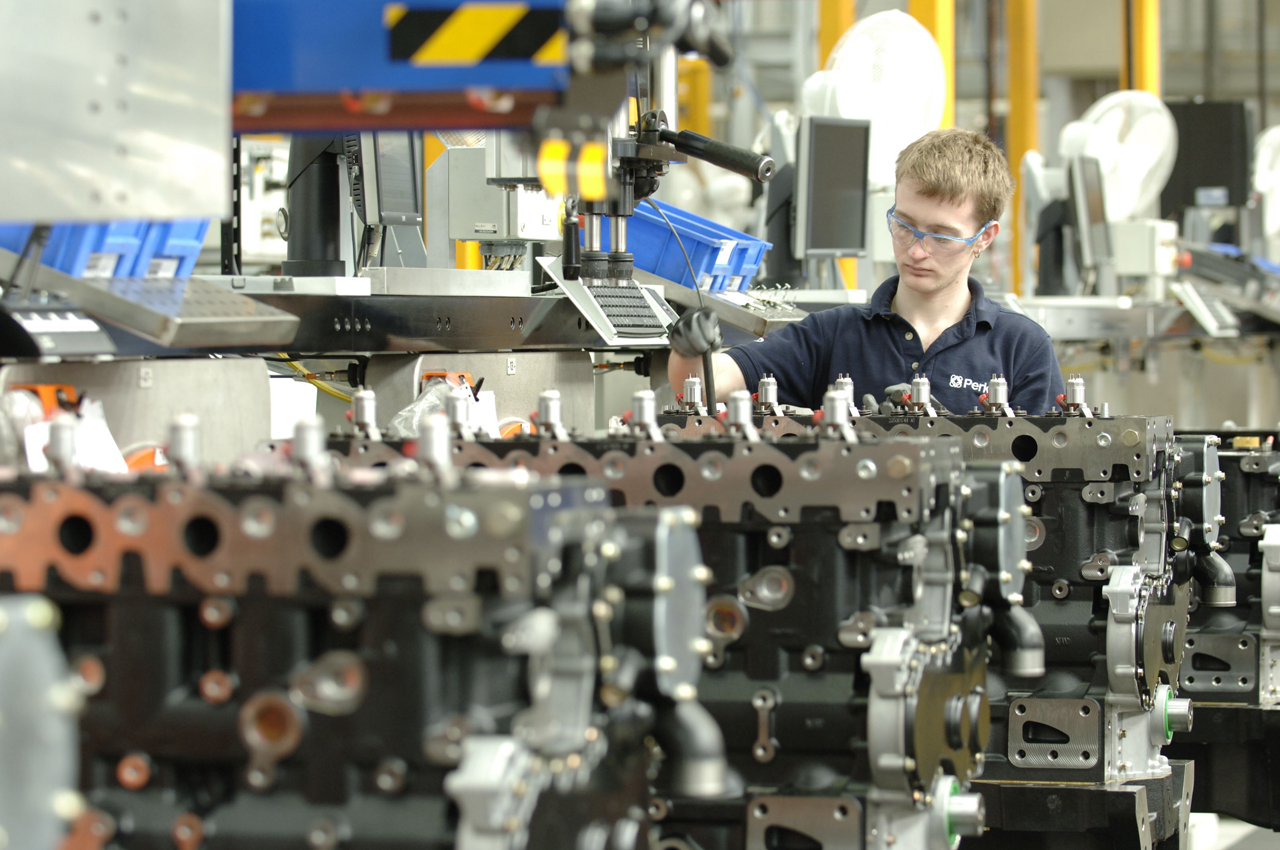

英国发动机生产商珀金斯(Perkins)的产品营销经理Oliver Lythgoe解释说,“当一个国家想为非公路设备发动机制定排放标准时,最简单的方法之一,就是借鉴一套现成的国际标准。”举例而言,一些国家可能会直接参考欧III A(三阶段)标准,而不是再去制定一套新标准。

其中,借鉴国际标准的关键在于,要结合自己所在地区的国情,符合配套基础设施的现状。“很多国家都想在减排上取得进展,但仅靠执行标准是不够的,市场中其他方面的发展也必须跟上,比如本地市场是否可以供应超低硫柴油,以及柴油机尾气处理液。”Lythgoe表示,“然而,随着各地排放控制相关配套设施的不断完善,我们预计在未来十年到二十年内,世界各地的排放标准将趋于一致。”

即使是应对当今相对宽松的欧IV(四阶段Final)法规,也并不容易,要控制功率较大的发动机排放污染,不采用后处理设备几乎是不可能的。Lythgoe表示,“对于部分功率超过56kW的大型发动机,我们几乎可以说,选择性催化还原技术是唯一可以助其实现NOx减排目标的可行方法,其他方法均会对设备的性能造成一定影响,这是不可接受的。”Lythgoe主张采用一种系统的方法应对这一问题。

Lythgoe表示,“对于功率输出在56 - 75 kW(75 - 100 hp)之间的发动机,厂商可以选择与铂金斯公司合作进行设备的整合。在很多情况下,通过这样的整合,都可以将发动机的功率需求降至56 kW之下,从而降低成本,并减少安装的复杂程度。”

作者:Bruce Morey

来源:SAE《非公路工程杂志》

翻译:SAE上海办公室

Stricter Stage V regs pose challenges

Worried about the adverse health effects of diesel exhaust in general, and diesel soot in particular, the European Commission’s new Stage V regulations will further reduce allowable limits on criteria emissions and place limit values on particulate number, often referred to as PN. For engines between 19 and 560 kW (25 to 750 hp), PN cannot exceed 1x10¹² per kW·h.

“Stage V also extends the range of machines required to comply,” said Fabricio Cardoso of Integer Research. Both smaller engines below 56 kW (75 hp) and larger engines above 560 kW would be regulated. “It also extends to new sets of railroad, agricultural, mining, and construction equipment as well as snowmobiles, ATVs, and mobile power generators that were not addressed in Stage IV,” he said.

Integer Research tracks, among other commodities, the worldwide sales of the chemical compound urea used in selective catalytic reduction (SCR) devices. This fluid is sometimes known as AdBlue as well as diesel exhaust fluid, or DEF.

“The big change with Stage V is the particulate number limits. It is really trying to encourage the use of DPFs [diesel particulate filters],” said Mike Kenhard, Chief Engineer for AVL Powertrain Engineering. “DPFs are the message behind the legislation.”

The good news for many engine providers, according to Kenhard, is that they already have those DPF solutions available. “For most people, implementing it means applying the technology and learning from other existing products or they already have it implemented,” he said.

The real challenges for engine makers in meeting a future Stage V is in the smaller engine categories, according to Kenhard. He noted that these typically do not command the price to justify additional aftertreatment equipment in the same way as larger horsepower engines. “56-kW engines and below is where it becomes very challenging,” he said.

Added to these challenges is the fact that OEMs today are interested in selling to multiple global markets. Increasingly fragmented emissions requirements are challenging them in offering a certified product for each market.

“When a country is considering introducing non-road engine emission standards, one of the simplest steps towards harmonization is for that country to adopt an existing globally recognized emission level,” explained Oliver Lythgoe, PerkinsProduct Marketing Manager. For example, a country may adopt a Stage IIIA/Tier 3 equivalent, rather than inventing their own.

The key to adopting such a standard is matching it to the supporting infrastructure that the country can provide. “While many countries want to make emissions improvements, progress can only be achieved at the same pace as other factors in the market such as the availability of good quality ultra-low sulphur diesel. Same with diesel exhaust fluid,” explained Lythgoe. “However, as appropriate emissions-related infrastructure continues to develop around the world, we could see global emissions standards move toward convergence over the next 10 to 20 years.”

Even meeting Stage IV/Tier 4F today requires careful consideration, and no foreseeable way of controlling pollutants without aftertreatment in the larger engines. “Above 56 kW, some form of selective catalytic reduction is really the only practical means of achieving NOx targets. Alternatives have been explored, but the effects on machine performance would not be acceptable,” said Lythgoe. He advocates a systems approach.

“One thing that OEMs can do for engines in the 56 to 75 kW (75 to 100 hp) range is to work with Perkins on machine integration. In many cases it will be possible to reduce the engine power requirement to below 56 kW, thus reducing machine cost and installation complexity,” said Lythgoe.

Author: Bruce Morey

Source: SAE Off-Highway Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Bruce Morey

- 行业:商用车

- 主题:动力与推进力