Aeristech公司的CEO Bryn Richards和eSupercharger。他表示公司所有的电机技术可以在1秒内充分满足发动机的气动力负荷需求,而不会引起常规发动机经常出现的冷却问题。

Aeristech公司的CEO Bryn Richards和eSupercharger。他表示公司所有的电机技术可以在1秒内充分满足发动机的气动力负荷需求,而不会引起常规发动机经常出现的冷却问题。 Aeristech的电机采用了永磁技术,响应速度更快,而不会引起开关磁阻电机经常出现的冷却问题。电机策略可以分隔换流和功率控制。

Aeristech的电机采用了永磁技术,响应速度更快,而不会引起开关磁阻电机经常出现的冷却问题。电机策略可以分隔换流和功率控制。 Mahle用一款3缸1.2 L发动机演示了eSupercharger。

Mahle用一款3缸1.2 L发动机演示了eSupercharger。

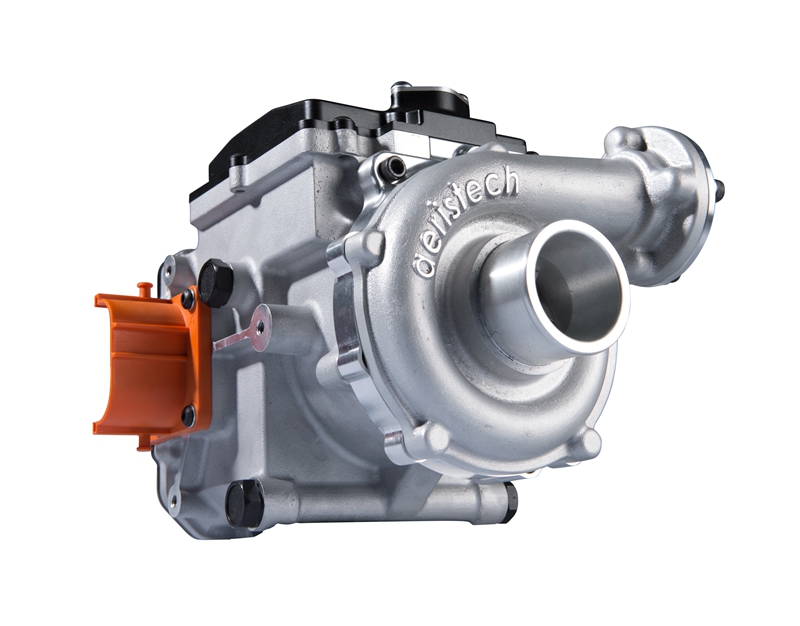

英国的Aeristech公司高调宣称已研制出“世界上功率密度最大的可变速电机”,有助于解决小尺寸发动机的技术难题,更好地实现二氧化碳减排目标。

公司CEO Bryn Richards表示:“对于极小尺寸发动机而言,多级或机械增压均不能解决问题,因为这些增压设备不能保证在低速时提供充足动力。下一代的小尺寸发动机需要电动增压器,功率充足,可以满足低转速时的发动机增压需求,并且冷却性能优良,可以实现持续运转。”

因此,Aeristech研发出了eSupercharger,旨在提供低速扭矩和即时节气门响应性能,消费者期望获得这些优良性能,但在小尺寸和“正常尺寸”的涡轮增压发动机中却难以实现。

Richards解释说,多级涡轮增压整合了不同尺寸的涡轮,有利于小尺寸发动机在更大的速度范围内驱动,但也带来了诸如成本、复杂度、热管理和催化性能方面的其他问题。他也强调,随着尾气排放限制日益严苛,催化性能带来的问题很可能会越来越严重。他表示:“对于一部安装在发动机和催化装置间的两级涡轮增压系统来说,其热质量会增加车辆在轻负载或发动机低速运行时的熄火概率。”

显然,替代方案是使用增压器,但常规的机械增压机无法在发动机低速运行时提供充足助力。Richards认为,电驱动单元“目前仅能提供最短暂的瞬时助力”。

依据目前的发展情形,Richards认为,汽车行业很有可能会大力发展48V系统,并打造出在低速时也能提供充足助力的电涡轮增压器。

“要实现持续工作,首先必须要满足冷却性能的要求,”他告诉SAE《汽车工程杂志》,并指出Aeristech所有的电机技术可在1秒内充分满足发动机的气动力负荷需求,而不会引起常规发动机经常出现的冷却问题。

新电机控制策略

目前,整个行业正在大力发展备受期待的48 V轻混合系统,可以为电动增压器提供所需功率,以保证小尺寸发动机在低速运行时提供充足的助力需求。同时,机械涡轮性能也得以优化,可以只在发动机高速运行时提供助力,可以实现更大的比功率和更低的排气阻力。

Richards解释道,为了充分发挥48 V系统的优势,提供电动增压,Aeristech公司采用了永磁技术。这种技术的响应速度更快,并且不会引起传统开关磁阻(SR)电机经常出现的冷却问题。目前,Aeristech公司已获得永磁技术专利。Richards认为,永磁技术是SR电机唯一的可选择的解决方案。他预计,一旦SR电机实现大规模量产,这两套系统的成本将基本持平。

“我们的电机控制策略可以分隔换流和功率控制,也就是说,电转换频率无需高于运转速度,”他说。“这种全新的方法可以大幅削减许多关键的开关元件的成本,并保证精准的高瞬时速度控制。”

这种方法也将赋予永磁技术很高的性价比,他表示,“这也是eSupercharger首次能够实现持续提供2.5bar及更高的助力”

该技术同时适用于柴油和汽油发动机。“在日益严苛的法规面前,现在柴油发动机依赖于过滤系统来处理废气中的颗粒物,但却增加了发动机的压力,”Richards指出。“如果能将这些颗粒物在内燃舱中转化为能量,而不是直接过滤出去,肯定更有意义。通过eSupercharger的运用,可以在发动机低速运行时及时响应瞬时变化,供应燃烧所需当量的气体,这样即可以解决排放问题,也一并提高燃油经济性。”

BMEP的显著收益

Aeristech表示,eSupercharger具备行业领先的功率密度和低惯性水平,可以在0.4秒内,以怠速到目标速度(idle-to-target speed)的瞬时响应性能,加速至150,000 rpm。该技术已成功通过里卡多公司(Ricardo)和英国马勒动力总成公司(Mahle Powertrain)的独立评估。

Richards表示,Ricardo曾使用其公司的WAVE模拟软件,为一款采用单极涡轮增压机、输出功率为221 kW的2.0 L汽油发动机建立详细的模型。他说,加装48 V的Aeristech eSupercharger能将涡轮尺寸提高80%,“可以在发动机的整个速度范围内提升BSFC(汽车制动油耗率),扭矩响应和瞬时响应。”

Ricardo最后表示,如果依赖于常规的单级涡轮增压机,而不使用eSupercharger,那么仅有大型发动机才能满足需求。Mahle用一辆D级别评估用车展示了48 V的eSupercharger,该车配置了公司生产的小尺寸1.2 L三缸汽油发动机。这款车原本配置的是两级涡轮增压机,发动机输出功率为144 kW(193 hp),BMEP(制动平均有效压力)刚刚超过30 bar。

Richards表示,“如果用eSupercharger替代小涡轮,大涡轮就可以实现再次优化,发动机的最大输出功率可达193 kW,2000 rpm时的峰值BMEP可达33 bar,这是非常了不起的。”他表示,在发动机的整个速度范围内,扭矩都有所提升,最大可达313 N·m (231 lb·ft);发动机在1200 rpm时的BMEP从20 bar提升至接近29 bar。

“Mahle表示,采用了eSupercharger后,单位气缸容量扭矩要高于市面上任一量产发动机,”Richards说。eSupercharger可以直接提高扭矩,并间接提高输出功率。通过用eSupercharger替换两级涡轮增压机中的小涡轮,Mahle的工程师可以加大主涡轮的尺寸,实现优良的操控性能和瞬态反应性能。

Richards预测,在未来,对于旨在达到95g/km的二氧化碳排放要求的C级车而言,其发动机将进一步减小尺寸,甚至会小于现有产品的最小尺寸。他表示,采用eSupercharger的高增压800cc的发动机可以提供与常规的2.2 L自然吸气发动机相当的功率和扭矩,“并提供同样高效的油门响应,而油耗却更低。”

作者:Stuart Birch

来源:SAE《汽车工程杂志》

翻译:SAE上海办公室

Power struggle produces eSupercharger

With the bold claim of inventing the “world’s most power-dense variable speed electric motor,” U.K. specialist company Aeristech believes it can help solve a significant challenge facing the use of downsized engines in pursuit of low CO2 emissions.

Said CEO Bryn Richards: “For extreme engine downsizing neither multi-stage nor mechanical superchargers are the answer, as an engine using them would lack power at low speeds. To support the next generation of downsized engines requires an electric supercharger with enough power to supply all the low speed boosting needs of the engine combined with sufficiently effective cooling to enable continuous operation."

Thus the development of the Aeristech eSupercharger, designed to provide the low-speed torque and instant throttle response that customers expect but can be challenging to achieve in turbocharged downsized and "right-sized" engines.

Richards explains that multi-stage turbocharging, combining large and small turbos, makes downsized engines easier to drive across a wider speed range, but introduces other issues such as cost, complexity, thermal management, and catalyst performance. The latter, he noted, is likely to be of growing significance as tailpipe emissions are further restricted: "The thermal mass of a two-stage turbocharger system located between the engine and the catalyst makes light-off more difficult to maintain during periods of light load or low engine speed,” he explained.

The obvious alternative is to use a supercharger, but conventional mechanical superchargers don’t deliver at very low engine speeds. And Richards believes that electrically-driven units “have so far only been able to provide the briefest transient boost."

He regards the achievement of a satisfactory electric supercharger with sufficient power to meet, convincingly, all low speed boosting needs could be achieved by the industry’s present likely move towards 48-V systems.

“As for meeting cooling capability requirements, that would be a must for continuous operation," he told Automotive Engineering, pointing out that Aeristech's proprietary electric motor technology delivers the full load air requirements of the engine in under 1 s without the cooling issues associated with conventional motors.

New motor-control strategy

The much-anticipated move towards mild hybrids with 48-V architecture would provide the power necessary for an electric supercharger to deliver the boost levels required by a downsized engine in the lower half of its speed range. With this arrangement, the mechanical turbo could be optimized purely for higher speeds, allowing greater specific power and less exhaust restriction.

Richards explained that to unlock the potential of 48-V systems to provide electric supercharging, Aeristech uses permanent magnet technology, providing a faster response without the cooling challenges arising from the alternative switched reluctance (SR) motors. He believes that SR motors are the only alternative to Aeristech’s patented technology and he expects that when mass produced, the cost of the two systems would be similar.

“Our motor control strategy separates commutation and power control, which means the electrical switching frequency need be no higher than running speed," he said. This is a fundamentally new approach that dramatically reduces the cost of many key switching components while ensuring exceptionally accurate high-transient speed control."

The strategy would make permanent magnet technology cost-effective, he claimed, "meaning that for the first time an eSupercharger can run continuously at boost levels of 2.5 bar or more.”

The technology is applicable to both diesel and gasoline engines. “In the face of increasingly restrictive legislation, diesels are relying on filter systems to remove particulates from the exhaust, increasing the back pressure," Richards noted. "It makes more sense to convert the particulates to useful energy in the combustion chamber, rather than filtering them out of the exhaust. The ability to match the air supply to the fuel input at low engine speeds by using an eSupercharger with lag-free response to transient changes would both cure the emission problem and improve fuel economy.”

Significant BMEP gains

Aeristech claims industry-leading power density and low inertia for the motor in its eSupercharger, which accelerates to 150,000 rpm with a transient response of idle-to-target speed in under 0.4 s. The company has successfully subjected its technology to independent evaluation by Ricardo and Mahle Powertrain U.K.

Richards said that Ricardo had carried out detailed modeling of a 221-kW 2.0-L gasoline engine with a single-stage turbocharger using Ricardo’s WAVE simulation software. Adding a 48-V Aeristech eSupercharger enabled the turbine to be increased in size by 80%, "improving BSFC [Brake Specific Fuel Consumption], torque and transient response throughout the engine speed range," he said.

Ricardo concluded that without the eSupercharger only a larger engine could have met the requirements, if relying on a conventional single-stage turbocharger, according to Richards. Mahle demonstrated the 48-V eSupercharger in a D-segment appraisal vehicle using its downsized 1.2-L 3-cylinder gasoline engine. Originally configured with 2-stage turbocharging, the engine achieved 144 kW (193 hp) and just over 30 bar BMEP.

"When the smaller turbo was replaced by the eSupercharger, allowing the larger turbo to be re-optimized, the engine achieved a maximum power output of 193 kW and a remarkable 33-bar peak BMEP at 2000 rpm," Richards reported. He said torque was increased over the entire speed range with a maximum value of 313 N·m (231 lb·ft); BMEP at 1200 rpm was increased from 20 bar to almost 29 bar.

"Mahle Powertrain U.K. has said that this is a higher torque per unit of cylinder capacity than any series production engine,” he noted. The eSupercharger directly influences the high torque figure, Richards claimed, and is also indirectly responsible for the increased power output. By replacing the smaller turbo in a two-stage turbocharging arrangement with the eSupercharger, the Mahle engineers were able to increase the size of the main turbo with satisfactory drivability and transient response.

For a future C-segment vehicle aiming at CO2 emissions of 95 g/km, Richards predicts greater levels of downsizing than even the most ambitious of today’s engines. He said a highly boosted 800cm3 engine with an eSupercharger can develop the power and torque of a conventional 2.2-L naturally aspirated unit, "providing equally satisfying throttle response but with much lower fuel consumption."

Author: Stuart Birch

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Stuart Birch

- 行业:汽车

- 主题:动力与推进力