首批A350-1000机翼目前正在位于北威尔士的布劳顿空客工厂进行组装。

首批A350-1000机翼目前正在位于北威尔士的布劳顿空客工厂进行组装。 首批次A350-1000机翼已在位于北威尔士的布劳顿空客工厂开始组装,该机翼将使A350-1000速度更快,效率更高,噪音更小。

首批次A350-1000机翼已在位于北威尔士的布劳顿空客工厂开始组装,该机翼将使A350-1000速度更快,效率更高,噪音更小。 A350-1000机翼与已投入运营的A350-900机翼有相同的翼展,但90%的零部件都经过了改动。

A350-1000机翼与已投入运营的A350-900机翼有相同的翼展,但90%的零部件都经过了改动。

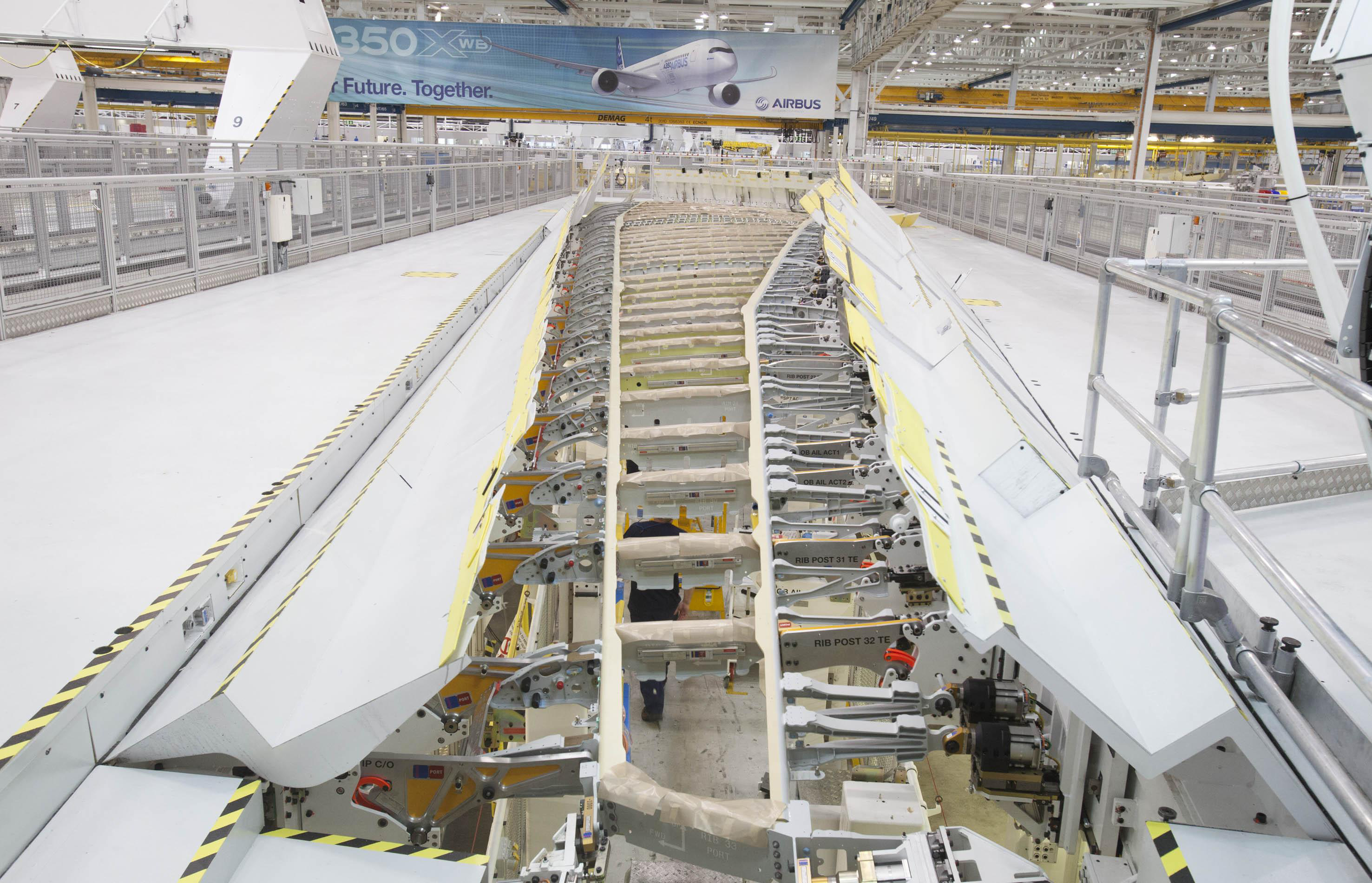

首批空客A350-1000机翼已在北威尔士的布劳顿(Broughton)开始组装。A350-1000的机翼翼展与已投入运营的A350-900相同,但90%的机翼零部件经过了改动,且机翼后缘有所延长,目的是加大机翼面积,以满足更大载荷和更长航程的要求。

A350 XWB机翼的大部分是由碳纤维复合材料构成的,包括其上下翼面。机翼长32米,宽6米。空客表示,该机翼是民航业目前在用的最大的复合材料单体部件。

该机翼在位于布里斯托(Bristol)附近费尔顿(Filton)的空客工厂进行设计和开发,工厂也负责设计和测试其他飞机系统,包括燃油系统和起落架。机翼设计中包含了许多流线型特征,尤其是下垂式机翼前缘组件,以及新型自适应下落式铰链襟翼,这些设计可以提高飞机低速飞行的效率。同时,机翼也能产生更多升力,并自动处理表面载荷,这有助于减少飞机阻力,并降低油耗。

空客的工程师们也将空气动力增强技术结合到了A350 XWB机翼中。这一技术已在A380机翼上得到了验证。为了提升飞机高速飞行效率,A350 XWB可以对襟翼的倾斜角度进行了不同的设置,以优化机翼构型,并更好的控制机翼载荷。机载计算机系统将对机翼的移动曲面进行智能控制,从而使机翼做出相应的反应,目的是为了让空气动力效率在不同的飞行阶段都实现最大化。实际上,飞行员将不仅能在飞机起飞和降落阶段使用襟翼,在巡航阶段也可以使用,以降低机翼阻力。

作者:Jean L. Broge

来源:SAE 《航空工程杂志》

翻译:SAE 上海办公室

First Airbus A350-1000 wing goes into production in North Wales

Airbus has begun the assembly process on the wings for the first Airbus A350-1000 in Broughton, North Wales. The A350-1000 wing has the same span of the A350-900 that is already in service, but 90% of the parts have been modified and the trailing edge has been extended to resize the wing for the additional payload and range.

Most of the A350 XWB's wing is comprised of carbon-fiber composites, including its upper and lower covers. At 32 x 6 m, Airbus says the wing is the largest single part made from composites in use in civil aviation today.

The wings were designed and developed at Airbus’ facility in Filton, near Bristol, where a number of other systems are designed and tested including fuel systems and landing gear. The wing design includes several streamlined features, in particular droop-nose leading edge devices and new adaptive dropped-hinge flaps, which increase the jetliner’s efficiency at low speeds. Also, the wings are capable of producing more lift and automatically handle loads across their surface—helping to reduce the aircraft's drag and fuel burn.

On the A350 XWB wing, Airbus engineers combined aerodynamic enhancements already validated on the A380 with further improvements. To improve efficiency at higher speeds, the A350 XWB can deflect its wing flaps differentially, optimizing the wing profile and providing better load control. By intelligently controlling the wing’s moving surfaces using onboard computer systems, the wing will adapt while airborne—tailoring it for maximum aerodynamic efficiency in the various phases of flight. In essence, pilots will be able to use the flaps not only for takeoff and landing, but also while cruising to reduce wing drag.

Author: Jean L. Broge

Source: SAE Aerospace Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Jean L. Broge

- 行业:航空

- 主题:制造