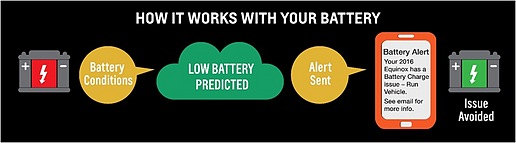

使用实时监控技术的预诊系统,可探测到即将发生的问题,并通过发送车内显示信息、智能手机短信、邮件及远程提示,将信息告知车主及其选择的信息接收方。

使用实时监控技术的预诊系统,可探测到即将发生的问题,并通过发送车内显示信息、智能手机短信、邮件及远程提示,将信息告知车主及其选择的信息接收方。 电池失效的预诊流程。

电池失效的预诊流程。 齿轮齿上的点蚀仅占齿轮总面积的3%,低于通常的损坏认定基准值4%,但在振动测试中仍能够识别出来。

齿轮齿上的点蚀仅占齿轮总面积的3%,低于通常的损坏认定基准值4%,但在振动测试中仍能够识别出来。

“我的车还能跑多久?”这是车主在修车时经常问修理工人的一个问题。如果只考虑更换轮胎和刹车的话,也许还能给出一个“最乐观的答案”,但车里其他部件和系统的寿命,估算起来则复杂得多。有一个很有说服力的例子是,人们经常会担心:“下次插入钥匙时车辆还能启动吗?”这也说明了为什么预诊系统成为越来越受人关注的一个技术领域,因为它能够预测系统与部件的剩余寿命。在2015 SAE世界大会上,由Delphi公司国际车载通讯部Tim Cavanaugh领导的嘉宾讨论会,从通用汽车的车辆健康监控系统谈起,对此进行了深入的讨论。

重点关注启动系统的部件

自电子模块开始用于电动汽车和插电式混合动力车以来,它们就与电池组和控制电子技术息息相关,因为电池容量和汽车里程对车辆来说至关重要。哪怕只有一点电池劣化,也会引起重大问题,特别是对经常需要驾驶较长距离的车主而言。

重型车也会碰到这个问题,正如讨参与讨论的嘉宾之一,Mahle Powertrain公司的传动系校验与控制经理Bernie Porter所说的那样,“没人想开一辆随时会在半路抛锚的车。”而在航空业内对预诊关注已久,因为这是强制维修的一部分,对安全与成本之间的平衡非常重要。

尽管Porter认为在汽车上投资巨额开发该技术“很难在商业上获利”,但通用汽车的综合汽车健康管理研究员Steven W. Holland指出了客户满意度的问题。

Holland向参会人员透露,通用汽车开始研发传统乘用车的预诊系统时,主要关注的是电池、起动机构和燃油泵,因为它们是确保车辆正常启动的关键部件。如果预诊结果为“阳性”,那么随之生成的“汽车健康报告”就能给车主提供非常有用的信息,而不是一些为了诱使他们前去换油或购买其他保养服务的推销信息。

Holland表示,通用汽车预诊系统的理念是以客户为中心,而且比起高质量,客户更加看重的是可靠性。如果软件的预测功能可以达到90%的精确度,准确评估一个部件什么时候可能会失灵,这将大大提升客户对汽车可靠性的印象。如果一名车主告诉他的朋友,尽管他的爱车启动和运行都很正常,但他仍获得了免费更换电池的服务,那么他就已为预诊系统做了宣传。

需要使用4G网络

汽车的部件或系统可能需要经过特殊设计,因为预诊算法需要的信息并非日常可以随时提供的信息,只有获得更加充分的信息,才能以较高的准确度判断是否需要进行部件更换。

尽管这些算法因车而异,而且一个停车-重启系统可能需要使用1个AGM(吸附式玻璃纤维棉)电池,或两个常规电池(而非一个电池),但通用汽车首次部署该技术时所使用的电池并未经过特殊设计。Holland表示,最重要的是,不能让车主在更换电池后发现电池健康评估的结果变差了。任何特定的要求,如电池温度传感器,都会安装在外部,而电压/电流监控装置则负责对电路的状况进行诊断。

这种算法的一个重点是,它能在车主每次启动车辆,而不仅仅是电压跌落时提供有关电池、启动器、燃油泵以及其他系统的详细信息。具备预诊功能的汽车能通过OnStar 4G网络传输这些信息。如果没有通过4G网络按需获得信息的能力,那么算法的配置也将无从谈起。

车辆的健康算法并不是基于故障代码或其他一些明显的劣化现象开发的。Holland表示,一个修车技师所采集的读数可能看上去非常正常,但是预测系统的精髓则在于分析读数的变化,这些变化背后隐藏着可能发生的问题。

燃油泵案例

Holland在讨论中介绍了电子燃油泵的案例。一只全新的燃油泵可以提供远超所需的压力和油量。所以一旦算法发现,尽管这些数据仍处于可接受范围内,但其下降速率高于正常水平,那么监控系统便会提高警觉。接着算法会留意硬加速和高负荷可能对此造成的影响,但这些步骤都是在车主发现任何异常情况之前完成的。

有些信息也来自于“隐藏代码”——这是软件自带的算法,在其他任何维修诊断系统中都没有。这些算法自安装起开始,就是校准开发流程固有的一部分,永不移除,并且现在人们发现可以将它们用于辅助某些预诊决策。

Holland表示,如果一份通用汽车的健康报告提醒车主需要在保修期内更换电池,这份报告必定是正确无误的,“通用不会承担任何风险,因为买单的人是我们自己。如果我们不买单,客户肯定会感到非常不安。”

他还指出,来自各家供应商的所有电子元器件都有一个普遍的问题——专利代码内嵌在元器件中。“我们需要从那个代码中获取与健康有关的参数。”

一些参会者认为,直接将预诊决策传送至汽车经销商的做法,可能会对售后市场造成冲击。但也有人指出,汽车健康报告也可能会发送给车主以及由他指定的“优先服务供应商”——这很可能是一家独立维修店。

为将4G数据计划的影响降至最低,预诊算法的设计非常谨慎。正如Delphi的Cavanaugh所说,“我们不能事无巨细地收集所有信息,而要将数据请求缩减至我们需要的时间和内容范围内。”

云服务器上的诊断算法

诊断/预诊信息被传送至通用汽车的云端服务器,因此无需安装任何车载算法。车载算法不仅需要占用计算机容量,还需要进行连续数据总线重新编程,以维持正常运转。Holland表示,车主可以自行选择是否需要预诊报告。“如果他们需要,”那么通用公司会在5年内提供车载通讯网络, “如果他们不需要,我们就不提供。”

Holland还对预诊分析和“发动机检查灯”这类提示功能之间的差别做了详细的解释。他说,“政府规定我们必须在车上安装提示功能,当发生问题时,指示灯必须亮起。”他补充道,但是这可能意味着车辆在3个月后才需要维修,也有可能意味着需要马上处理,又或者发生问题的原因也可能是油箱盖松动了,不管原因是什么,提示灯都会亮起。“因此车主必须具备一定的经验,才能选择在车辆没有明显问题的时候,忽略这类提示。”

将来,预诊系统还有可能预测自动变速箱等机电系统的寿命。他们已经具备了传感器,可读取液压管压力、输入轴和输出轴的转速、离合器啮合状况等信息。

振动分析

捷克布拉格科技大学的Mohamed El-Morsy提出,未来的预诊系统还有可能预测齿轮和轴承的失效。他介绍了一个有关5速手动变速箱的实验室测试。研究人员在该变速箱的一个齿轮齿表面上制作了一个微小的点蚀,用一个名为Morlet的小波滤波器对其进行分析并用Kurtosis统计方法测量一个振动信号中波峰的数量和振幅。El-Morsy表示其大学正在与斯柯达合作开发该项目,旨在将实验室研究成果应用到车内变速箱,而这自然会需要使用传感器。

GM prognostics use 4G for data acquisition, cloud analysis

“How much longer will it last?” is a common question that motorists in for repairs ask service technicians. And although a “best guess” may be fine for deciding when to replace tires and brakes, other vehicle parts and systems raise more time-sensitive questions. “Will the car start the next time I turn the key?” is an example, and that’s where prognostics—predicting remaining service life of systems and components—is becoming a technical area of increasing interest. Panelists took a fresh look at a 2015 SAE World Congress panel led by Tim Cavanaugh, Global Telematics, at Delphi, using a new General Motors vehicle health monitoring system as the springboard.

Focus on starting system parts

Electronic modules have been keeping a close watch on the battery packs and control electronics of electric vehicles and plug-in hybrids since their introduction, because battery capacity and vehicle range are important. Any deterioration is of great concern, particularly for a motorist expecting to make trips of a specific distance on a regular basis.

Heavy-duty vehicle fleets also are in the picture, for as panelist Bernie Porter, Manager of Powertrain Calibration and Controls for Mahle Powertrain noted, “they don’t want a piece of machinery to end up sitting in the middle of nowhere.” Of course, the aviation industry has a long-established focus in this area, as part of required maintenance, seeking to balance safety with cost-effectiveness.

Although Porter said “it’s harder to make a business case” for a major investment in a car, the issue of customer satisfaction was noted by Steven W. Holland, GM Research Fellow for Integrated Vehicle Health Management.

He told attendees that the initial GM entry into prognostics for conventional passenger cars is focused on the battery, starter, and fuel pump, because these are the key components that must be healthy for the car to start. The “positive” nature of the prognostics takes the Vehicle Health Report a giant step past what many motorists consider a sales pitch for oil changes and similar maintenance items.

The GM prognostics approach is customer-centric, Holland said, and added that it’s not really quality but reliability that the customer perceives. If the predictive nature of the software can become 90% accurate in determining when a component falls out of spec, that would greatly enhance the impression of reliability. The motorist who can tell his/her friend that the battery was replaced free even though the car was starting and running fine, would be a salesman for prognostics.

4G connection required

The parts or systems may have to be built to a specific design because the prognostics algorithm needs information that might not necessarily be routinely available so that a decision to call for replacement is made with high confidence.

For GM’s initial foray, the battery is not a special design, although the algorithms vary according to vehicle, and perhaps one AGM (absorbent glass mat) battery or two conventional batteries could be used (instead of one) for a stop-restart system. For the most part, Holland said, the motorist should not experience a loss in effectiveness of the battery health assessment with a replacement battery. Any specific requirements, such as a battery temperature sensor, would be external, and any voltage/amperage monitoring would be in place for diagnostics of electrical circuits.

An important aspect of the algorithm is that there’s detailed information on the battery, starter, and fuel pump—and other systems—every time the motorist starts the car, not just the cranking voltage drop and the time to start. That information is transmitted by the OnStar 4G connection in the cars that have the prognostics feature. Without the ability to get information on demand via 4G, there would be no practical way to deploy the algorithm.

The vehicle health algorithms are not based on trouble codes logged or even some obvious deterioration. The readings a technician takes would look absolutely normal, Holland said. But the sophistication in the prognosis is based on changes in readings that indicate an impending problem.

Fuel pump example

Holland pointed to the electric fuel pump as an example. When new, the pump can deliver a lot more pressure and fuel volume than is needed. So when the algorithm sees numbers that still are within the acceptable range, but are declining at a rate beyond expectations, the monitoring will become more intensive. The algorithm will look for signs of an impending effect on hard acceleration and high loading, but before the driver is likely to notice anything, he said.

Some of the information also comes from “hidden code,” which are algorithms that are in the software but not in any service diagnostics. These algorithms were installed (and never removed) as part of the calibration development process and now have been found to help make some prognostics decisions.

Holland said that when a GM health report calls for battery replacement under warranty, the health report is so robust that “there’s no risk to GM because we’d eventually be paying for it anyway. If we didn’t, we’d just have an upset customer.”

He noted there is an overall challenge posed by all the electronic components from suppliers, who have proprietary code baked in. “We need the indicators of health” from that code, he said.

Some session attendees expressed concern over the possibility that the prognostics decisions, transmitted to the car dealer, would shut out the aftermarket. However, others pointed out that the “vehicle health report” would go to the motorist and his designated “preferred service provider,” which could well be an independent garage.

To minimize the effect on the vehicle’s 4G data plan, the prognostic algorithms are prudent users. As Delphi’s Cavanaugh said, “you don’t want to grab everything. You want to reduce the data requests to just when and what you need.”

Diagnostics algorithms on cloud server

Diagnostics/prognostics information is transmitted to GM’s cloud server, which eliminates the need for onboard algorithms that not only would take computer capacity, but also require continuous data bus reprogramming to maintain currency. The prognostics reports are strictly voluntary for the motorist, Holland explained. GM provides the telematics connection for five years “if they want it. If they say no, we don’t enable it.”

Holland distinguished the prognostics analysis from anything that turns on a Check Engine light. He pointed out that “the government says we must have it and light it when certain things happen.” There’s no difference, he added, between something that’s three months to a needed service, something right now, or even the loose gas cap. “So the motorist has become trained to ignore it (the light) when there’s no obvious problem.”

Prognostics also has a future in predicting future life of such electromechanical systems as automatic transmissions. They already have sensors that read hydraulic line pressure, input and output shaft rpm, and clutch engagements, so predictive capabilities are there.

Vibration analysis

The future also could include ways to detect impending failure of gears and bearings, explained Mohamed El-Morsy, of the Czech Technical University of Prague. He described laboratory testing of a five-speed manual transmission that had a pitting fault introduced on a small part of the surface area of a gear tooth. It was subject to a specific wavelet filter (Morlet) with a statistical measure (Kurtosis) of the number and amplitude of peaks in a vibration signal. Taking the laboratory work into an in-car transmission requires a sensor of course, and El-Morsy said the university is working with Skoda to develop one.

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Paul Weissler

- 行业:汽车

- 主题:电气电子与航空电子