无人机空拍:AstaZero测试场地包括“超级高速公路”。

无人机空拍:AstaZero测试场地包括“超级高速公路”。 AstaZero虚拟世界的视图,包括无人机。

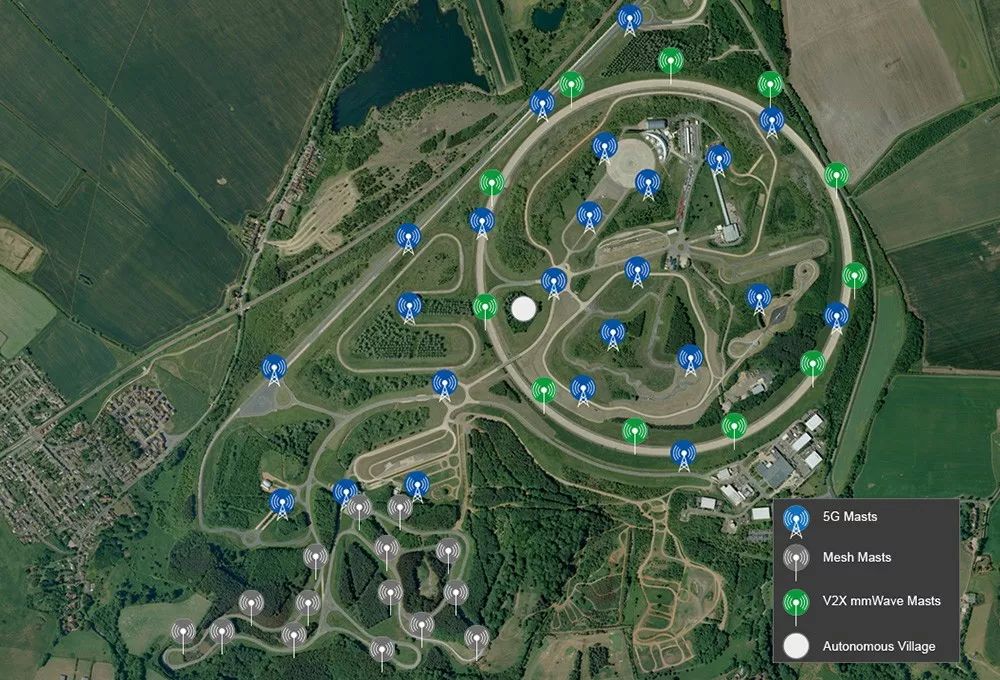

AstaZero虚拟世界的视图,包括无人机。 Millbrook的5G网络塔定位并由“光纤主干”连接。

Millbrook的5G网络塔定位并由“光纤主干”连接。 由英国的HORIBA MIRA创建的虚拟街道。

由英国的HORIBA MIRA创建的虚拟街道。 由英国的HORIBA MIRA创建的虚拟街道。

由英国的HORIBA MIRA创建的虚拟街道。

在创新自动驾驶汽车的研发世界中,信任、安全、保障,这些关键字就像是一个魔咒,时时萦绕在每一位工程师、研究人员和设计师的脑海中。为了让自动驾驶汽车真正成为一种为大众所接受的可靠技术,这些都是必须克服的挑战。

不过,还有一个同样不容忽视的关键字,那就是测试。为了赢得大众对自动驾驶汽车的信任,汽车行业必须针对自动驾驶汽车的整体及各个组成部分进行大量测试,其深度与广度均将远超出以往任何时间。在此背景下,供应商和政府机构也专门建立了大量试验场,为支持汽车原始设备厂商的自动驾驶汽车事业,以及推动 SAE 5 级自动驾驶汽车的大规模普及作出了重要贡献。

整体来说,这些机构主要采用了“虚实结合”的测试方式,也就是“虚拟测试工具”结合“真实世界测试”。最近,在欧洲地区,位于瑞典 Borås 的 AsTazero 5G 试验场已经正式揭幕启用(其他类似的设施还包括位于英国的 Milbrook 试验场和位于英格兰的 HORIBA MIRA 试验场)。AsTazero 5G 试验场是瑞典研究所(RISE)与哥德堡查尔莫斯理工大学的成功合作成果,内部设置了多条高速公路测试道路,且已广泛覆盖 5G 网络。

AstaZero 成立于 2014 年(不过,瑞典研究所自身的自动驾驶研发工作则可以追溯至2008 年),据称为世界上首座致力于地面车辆自动驾驶和主动安全测试的设施,能够“模拟世界任何城市中的几乎任何交通状况”。正如上文介绍,AstaZero 正是通过“虚实结合”实现这一点的,即借助 5G 连接和分布式云服务,将虚拟世界和现实世界的交通环境混合起来,且还可以加入“行人”等可变参数,进一步增加测试环境的复杂度。

揭幕仪式上,AstaZero 首席执行官 Peter Janevik 表示:“很显然,汽车行业必须具备更好、更快、更复杂的测试设施,否则很难真正启动公共道路上的真实自动驾驶产品测试。”Janevik 先生称,AstaZero 园区(现已具备复制几乎所有车辆行驶环境的能力,包括非公路车辆)可以提供世界上最先进的测试环境。借助于 5G 连接的超高传输速度和准确性,AstaZero 试验场可以复制现实世界中的几乎所有真实交通状况,“这是以往任何试验场都做不到的”。

虚实结合

AstaZero 园区将同时启用“实体测试车辆”和“虚拟测试车辆”,在测试循环中运行现实世界中的应用程序,并创造了一种“有自动驾驶汽车参与”的交通环境。AstaZero 试验场中还设置了自行车道、城市环境(考虑到目前全球城市化进程的脚步,这点尤为重要)、乡村道路和多车道高速公路等交通环境,理论上可以考虑行人(比如人行道上的大量行人),甚至无人机对自动驾驶汽车行驶的影响。

AstaZero 试验场还通过与 WARA-CAT、爱立信(Ericsson)和 PTS 等供应商的合作,实现了 5G 通信网络的广泛覆盖,并具备了与电信运营商、终端用户设备与第三方开发者合作的能力。在 Janevik 对 AstaZero 试验场的规划中,国际数据共享是非常重要的一环。目前,AstaZero 试验场在欧洲、美国和远东均有合作伙伴,并希望见到自动驾驶汽车测试系统的 ISO 标准化,以促进全球不同地区测试结果的相互比较,这对“促成自动化车辆的大量测试”至关重要。

行业颠覆者

英国 Millbrook 试验场首席自动驾驶汽车工程师 Peter Stoker 认为,建立国际合作机制非常重要,但我们同时也必须意识到行业颠覆者的存在。“没错,现在国际上正在讨论建立合作机制,但我们也必须意识到一些行业颠覆者的存在,”Stoker 解释道,“这些颠覆者可能不是汽车制造商,反而很多都是一些试图突破技术边界的初创企业。然而,他们的技术到底是否具备与我们合作的基础?这点我们真的说不准。”

Stoker 认为,Millbrook 试验场具备一系列世界一流的真实世界驾驶设施,在自动驾驶汽车测试中最重要的任务莫过于打造安全系统。“我们可以确保所有开发工作都是在一个安全、可靠的环境下进行的,而且都可以经过适当的测试。”他表示,“事实上,一些汽车消费者可能觉得现有的先进驾驶辅助系统(ADAS)已经有点太过了,而另一些人却觉的还不够。但无论如何,汽车行业都必须确保自动驾驶汽车可以赢得大众的绝对信任。

“如今,有关自动驾驶的炒作从来没有停止,但我们必须明确告诉大家,自动驾驶汽车并不会在未来几年中大量出现在人们的生活中。”Stoker 强调,“而且,即使自动驾驶汽车最终真正到来,也一定是先在有限区域中进行有选择性的逐步推广,比如“货物运输”和“最后一英里通勤”等行驶路线较为固定的行驶场景,这都将帮助社会逐渐接受自动驾驶技术。”

原子能合作机构

目前,Millbrook 试验场还在进一步扩大其自动驾驶汽车测试能力,除了现有的大约 70 公里的测试轨道,还计划增加更多测试台。此外,Millbrook 试验场还有一个看起来很不相关的合作伙伴—英国原子能管理局(UKAEA)。英国原子能管理局有一个下属机构,名为 RACE(Remote Applications in Challenging Environments),正在利用自动引导车(AGV),比如轮式机器人等,处理各种任务方面具有丰富的经验。

英国原子能管理局的 Culham 科学中心占地约 200 英亩,其中设置了大约 10 公里的测试道路。不过,Millbrook 和 Culham 的最大区别在于:Millbrook 实质为一个几乎没有行人的封闭环境,而 Culham 则更像是一个非常安全的大学校园,其中有很多行人、丁字路口、二层小楼及其他各种常见道路场景。Stoker 表示:“我们与电信设备供应商有大量合作,安装了许多桅杆,实现了通信网络的广泛覆盖。”目前,这些站点之间可进行无缝信息传递,实现互联。

不过,Millbrook 试验场的全部 5G 研发均由 AutoAir 财团支持,主要扮演“5G 试验台”的角色。AutoAir 是一家由英国政府资助的财团,其成员包括迈凯轮应用技术公司(McLaren Applied Technologies)。目前,在 LTE 通信供应商 Airspan Networks 的帮助下,Millbrook 试验场正在进行适用自动驾驶汽车的 5G NR 技术开发。

目前,Millbrook 试验场的 5G NR 项目主要是对这种新型通信技术进行适配,使其适用于自动驾驶汽车的验证与研发。Stoker 补充说,“试验台是我们的,但开发主要是财团方面进行的。”现阶段,试验台上有 23 个通过光纤主干连接的基本单元,可在测试道路附近提供低延迟的广域 5G 通信,提供实时 Gbps 连接服务,而这被视为 SAE 3 级到 5 级自动驾驶汽车验证工作的必要条件。

除了 5G NR 项目,Millbrook 试验场的另一个新项目是模拟套件研发。该套件可以提供试验场内所有硬表面车道的数字模型(来自软件专家 RFPro),供OEM和供应商使用,精度非常之高。“当项目研发完成后,厂商可以将自己的车辆送到 Millbrook 试验场,然后开始各种虚拟环境测试。”Stoker 表示:“技术的演示非常重要,而且更重要的是在真实环境中完成这一切。目前,保险公司已经对我们在 Millbrook 的工作产生了浓厚兴趣。”

Stoker 表示,自动驾驶汽车的实车测试需求还将继续存在,但 80% 到 90% 的研发工作是可以通过虚拟手段实现的。

极限控制测试

HORIBA MIRA 试验场位于英格兰 Midlands 地区。该试验场的自动驾驶汽车测试负责人 Chris Reeves 也认同“虚实结合”的测试方法,即在设计和工程阶段利用模拟和建模获得更多信息,并最终在真实世界中进行测试和验证。“HORIBA MIRA 拥有世界首套自动驾驶汽车测试城市驾驶环境及相关基础设施,”Reeves 表示,“我们还在搭建一处新的设施,从而进行更高层次的系统控制极限测试。”

Reeves 表示,自动驾驶汽车测试的一个重要部分是理解“边缘情景”,但我们很难在真实世界中大量复现极端环境,这并不现实。此时,模拟和建模的方法就可以发挥重要作用了。Reeves 表示,“我可以举一个很简单的例子,当我们在测试汽车的极端性能时,车辆可能已经接近,甚至已经处于失控状态。这时,在真实世界中进行这些测试是非常危险的。”Reeves 表示,自动驾驶汽车可以带来的社会和环境效益是无需多言,“只要我们能够建立足够的信任,就可以让大众享受更加包容的移动出行解决方案。”

实话实说

Reeves 表示,根据我们与OEM合作的经验,汽车行业的自动驾驶汽车研发主要有两种措施:第一种为“一步到位式”,也就是直奔非常高水平的自动化级别,也就是直接达到 SAE 4 级和 SAE 5 级自动驾驶;第二种则为“循序渐进式”,即利用汽车行业中已经存在或即将出现的技术,逐步对车辆的自动化功能进行优化,进而提高车辆的便利性和安全性。与 Millbrook 的 Stoker 的一样,Reeves 也视“货物运输”和“最后一英里”为迈向高级别自动驾驶汽车的明智之举。他表示,“这种措施更加安全可靠,并可以在一定程度上规避公共道路测试所需的各种要求。”

HORIBA 是一家总部位于日本京都的测量和测试系统生产商,在 2015 年收购了英国测试机构 MIRA。那时候, MIRA 已经在自动驾驶汽车测试方面积累了 10 年经验,是最早一批预见到汽车行业重大变革并主动采取行动的公司之一。如今,HORIBA MIRA 正在扩建一个长度为 1079 米,最大宽度为 300 米的新测试设施,从而打造一个更加灵活的驾驶环境。目前,HORIBA MIRA 已具备“多条”测试道路,包括越野和城市驾驶环境。

自动驾驶汽车何时才能在欧洲和美国大量出现?Reeves 表示,实话实说,这个问题没有一个简单的答案。“SAE 4 级和 SAE 5 级自动驾驶功能可能还要十几年才会真正出现在公共道路中,而且在此后很长一段时间中,我们仍将生活在一个传统汽车和自动驾驶汽车共存的道路环境中。在可预见的将来,人们仍将承担一定驾驶任务。”

Trust, safety, security. Those words form a mantra that needs to be in the forefront of the mind of every engineer, researcher and designer responsible for creating the brave new world of autonomous vehicles (AV). They are the standout “musts” of a lexicon that describes the dangers and challenges in making AVs a credible, and publicly accepted technology.

But there is one more “must”: testing. To engender public confidence, it has to be taken to a breadth and depth that the auto industry has never before experienced, involving every component and aspect of integrated autonomy. Playing a major part in this by supporting OEMs, suppliers and government legislators are dedicated testing facilities that will enable SAE Level 5 autonomy to become a high-volume reality.

These facilities are developing virtual tools in conjunction with the physical testing environment to speed the acceptance of every aspect of AVs. In Europe, a member of this select group is the recently unveiled AstaZero 5G facility in Borås, Sweden (others include Millbrook and HORIBA MIRA). It includes a high-speed multi-highway track and 5G capability and is a partnership between the Swedish state-owned Research Institutes of Sweden (RISE), and Chalmers University of Technology, Gothenburg.

AstaZero was established in 2014 (although early self-driving work was carried out by RISE in 2008). It describes itself as the first test facility in the world dedicated to automated driving and active safety of ground vehicles that is “able to simulate almost any traffic situation in any city on Earth.” It does this by blending virtual and real-world traffic complexity and pedestrians on its track, using 5G connectivity and distributed cloud services.

Peter Janevik, CEO of AstaZero said at the unveiling: “The automotive industry clearly needs better, faster and much more complex test facilities before new self-driving products can be safely tested on public roads.” He described the facility (which has the capability of replicating scenarios for almost any vehicle, including off-highway) as having the world’s most advanced test environment, the use of 5G providing the speed and accuracy that can replicate real-world traffic complexity “unlike anything that’s been seen before”.

Mixing and matching

It does so by mixing test vehicles with virtual vehicles; runs real-world applications in the test loop; and creates theoretical traffic environments in which autonomous vehicles share roads taking into consideration the effect of populated sidewalks (pavements) and even the presence of drones. Test areas at Borås include bicycle, city (significant in view of global population drift towards urbanization), rural road and the high-speed multi-lane.

Use of the 5G network (developed in partnership with WARA-CAT, Ericsson and PTS) includes the ability to work with telecom operators, plus end-user equipment and third-party developers. International data sharing is very much on Janevik’s agenda for AstaZero, which has collaborative partners in Europe, the US and the Far East, and wants to see an ISO standardized testing system to facilitate worldwide comparable results, vital to make the “massive amounts of testing for automated vehicles feasible."

The disruptors

In the UK, Peter Stoker, chief AV engineer at Millbrook Proving Ground, is well aware of this but also of the need to be cognizant of business disruptors. “Yes, there is now international discussion about co-operative systems, but we have to consider disruptors,” he explained. “These are not vehicle makers. Many are start-ups trying to push technological boundaries. How co-operative their technologies will be we really do not know.”

With its range of real-world driving facilities, Stoker sees Millbrook’s overarching AV task as achieving safe systems. “Ensuring that everything is developed in a safe and reliable way – and properly tested,” he said. “Some members of the car-buying public may already feel that ADAS is doing more than it should; others are expecting more of their vehicles than they can deliver. The auto industry needs to ensure that absolute trust is engendered.

“There is a lot of hype around. We need to put out a clear message that full [automated driving] will not come for cars in large numbers any time in the next few years,” he stressed, “and when it does there will be a selective roll-out in defined areas. Firstly, freight and ‘last mile’ use such as vehicle delivery on the same route every day. It will help society become used to self-driving vehicles.”

Nuclear partnership

Millbrook is expanding its AV test capability (it has 70km of test tracks) with more testbeds and is working with what may seem an unlikely partner, the UK Atomic Energy Authority (UKAEA). UKAEA has a division called RACE (Remote Applications in Challenging Environments) which has experience in automatically guided vehicles (AGV) – wheeled robots – tackling a variety of tasks.

UKAEA also has some 200 acres of land and 10km of roads at its Culham Science Center. The difference between Millbrook and Culham is that the former is a confidential environment with few pedestrians, while the latter is like a very secure university campus with many pedestrians. It has T-junctions, 2-storey buildings and common road scenes. “We have introduced extensive communications, linked with a telecoms equipment supplier to establish a connected environment and installed lots of masts,” Stoker said. The sites interlink via seamless information transfer.

All 5G development at Millbrook, though, comes under the aegis of a UK government-sponsored consortium to provide the transport element of the “5G Testbed”. The consortium, called AutoAir, includes McLaren Applied Technologies. Led by LTE vendor Airspan Networks, it is developing 5G New Radio (NR) for AVs.

The project will aim to make 5G NR technologies available for the validation and development of AVs. “We host the test bed but the consortium does the development,” added Stoker. There are 23 base units linked via a fiber backbone, providing a low latency, wide area 5G structure around the tracks, delivering the real-time Gbps connectivity regarded as crucial for SAE Level 3-5 validations.

Also new and a direct Millbrook project is a simulation suite that holds digital models (created by software specialist rFpro) of all the hard surface tracks at the facility to very high degrees of accuracy that can be used by OEMs and suppliers. “When project work is completed, a vehicle can be brought to Millbrook to correlate the virtual program and establish subsets,” Stoker said. “The key thing is demonstration of the technology and doing so in real environments. We are seeing insurance companies now becoming increasingly interested in our work at Millbrook.”

Stoker says he believes there will continue to be a need for physical testing of AVs to achieve verification although 80% to 90% of the development of a AV could be achieved virtually.

Limit of controllability

At HORIBA MIRA in the English Midlands, head of AV testing Chris Reeves agreed with the physical test-vehicle element, with simulation and modelling informing design and engineering stages and ultimately test and validation. “HORIBA MIRA developed the first urban driving environment for the testing of AV and associated infrastructure technologies,” Reeves said. “We are also creating a new facility that enables us to take systems to the limit of controllability.”

Reeves said that an important part of testing AV is to understand the “edge cases” – where simulation and modeling will play a major role because many of these tests will be impractical to reproduce within physical test environments. “For example,” he explained, “when a vehicle is being tested up to and beyond the limits of its controllability where it will be unsafe to do so in a physical environment.” Reeves says he believes the societal and environmental benefits of AVs are well understood: “Assuming we can create the level of trust required, we can help deliver an inclusive mobility solution.”

On the level

Working with OEMs, Reeves is experiencing two approaches to AV development by the auto industry. Firstly, the revolutionary – how to reach very high levels of automation (SAE Levels 4 and 5); secondly evolutionary, incremental progress to achieve more convenience and safety features using current and soon to emerge automated technology. Like Millbrook’s Stoker, he sees freight vehicles and particularly last mile applications as sensible steps on the incremental ladder to the high SAE Levels. “Not using it on a fully public road would enable control of the safety case and its requirements,” he said.

The Kyoto-headquartered measurement and testing systems producer HORIBA bought MIRA in 2015, a decade after the UK facility first became involved in autonomous vehicle testing, an early anticipator of a change that will totally reshape the global auto industry. Now it is expanding to incorporate a new facility 1070m in length and 300m maximum width to create flexible driving environments. HORIBA MIRA already has “multiple” test circuits embracing off-road and city driving areas.

When will we realistically see the mass appearance of AVs in Europe and the U.S.? There is no simple answer, Reeves said. “SAE Levels 4-5 on public roads are over a decade away. We will have mixed fleets on our roads for a very long time. For the foreseeable future people will enjoy taking part in the driving task.”

Author: Stuart Birch

Source: SAE Autonomous Vehicle Engineering

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Stuart Birch

- 行业:汽车

- 主题:质量、可靠性与耐久性安全性测试与检验