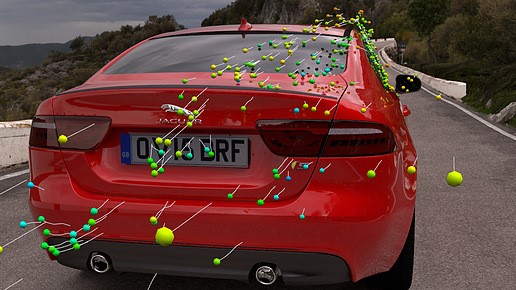

埃克斯空气动力模拟仿真软件在一辆捷豹XE上的应用。

埃克斯空气动力模拟仿真软件在一辆捷豹XE上的应用。 这辆捷豹XE轿车并不是真的烧着了,只是采用了埃克斯的可视化软件的仿真功能。

这辆捷豹XE轿车并不是真的烧着了,只是采用了埃克斯的可视化软件的仿真功能。 埃克斯欧洲分公司总裁Jean-Paul Roux。

埃克斯欧洲分公司总裁Jean-Paul Roux。 捷豹路虎特种车辆部(SVO)总监Mark Stanton。

捷豹路虎特种车辆部(SVO)总监Mark Stanton。 埃克斯设计与可视化总监Paul Stewart表示,借助仿真工具进行设计,可以让设计师与工程人员之间的沟通更加便利。

埃克斯设计与可视化总监Paul Stewart表示,借助仿真工具进行设计,可以让设计师与工程人员之间的沟通更加便利。

长久以来,汽车研发的主题总是离不开“重点”(换言之,就是“妥协”),在概念设计与工程制造之间找到平衡至关重要。

随着CAD和CAE软件解决方案的不断进步,可以说设计与工程之间“水火不容”的紧张关系已经得到一定程度的缓解,如今这种情况将进一步得到改观。据了解,捷豹路虎(JLR)及其密切合作的伙伴,也就是模拟软件开发专家埃克斯公司(Exa Corp.)表示,如今设计软件已经非常精密。到2020年,由于软件方面的进步,汽车厂商在进行车辆研发时可能不再继续需要实体原型车。

当然了,在汽车研发的最后阶段,打造一辆可以真正驾驶的原型车仍必不可少。但这两家公司表示,凭借埃克斯公司的综合可视化工具,以及捷豹路虎在软件应用方面超过十年的经验,这对合作伙伴将打造一款最先进的模拟仿真研发平台,并利用该平台逐步摆脱汽车研发中对实体原型车的依赖。

埃克斯欧洲公司巴黎分公司总裁Jean-Paul Roux解释说:“通过类似埃克斯PowerFLOW CAD工具中集成的可视化模块,汽车厂商得以在汽车设计的各个阶段内获得超真实的渲染效果,为设计师的工作提供便利。”

他断言,汽车的研发流程复杂多变,随着汽车厂商“逐步迈向未来”,那些使用常规软件进行沟通交流的日子早已成为过去。

他强调说,举例而言,如果能够更加清晰地了解一项新设计将对车辆的空气动力学性能带来哪些影响,我们就可以在设计师与工程人员之间搭建一条更加开放的沟通桥梁。“这样一来,除了完成自己的工作,双方还能同时考虑对方的难处和目标。事实上,这种作法并不会捆住设计师和工程人员的手脚,反而可以协助他们推出外观更加大胆且更加富有表现力的设计,还能同时提升车辆的空气动力性能。”

Roux表示,通过这些精密的可视化工具,汽车厂商得以“在最大程度”捕捉车辆周围的潜在气流或微气流,这是现有风道做不到的:“可视化工具允许设计与工程团队及时了解一些概念的变化,这点非常重要,因为这些变化可能会直接导致一些组件形状及其制造方式的改变。”

据了解,捷豹路虎在旗下XE轿车的研发中应用了埃克斯公司的软件系统,并最终在并未过多牺牲外形的前提下,成功将车辆的空气动力性能提升至0.26 Cd的超高水平。埃克斯道路交通应用部副总裁Ales Alajbegovic告诉《汽车工程》杂志,虽然很多竞争对手可能会觉得不可思议,但事实上,捷豹路虎在XE轿车的研发过程中并未使用任何空气动力实体原型车,一切有关空气动力性能的优化,均是通过埃克斯公司的Power FLOW模拟工具完成的。

捷豹路虎特种车辆部(SVO)总监、前任汽车设计总监Mark Stanton表示,“在所有现行捷豹路虎量产车型的研发中,我们均利用了埃克斯的软件工具来提升车辆的空气动力性能。此外,捷豹路虎F-Pace跨界车的研发也采用了模拟软件解决方案。具体来说,通过埃克斯的软件,我们在研发中实现了完美的提升平衡,从而为用户带来了真正动力十足的驾驶体验。

“我们还使用埃克斯的仿真软件来减少车辆的空气阻力,”Stanton继续表示,“我们在车辆的前保杆上设计了一些孔洞,从而优化车辆前角的气流流动,提高车辆的空气动力学性能。

Stanton表示,“所有这一切都是在虚拟环境中完成的。在此之前,我们未曾制造任何实体原型车。我们非常信任这些虚拟工具,只有在整个研发流程的最后阶段才采用了一辆实体原型车进行最终的验证。”

设计与工程联手

埃克斯公司设计与可视化总监Paul Stewart补充说,同一项目中的设计师和工程人员所关注的要点不同,工作时间安排也有差异,如果沟通不足的话,可能会经常处于不同步的状态。

“然而,如今一部分汽车厂商已经发现,埃克斯PowerFLOW等CAE软件中集成的可视化工具有助于促进设计与工程团队之间的沟通交流。”

Stewart表示,对于设计师与工程人员而言,模拟软件可以协助双方实时直观地了解任何设计变化:“这并不意味着设计师不得不在一些更加大胆的设计项目中前瞻后顾,不能放开手脚,恰恰相反,由于这种整体设计流程从最开始的阶段就鼓励跨部门的合作,设计师反而可以拿出更富有表现力且切实可行的设计方案。”

从空气动力性能优化到整车验证

埃克斯的发言人表示,捷豹路虎对自己定下的2020年目标非常有信心。通过与我们长达十多年的合作,这家汽车厂商已经显著降低了汽车设计过程中对原型车的依赖,特别是在研发的早期阶段。

Stanton已经确认,捷豹路虎计划在2020年前实现基于纯软件模拟的整车验证。届时,汽车研发将直接从虚拟世界进入最终量产环节,中间无需原型车的参与。“如今,埃克斯软件在捷豹路虎汽车研发中的地位非常重要。2014年,我们在埃克斯软件上的仿真应用时间为3600多万CPU小时,这相当于7000小时的实体车风道测试,所以你可以看到模拟仿真软件对我们来说非常重要。”

Stanton补充说:“捷豹路虎正在努力摆脱对实体原型车的依赖,而虚拟设计在这种转型中非常关键。借助虚拟设计,捷豹路虎可以远远领先其他公司,提前实现所有项目要求,并在早期阶段及时验证车辆的质量。”

同时,埃克斯公司的Alajbegovic断言,在产品研发阶段,使用模拟工具进行整车验证,可以节省大量的财务和时间成本。

“通过借助虚拟仿真进行设计,汽车厂商最大的收获在于可以提前发现问题,从而避免在研发最后阶段的返工。”Alajbegovic表示,“事实上,在项目后期发现的问题,并进行问题的纠正,可能会将新车上市的时间推迟1到2个月,而厂商可能因此损失数亿美元。此外,如果发现的问题需要更换生产设备和工具才能解决,这也同样会让厂商花费数百万美元。但如果使用了虚拟工具,我们则更有把握在规定的成本和时间范围内完成车辆设计。”

Alajbegovic补充说,除了这些流程上可能节省的开支,降低或摆脱对实体原型车的依赖,本身就可以显著降低成本。“单说原型车本身,打造一辆不能驾驶的陶土原型车大约需要50到100万美元,而为了进行早期测试,传统汽车厂商通常需要2到3辆原型车。”他说,“此外,由于对沿用件与原型零部件的不同选择,一辆可以驾驶的原型车的成本可能有所差异,但仍在50到100万美元之间,而为了进行实际测试,汽车厂商一般需要100到200辆可以驾驶的原型车。”

2002年,埃克斯公司在巴黎设立了办公室,从而进一步扩大了公司的客户群。除了捷豹路虎,如今埃克斯的客户还包括宝马(BMW)、德尔福(Delphi)、电装(Denso)、菲亚特克莱斯勒(FCA)、福特(Ford)、本田(Toyota)、现代(Hyundai)、日产(Nissan)、标致(Peugeot)、雷诺(Renault)、丰田(Toyota)、大众(VW)等多家汽车厂商与非公路设备制造商。

作者:Stuart Birch和Bill Visnic

来源:SAE《汽车工程》杂志

翻译:SAE 中国办公室

Jaguar, Exa say simulation to eliminate prototypes by 2020

Finding the right ratio of "emphasis" (aka "compromise") between design and engineering priorities has long been part of the enduring magic behind the conception and creation of vehicles.

Today's increasingly advanced CAD and CAE software solutions have arguably eased this tension and reduced the longstanding conflict to more of a mere tussle, but now it's going a step further: Jaguar Land Rover (JLR) and its close partner, simulation-software expert Exa Corp., say design software has become so sophisticated that by 2020 they can eliminate the need to build physical prototypes of a new vehicle under development.

At later stages of development, there always will be the need for driveable prototypes, of course. But the two companies said Exa's integrated visualization tools—and Jaguar's decade-plus of focused experience in applying them—create a technology platform for state-of-the-art, simulation-driven development that they project can eventually eradicate prototypes.

Jean-Paul Roux, Paris-based President of European Operations for Exa, explains: “Carmakers that utilize visualization modules integrated within CAE software, such as Exa PowerFLOW, are beginning to reap the benefits of immersive, photorealistic rendered representations of every stage of the design process.”

Long gone are the days of “stock” presentation software for communicating intricate and continually changing design phases as carmakers “step into the future,” he asserted.

He emphasized, for example, that gaining a clearer understanding of which design feature impacts which area of aerodynamic performance on a vehicle plays an integral part in creating a more open discourse between the design studio and engineers: “This allows both parties to undertake the creative process with one another’s priorities and objectives in mind, actually resulting in bolder and more expressive design concepts with greater aerodynamic capabilities.”

Roux added that large-scale, latent- or minute-flow dynamics now can be detected to what he terms “the utmost degree of accuracy” with these sophisticated visualization tools—and such intricate views are not available in the wind tunnel: “This provides design and engineering teams with a level of insight into their conceptual alterations, in real-time, which revolutionizes what components look like and how they are created.”

JLR used Exa’s system for the XE, which particularly helped to achieve excellent aerodynamics (a best Cd figure of 0.26) without requiring excessive styling compromises. In what may amaze many rivals, JLR did not use a single physical aerodynamic prototype during development of the XE — all aerodynamic optimization was done exclusively through Exa PowerFLOW simulation, Ales Alajbegovic, Exa’s Vice President of Ground Transportation Applications, told Automotive Engineering.

Mark Stanton, JLR’s Director of Special Vehicle Operations (SVO) and formerly its Director of Vehicle Engineering, said, “We use Exa for all of our current-production vehicles to work on development the aerodynamic properties of those vehicles. Another example is the F-Pace (crossover). Here we use Exa to achieve perfect lift balance—you have seventy 'counts' of lift on the front and rear, which really contributes to the sporty driving experience of the vehicle.

“We've also used it [Exa simulation software] to help improve the aerodynamic drag,” Stanton continued. "We have apertures in the front bumper which we use to turn the airflow around the front corner to really improve the aerodynamic efficiency of the vehicle.

"All of this," he said, "was done in the virtual world before we ever had any physical properties. We really only validated with a physical (prototype) right at the end of the process, as we have all of the confidence in these virtual tools."

Aligning design with engineering

Paul Stewart, Exa’s Design and Visualization Director at the company’s Burlington, Massachusetts, headquarters, added that when working on different timescales—perhaps with conflicting objectives—it had not been uncommon for designers and engineers to find themselves out of sync when working on the same project, particularly when day-to-day contact may be limited.

“What some carmakers have now discovered, however, is that simulation-driven design can help repair this disconnect thanks to integrated visualization tools provided in CAE software such as Exa PowerFLOW.”

Stewart said that for both designers and engineers, simulation software provides an “intricate” real-time understanding of design alterations: “This doesn’t mean that designers are now having to concede ground on more daring projects—quite the opposite, as this holistic approach to design encourages multidisciplinary collaboration right from the start of the development process, resulting in expressive yet feasible designs.”

Beyond aerodynamics to full-vehicle validation

Jaguar is confident about its 2020 timeframe for eliminating prototype builds largely because its decade of collaboration with Exa has generated an "evolution" of prototype reduction, starting with the elimination of earliest prototype phases, said the Exa spokesperson.

Stanton confirmed the company is aiming to achieve full-vehicle verification exclusively through digital simulation by 2020, going straight from virtual into the final physical production vehicle: “The use of Exa software now is really key in what we do at Jaguar Land Rover. We used over 36 million hours of CPU time in 2014 on Exa and that’s the equivalent of about 7000 physical wind tunnel tests, so that’s pretty immense!”

He added: “We are trying to ‘left shift’ (from physical) our engineering, and virtual engineering is absolutely a key part of that shift. It enables us, far earlier, to validate that we have met all requirements for the program and ensure that we have the quality baked in right up front.”

Meanwhile, Exa’s Alajbegovic asserted that full-vehicle verification by simulation likely will generate immense cost and time reductions in the product-development process.

“The most significant cost savings when an automaker commits to virtual design comes from avoiding late changes and fixes,” he said. “Late-discovery and fixes that prompt a one- or two-month delay of the market launch can cost an automaker hundreds of millions of dollars. Problems requiring tooling changes also cost several million dollars. (Improved) ability to design vehicles on cost and time will be enabled using virtual design.”

Apart from process savings, reducing or eliminating prototypes also will have a significant bottom-line impact, Alajbegovic added. “Considering just the prototype vehicle costs (not including testing costs), static clay models may cost between $500,000 to $1 million per unit and traditional automakers may build two or three models for early testing,” he said. “Drivable prototypes may cost between $500,000 - $1 million per unit (depending on the carryover versus prototype-parts content), with automakers building between 100-200 driving prototypes for physical tests.”

Roux opened the company’s Paris office in 2002, further expanding the company’s client list. Together with JLR, that lineup now includes BMW, Delphi, Denso, Fiat Chrysler, Ford, Honda, Hyundai, Nissan, Peugeot, Renault, Toyota, VW and major commercial vehicle and off-highway companies.

Author: Stuart Birch & Bill Visnic

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Stuart Birch 和 BillVisnic

- 行业:汽车

- 主题:工程设计与造型