美国韦恩州立大学的CHARM 10.0人体模拟系统,能够在内脏和身体组织的层面模拟人体在汽车碰撞中的情况。

美国韦恩州立大学的CHARM 10.0人体模拟系统,能够在内脏和身体组织的层面模拟人体在汽车碰撞中的情况。 密歇根州沃伦市,通用汽车工程师正在讨论CAE模拟的结果,这种模拟可以准确描述2015款Trax的结构和各个元件在碰撞中的表现。

密歇根州沃伦市,通用汽车工程师正在讨论CAE模拟的结果,这种模拟可以准确描述2015款Trax的结构和各个元件在碰撞中的表现。 美国维克森林大学的研究员借助丰田的THUMS 4.0系统,建立了人体腰椎在正面碰撞中的受力模型。

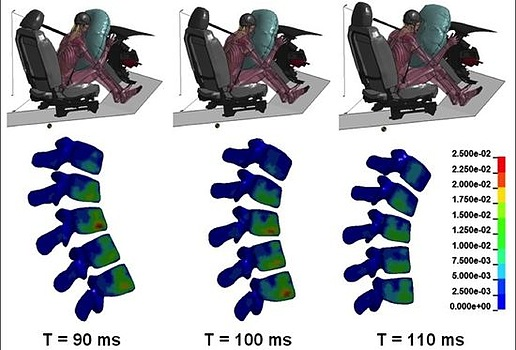

美国维克森林大学的研究员借助丰田的THUMS 4.0系统,建立了人体腰椎在正面碰撞中的受力模型。 丰田THUMS 5.0系统建立的模型可以反映乘客在碰撞发生前的不同姿势和肌肉张力水平。

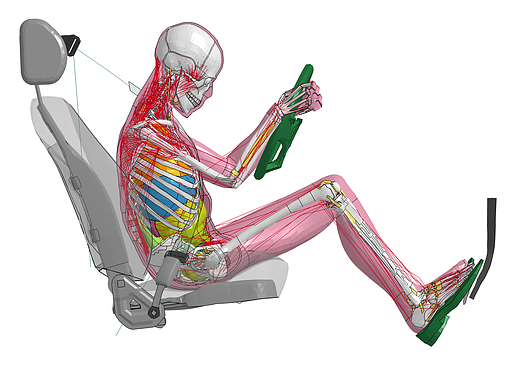

丰田THUMS 5.0系统建立的模型可以反映乘客在碰撞发生前的不同姿势和肌肉张力水平。

车祸的发生往往就在一眨眼的工夫,而在这关键的一刹那间,碰撞产生的力将如何穿过车身,作用于车内人员身上?要想打造更加安全的汽车,了解这些细节信息至关重要。

数十年来,在通用汽车(General Motors)位于密歇根州的米尔福德试车场(Milford Proving Ground),以及其他汽车生产商的试车跑道上,为了给汽车安全工程师提供更多关键数据,碰撞测试中的假人必须忍受无数次强烈碰撞的冲击。通用实验室工程集团经理、技术专家Jack Jensen表示,这种人们熟知的靶心假人由钢材、橡胶、乙烯和泡沫等材料组成,经过年复一年的发展,已经变得越来越成熟。

Jensen表示,如今的碰撞假人中安装了各式各样的最新仪表,从本质上已经成为了一种移动数据记录器,就好像是一个人体形状的黑盒子。过去的假人可能还会受到各种仪器连接线的限制,但最新的假人已经采用了各类无线独立传感器,完全可以实现自由移动。“这种新型假人拥有140个数据通道,可以达到每毫秒10个样本的传送速度,很快就能积累大量数据。”

首美安全系统设备(Humanetics Innovative Solution)公司位于密歇根州的普利茅斯市,是一家处于领先地位的拟人测试设备(ATD)供应商。

Jensen解释说,如今的ATD设备中装满了加速器、测力传感器、角速度传感器和位移计,可以承受“极大的加速度和负载,并实现毫米级别精度的形变控制。”举例而言,“我们可以通过测试胸腔的压缩程度或胸骨与脊椎之间的距离变化”,判断假人的形变情况。这些数据可以帮助工程师预测,车上人员可能会在真实碰撞中受到何种程度的伤害。

Jensen继续说,“我们大约拥有190到200个不同尺寸、形状,代表年龄不同的碰撞测试假人。”这些假人并不便宜,单个价格可能超过12万美元,有的甚至可能高达50万美元。

数字化假人

Jensen表示,如今,越来越多的汽车厂商都开始进行虚拟碰撞测试,数字化假人也在虚拟碰撞测试中日益流行起来。这种模拟碰撞测试主要利用CAD(计算机辅助设计)和CAE(计算机辅助工程)系统进行有限元建模,可以在真正开始硬件制造之前,帮助工程师在早期设计阶段获得更多信息,并最终通过一系列测试案例,逐步优化车辆性能。

Jensen指出,“不过,在米尔福德,我们仍会进行大量实际的碰撞测试。”这是由于虽然虚拟碰撞测试可以验证模型、确认对系统性能的预测,或在系统功能尚未定型的情况下发挥作用,但并无法捕捉到真实碰撞中的所有细节,而且ATD设备也很难测量到所有数据,因此通用汽车并不会完全用虚拟测试替代实际测试,真实假人和虚拟假人都能在这里发挥作用。此外,由于政府的相关安全条款是根据真实碰撞测试制定的,因此通用汽车还会用软件为真实假人的表现建模。

“我们可能会进行一次物理碰撞测试,了解车辆或车辆安全系统在碰撞中的表现。”他说,“接着我们就可以通过大量计算机模拟,比如说20次模拟,进行一系列渐进式优化,并最终打造出新的最优化车型,或最优化的系统,用于进行下阶段的真实碰撞测试。虽然CAE技术能够帮助我们大幅减少分析某一特定情况所需进行的实际碰撞的次数,但我们仍必须不断发现新的危险状况,从而建立新的测试案例,而这意味着需要我们完成的汽车碰撞测试将会越来越多。”

虚拟驾驶员和乘客

2003年,丰田汽车公司(Toyota)推出了一款虚拟人体建模软件THUMS,以供业界使用。汽车安全工程师兼生物医药工程师Jason Hallman表示,这款软件是与丰田汽车中央研发实验室(Toyota Motor Central R&D Lab)联合开发而成,是最受欢迎的汽车乘客安全模拟软件之一。目前,这款软件拥有大约150名用户,主要为汽车厂商、座椅供应商、交通安全研究中心及学术机构等。

“目前,我们的THUMS软件已经开发到4.0版本,是一种可以具体定义各类人体软、硬组织的有限元模拟工具,可以细致到骨头、器官、肌肉、韧带和肌腱等。”Hallman表示,“这样一来,建立一个模型可能涉及200万个要素。”

美国维克森林大学(Wake Forest University)正是THUMS 4.0的学术机构用户之一,“我们重新构建了大约11起造成急性伤害的汽车碰撞事故,这里面既有正面碰撞,也有侧面碰撞。”该大学生物医药工程系助教Ashley Weaver表示,“通过模拟真实车祸情况,我们可以研究汽车的设计参数、安全功能及乘客因素在事故中发挥的作用,并借此提高车辆的安全性。”

丰田专攻生物力学的高级首席工程师Steve Ham表示,THUMS系统支持三种体型分类,即高大男性、中等身材男性和较小身材女性,而CHARM 10.0版本还可以提供另外两种分类,即幼儿和老年女性。

“大体而言,CHARM 10.0版本的技术背景与THUMS软件差不多,”Ham表示,“但你确实需要专门的儿童和老人模型,因为他们的身体形状和组织构成与成年人并不相同。”他说,10岁儿童头部与躯干之间的比例肯定与成人不同,而且他们的盆骨也并未完全闭合,而70岁的妇女则一般会有骨质疏松的情况。

可以看到,碰撞测试需要更多不同类型的身体分类,但建立一个模型可能耗时数年。因此,Hallman和他在密歇根大学(University of Michigan)的团队正在开发一种可以加快建模速度的新方法。Hallman的团队借助人口调研中的身体数据统计,通过数学方法改变现有的有限元骨骼与组织模型,从而使其覆盖更多体型和尺寸。(见http://papers.sae.org/2016-01-1491/ 点击原文直达)

Ham指出,对细节的控制越有力,工程师就能够针对更多乘员身材类型的需要,对车辆的安全气囊、座椅安全带和被动安全等系统进行更加具体的调整。同理,THUMS 5.0版本可以针对车内乘客处于无准备的放松状态或,或是做好准备的不同情况,更好地模拟乘员身体形态和肌肉状态,从而提供更有针对性的撞后伤亡分析,因而也能为汽车安全设备的评估提供更多帮助。

作者:Steven Ashley

来源:SAE《汽车工程》杂志

翻译:SAE 上海办公室

Digital dummies in virtual collisions augment traditional crash tests

A car crash takes half a blink of an eye. Detailed knowledge of the crucial split-second when the crash impact energy flashes through a vehicle’s body and then onto the occupants’ bodies is critical to building safer cars.

For decades at automakers’ test tracks such as GM’s Milford Proving Ground in Michigan, crash test dummies have endured repeated near ballistic collisions to provide that key data to safety and vehicle engineers. Through the years, the familiar bull’s-eyed manikins of steel, rubber, vinyl, and foam have grown increasingly sophisticated, said Jack Jensen, Engineering Group Manager at the lab and GM Technical Fellow.

Fitted with the latest instrumentation, crash dummies have essentially become flight-data recorders, black boxes in human form, as the sensors and transducers are now self-contained and wireless, whereas previous dummies needed cables that could restrain free movement, Jensen said. “The new dummies can have 140 channels of data delivering at a rate around 10 samples a millisecond, which quickly fills huge files.”

Humanetics Innovative Solution of Plymouth, MI, is the leading supplier of anthropomorphic test devices, or ATDs.

ATDs are fitted with accelerometers, load cells, angular rate sensors, and displacement gauges, which “gives you so many g’s, so many Newtons of load, millimeters of deflection,” he explained. The deflection numbers, for instance, “let us measure the compression of the chest cavity or distance between the sternum and spine.” These metrics help define injury criteria for predicting the statistical risks of injuries.

“We have about 190 to 200 crash-test dummies in a wide range of sizes, shapes, and ages,” Jensen continued. Dummies are not cheap; they can go for $125,000, even a half-million dollars a copy.

Digital dummies

More and more at the automakers nowadays, digital crash test dummies made of zeroes and ones are taking the big hits in virtual vehicles, he said. The simulated crash tests using computer-aided design (CAD) and engineering (CAE) systems to do finite element modeling and analysis allow GM engineers to learn earlier in the design process, before the hardware is available and built, and also optimize the performance across a broad range of test conditions.

“We still do a lot of physical crash tests here at Milford,” Jensen noted. The collisions are used to validate the models, confirm performance predictions, or when system capabilities are still evolving. Real dummies will be needed because simulations fail to capture everything that happens in a crash test or that an ATD can measure, so GM uses both physical and virtual dummies. They also use the software to model the behavior of physical dummies themselves because governments define safety regulations according to real-world crash tests.

“We might run a physical crash test to get a baseline regarding how the vehicle or safety system performs,” he said. “Then maybe we’d implement a series of incremental improvements using say, 20 computer simulations, and finally, build the new optimized vehicle or system for testing. But even though CAE allows us to reduce the number of physical collisions for analyzing a given engineering condition, the constant search for new hazardous conditions to consider means we’re doing more vehicle crashes than ever before.”

Virtual drivers and passengers

In 2003, Toyota introduced for public use the Total Human Model for Safety (THUMS) virtual human model software. THUMS, which was co-developed withToyota Motor Central R&D Labs, is the most popular vehicle passenger safety simulation, said Jason Hallman, a vehicle safety engineer and biomedical engineer. The software today has 150 users and licensees including automakers, seat suppliers, research transport safety centers, and academic institutions.

“Right now we’re on THUMS v. 4, which is a finite-element physical framework in which the body’s hard and soft tissues—the bones, organs, muscles, ligaments, tendons—have been simulated in detail,” Hallman said. “The result is a model with 2 million elements.”

One of the academic institutions that uses THUMS 4 is a team of modelers at Wake Forest University: “We’ve reconstructed about eleven motor vehicle crashes—both frontal and side impacts—that caused acute injuries,” said Ashley Weaver, Assistant Professor of Biomedical Engineering. “By simulating real-world crashes, we can study the effect of vehicle design parameters, safety features, and occupant factors to improve safety.”

The THUMS system models three body categories: a large male, a medium man, and small woman, whereas two other classifications—young child and elderly female—are simulated by Collaborative Human Advanced Research Models v. 10 (CHARM 10), said Steve Ham, Toyota Senior Principal Engineer, who focuses on biomechanics.

“The technical background behind CHARM 10 and THUMS are substantially the same,” Ham said. “But you need specific models to represent children and the aged because their body geometries and the materials properties of their tissues are not the same as those average adults.” For a 10-year-old, the head-to-body ratios are different and the pelvic bone still has a weakness, a gap in it, he said. A 70-year-old woman typically has osteoporosis.

More specialized body types are needed, but because it can take several years to build one, Hallman and a team at the University of Michigan are developing a way to produce them quicker. Using body data from population studies, they mathematically morph existing finite-element models of skeletons and whole bodies across multiple body sizes and shapes. (See http://papers.sae.org/2016-01-1491/)

The greater scalability of the details would let engineers better fine-tune airbags, seatbelts, and passive safety systems to a wider range of bodies, Ham noted. Likewise, THUMS 5, which is being readied for release, will help evaluation of safety equipment by enabling more detailed analyses of post-crash injuries because it better simulates the body attitude and muscular state of a vehicle occupant when relaxed or braced for impact.

Author: Steven Ashley

Source: SAE Automotive Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Steven Ashley

- 行业:汽车

- 主题:噪声、振动与声振粗糙度质量、可靠性与耐久性安全性人体工程学/人因工程学工程设计与造型测试与检验