Aerion预计将于2016年上半年宣布AS2超音速飞机装配工厂的地址,届时也将正式启动AS2项目。厂区建设将于2018年动工。

Aerion预计将于2016年上半年宣布AS2超音速飞机装配工厂的地址,届时也将正式启动AS2项目。厂区建设将于2018年动工。 自2014年建立合作关系以来,Aerion和空客集团的工程师一直致力于飞机结构和系统的合作设计。空客旗下的D&S公司主要负责机身结构、数字飞行控制、综合燃油系统和起落架系统的设计工作。Aerion负责其他系统的设计,包括航电设备、环境控制、辅助动力、液压、电气系统、机舱设施等。空气动力学和飞行科学的相关研发工作则由双方共同进行。

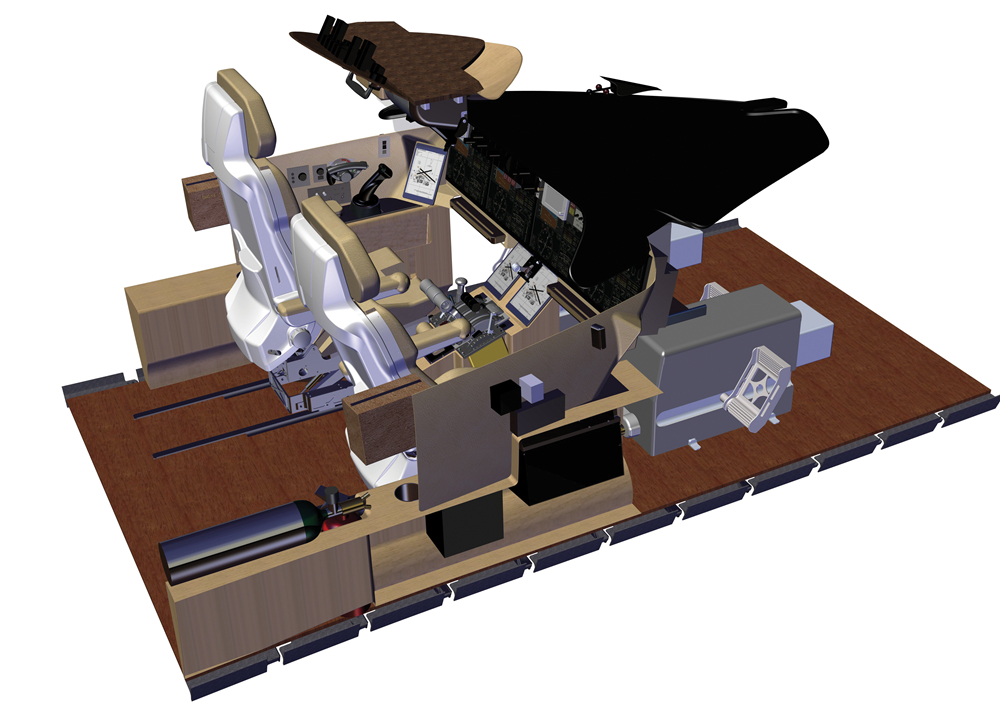

自2014年建立合作关系以来,Aerion和空客集团的工程师一直致力于飞机结构和系统的合作设计。空客旗下的D&S公司主要负责机身结构、数字飞行控制、综合燃油系统和起落架系统的设计工作。Aerion负责其他系统的设计,包括航电设备、环境控制、辅助动力、液压、电气系统、机舱设施等。空气动力学和飞行科学的相关研发工作则由双方共同进行。 AS2驾驶舱将采用先进的航电设备,充分运用自然视线技术和人体工学知识,旨在实现飞行状态感知的最佳水平。在驾驶舱中,Aerion还将仔细研究日间/夜间照明等问题,致力于打造出与客舱环境同样卓越的驾驶舱环境。

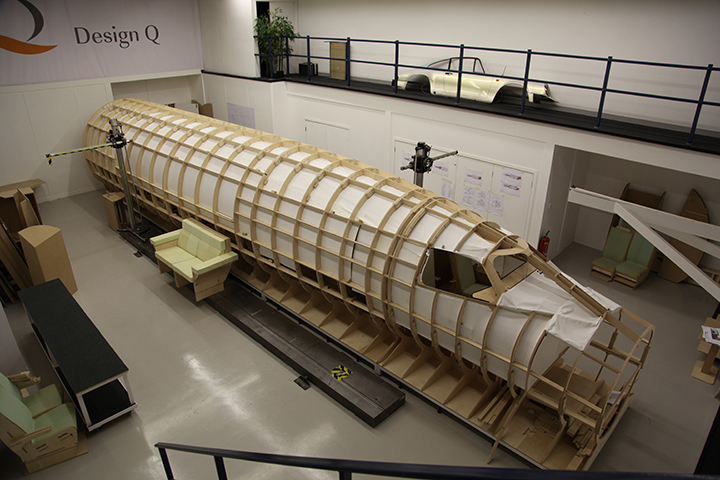

AS2驾驶舱将采用先进的航电设备,充分运用自然视线技术和人体工学知识,旨在实现飞行状态感知的最佳水平。在驾驶舱中,Aerion还将仔细研究日间/夜间照明等问题,致力于打造出与客舱环境同样卓越的驾驶舱环境。 AS2驾驶舱和机舱设计的全尺寸工程模型,由英格兰的雷迪奇的Design Q公司完成。

AS2驾驶舱和机舱设计的全尺寸工程模型,由英格兰的雷迪奇的Design Q公司完成。 AS2驾驶舱和机舱设计的全尺寸工程模型,由英格兰的雷迪奇的Design Q公司完成。

AS2驾驶舱和机舱设计的全尺寸工程模型,由英格兰的雷迪奇的Design Q公司完成。 AS2的技术规格

AS2的技术规格 Aerion AS2的机舱初步效果图,由INAIRVATION和Design Q-Night完成。

Aerion AS2的机舱初步效果图,由INAIRVATION和Design Q-Night完成。 Aerion AS2的机舱初步效果图,由INAIRVATION和Design Q-Night完成。

Aerion AS2的机舱初步效果图,由INAIRVATION和Design Q-Night完成。 Aerion首席执行官Doug Nichols说:“我们计划在2016年上半年选定推进系统。这样项目很快就可以正式启动。”

Aerion首席执行官Doug Nichols说:“我们计划在2016年上半年选定推进系统。这样项目很快就可以正式启动。” 空客与Aerion自2014年首次合作组建工程队伍以来,一直致力于打造1.5倍音速的AS2机型,双方的合作“低调但却进展稳健”。

空客与Aerion自2014年首次合作组建工程队伍以来,一直致力于打造1.5倍音速的AS2机型,双方的合作“低调但却进展稳健”。 Aerion表示,AS2飞机可以满足当前的法规要求,并实现高效运行,飞机也符合陆地上空超音速飞行的相关规定。

Aerion表示,AS2飞机可以满足当前的法规要求,并实现高效运行,飞机也符合陆地上空超音速飞行的相关规定。

自2014年起,Aerion和空客集团开始合作进行AS2超音速公务机的研发。这一合作正越来越引人注目, Flexjet于2015年11月中旬宣布,将订购20架AS2飞机,这是该项目接到的首笔确定订单。

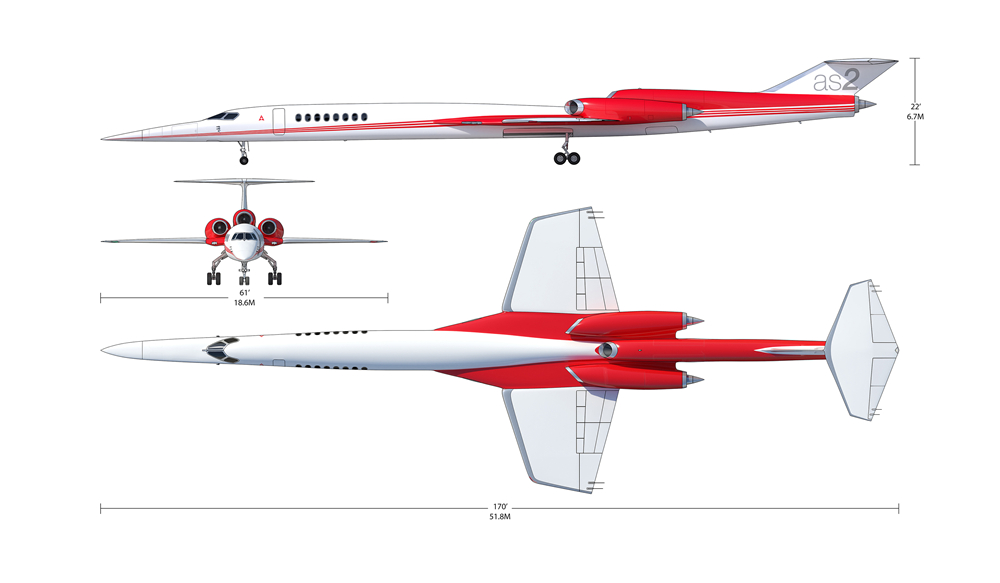

AS2可容纳8到12名乘客,在超音速模式下洲际航程将达4750海里。与亚音速飞机相比,AS2飞越大西洋的时间可以缩短3小时,而横跨太平洋的时间则可缩短6个多小时。预计这款三引擎飞机将于2021年首飞,并于2023年投入使用。

Flexjet的主要提供小型喷气机运营和租赁服务,公司董事长Kenn Ricci 称:“我们认为,Aerion的先进技术和AS2飞机的高性能有望改变整个商务机市场。” Aerion和 Flexjet将共同为AS2飞机设计内饰。

空客与Aerion自2014年首次合作组建工程队伍以来,一直致力于打造1.5倍音速的AS2机型,双方的合作“低调但却进展稳健”。

西班牙的空客D&S(Airbus Defense & Space)公司负责设计AS2的机身构造、电传飞控系统、综合燃料系统和起落装置,他们的工作也取得了一定进展。目前已经完成初步设计的部分包括10翼梁碳纤维机翼结构、机身和尾翼结构、接合型主起落架系统(该起落架收起时可以最大程度地节省机身空间),以及采用了数字化线传飞控(fly-by-wire)技术的燃油系统,可以更好地控制重心。

AS2的飞行控制设计将会利用其体积小功能强大的执行器集成入AS2纤薄的飞行表面中。为了支持整个设计过程,空客D&S制作了一个钛金属机翼前沿部分的样板,用于进行评估。同时,公司正在对复合材料样品进行测试,希望进一步优化材料性能。

Aerion主要负责其他系统的研发工作,包括航电设备、电气系统、环境控制、液压和辅助动力等等。Aerion与空客D&S公司对各个系统进行了初步的空间分配,充分考虑了机身重量和平衡等因素。候选供应商名单已经确定,现已进入甄选阶段。

去年9月,来自Aerion、空客D&S、空客集团以及其他一级供应商的高级工程人员来到位于内华达州里诺市的Aerion总部,进行了为期4天的技术和项目评估,内容涵盖飞机结构飞机系统方面目前已完成的所有工程设计。

“本次设计评估结果证明,经过过去一年的努力,我们已经由概念设计阶段进入Aerion技术商业化的阶段,”Aerion飞机研发高级副总裁Mike Hinderberger表示,“目前我们正在进行工程设计,到2020年左右,将会实现超音速飞机的制造与飞行。”

就目前的情况来看,发动机研发进展将决定AS2机型2021年是否能顺利首飞。飞机最初设计时所选择的是普惠公司(Pratt & Whitney)的JT8D引擎,但工程师们正在寻找更先进的发动机。

Aerion首席执行官Doug Nichols表示:“我们的目标是在2016年上半年选定推进系统,这样项目很快就可以正式启动。”

Aerion已经选定了适合改装的核心发动机,在改装后可以满足超音速飞行的要求。

“我们会继续进行发动机的研发工作,致力于通过最小的改动满足需要达到的性能要求,”Nichols表示,“目前,Aerion正努力寻找一种解决方案,既能达到4级噪声标准,又能保持远距离超音速飞行的要求。对于低双路式涡轮喷气式超音速发动机来说,这是个巨大挑战。但现今的发动机技术应该可以让我们找到好的解决方案。”

Aerion表示,AS2飞机可以满足当前的法规要求,并实现高效运行,飞机也符合陆地上空超音速飞行的相关规定。这得益于AS2的优良性能——飞机可以以接近音速的速度(0.95-0.98马赫)高效运行;在允许超音速飞机飞行的水面上空以及其他区域,飞行速度最高可达1.5马赫(音速的1.5倍)。“无论在亚音速飞行还是超音速飞行模式下,飞机的表现都十分优秀,”Hinderberg表示,该机型“更像一架战斗机,而非商务机。”

在合作之初,空客对Aerion的层流分析软件工具表现出了浓厚兴趣。该工具可用于分析高速气流,优化机身。Hinderberg表示,事实上,合作项目的“首要目标就是对自然层流和波阻带来的影响进行优化。”

“飞机和研发项目主要由Aerion负责,但空客集团也获益良多,”空客集团战略与企业发展部门高级副总裁Ken McKenzie表示,“我们掌握了新型的技术和工具。通过合作,我们获得了更丰富的工程和制造工艺知识,比如数字制造技术等。AS2项目将成为创新设计、创新工程和创新制造的孵化器。”

Nichols表示,“Aerion已经正式开始在美国为AS2的生产工厂选址。”

Nichols说:“目前,我们正在寻找一个最理想的厂区,其中需要一个面积100英亩以上的机场以及长度在9000英尺以上的跑道,同时还要满足一些特殊地理条件要求。”其中的一个条件是,在该地点200海里以内有一个适合超音速飞行测试区,如果是在海上则更优。

Aerion还将评估多方面因素,包括机场的适合程度、公路和铁路基础设施、到达运输大型结构和设备所需的深水港的距离、当地的航空产业劳动力水平、国家和地方法规,以及当地生活水平及教育水平等。

Aerion预计将于2016年上半年宣布装配工厂的地址,届时也将正式启动AS2项目。厂区建设将于2018年动工。

空客集团将提供飞机主要部件,最后的总装工作由Aerion负责。双方致力于建立一个长期的合作关系,旨在为项目提供持续的技术支持。Aerion也将向空客集团学习专业知识,以支持其新工厂的建立。

作者:Jean L. Broge

来源:SAE《航空工程》杂志

翻译:SAE 上海办公室

Aerion progresses on the AS2 with help from Airbus, and announces first fleet customer

The joint engineering efforts that Aerion and Airbus Group have dedicated to the AS2 supersonic business jet since 2014 has taken on even more importance as it was announced in mid-November that aircraft has received its first firm order for 20 from Flexjet.

Carrying eight to 12 passengers, the AS2 will have an intercontinental-capable range of 4750 nmi at supersonic speed, saving three hours across the Atlantic vs. subsonic aircraft and more than six hours on longer trans-Pacific routes. The three-engine jet will make its first flight in 2021 and enter service in 2023.

“We see Aerion's technology and the AS2's performance capabilities as potential game-changers for business travel,” said Flexjet Chairman Kenn Ricci. Flexjet offers fractional jet ownership and leasing. Aerion and Flexjet will work together to design the interiors for the AS2s

In terms of Airbus and Aerion working together, the two companies have been proceeding “quietly, but steadily” on the Mach 1.5 AS2 since the first joint engineering team meeting in 2014.

Airbus Defense & Space out of Spain has made progress in the engineering of airframe structures, the AS2’s fly-by-wire flight control system, its integrated fuel system, and landing gear. Some of the company’s accomplishments include preliminary designs for a 10-spar carbon fiber wing structure, fuselage and empennage structures, an articulating main landing gear system that minimizes space requirements in the fuselage when stowed/retracted, and a fuel system that is integrated with the digital fly-by-wire system for control of center of gravity.

The aircraft’s flight control design will take advantage of small, powerful actuators that can be housed in the AS2’s thin flying surfaces. To supplement the design process, Airbus D&S built a sample titanium wing leading-edge section for evaluation and is testing composite material specimens to optimize material properties.

Aerion is the lead for other systems, such as avionics, electrical, environmental control, hydraulics, and auxiliary power. In conjunction with Airbus D&S, Aerion had made preliminary space allocations for every system with weight and balance considerations in mind. Candidate suppliers have been identified and the supplier selection process has begun.

This past September, senior engineering staff from Aerion, Airbus D&S, Airbus Group, and other Tier 1 equipment suppliers gathered at Aerion headquarters in Reno for a four-day technical and program review, covering engineering accomplished to date on all structures and aircraft systems.

“The take-away from the design review and the effort this past year is that we have moved out of the conceptual design phase into commercializing Aerion technology,” said Aerion Senior Vice President for Aircraft Development Mike Hinderberger, “We are doing the engineering work today that will allow us to build and fly a supersonic jet at the turn of the next decade.”

As it stands, the engine will be the pacing element for the first flight of the AS2 in 2021. The original design specified the JT8D engine from Pratt & Whitney, and the engineers are now looking at more modern engines.

“We are targeting the first half of 2016 to select a propulsion system, which will enable us to formally launch the program shortly thereafter,” said Doug Nichols, Aerion CEO.

Aerion has identified existing core engines suitable for adaptation to the needs of supersonic flight.

“We will proceed with an engine that allows us to meet our performance goals with the minimum changes required,” said Nichols. “Aerion is focused on an engine solution that meets Stage 4 noise standards while preserving long-range supersonic performance. This is a significant challenge with a low-bypass supersonic engine, but solutions are in sight with today’s engine technology.”

Aerion says the jet will operate efficiently within the current regulatory environment, including rules regarding supersonic flight over land. This takes advantage of the ability of the AS2 to operate efficiently just below the speed of sound at Mach 0.95 to 0.98, and at speeds up to Mach 1.5 over water and other areas where supersonic flight is permitted. “This is a very good airplane at subsonic or supersonic speeds,” said Hinderberg, adding that he considers the aircraft “almost more like a fighter than a commercial airliner.”

When the partnership began, Airbus was particularly interested in Aerion's proprietary laminar flow software tool for analyzing high-speed airflow and for airframe optimization. In fact, said, Hinderberg, the program’s “two top goals were optimizing for natural laminar flow and optimizing for wave drag.”

“This is Aerion’s jet and Aerion’s program, with substantial benefits for Airbus Group,” said Ken McKenzie, Senior Vice President for Strategy and Corporate Development at Airbus Group. “We gain new technology and tools, and through our collaboration will be expanding engineering knowledge and refining processes such as digital manufacturing. The AS2 program will be an incubator for innovation in design, engineering, and manufacturing.”

Nichols says that “Aerion has begun a formal search for a U.S. manufacturing location” for the AS2.

“We’re looking for a state-of-the art campus of more than 100 acres on a major airport with a minimum 9000-ft runway, and other special geophysical requirements,” he said. Among them will be a location within 200 nmi of a supersonic flight test area, most likely one offshore.

Aerion will evaluate numerous factors including: airport suitability, road and rail infrastructure, proximity to a deep-water port for shipped structures and equipment, local aerospace workforce, state and local regulations, quality of life, and regional educational institutions.

The company expects to announce the location of the assembly site in the first half of 2016 upon formal launch of the AS2 program, and break ground in 2018.

Airbus Group will provide major components and Aerion will conduct final assembly. Both companies envision a long-term relationship for ongoing technical support. Aerion will draw on expertise from Airbus Group for establishing the new Aerion production facility.

Author: Jean L. Broge

Source: SAE Aerospace Engineering Magazine

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分