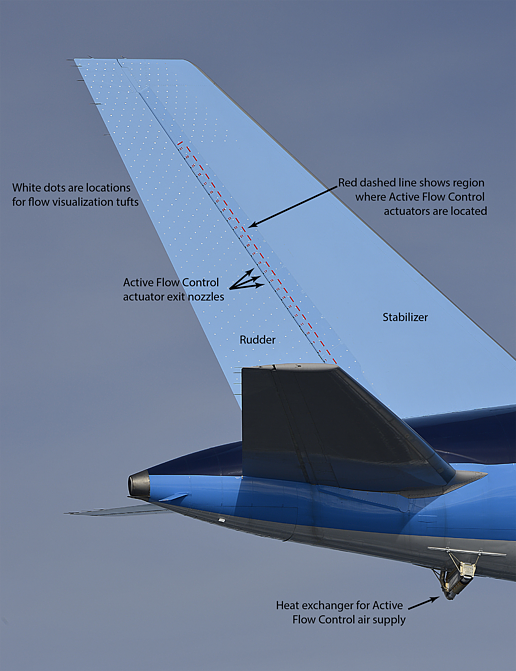

使用在波音757飞机尾翼上的技术,用以测试主动气流控制。(波音/NASA)

使用在波音757飞机尾翼上的技术,用以测试主动气流控制。(波音/NASA) 图中所示波音ecoDemonstrator 757正在飞越华盛顿州的奥林匹克岛。几个月以来,该飞机一直服务于新技术的测试,这些技术有可能提高商用飞机的效率、降低噪音和碳排放。

图中所示波音ecoDemonstrator 757正在飞越华盛顿州的奥林匹克岛。几个月以来,该飞机一直服务于新技术的测试,这些技术有可能提高商用飞机的效率、降低噪音和碳排放。 NASA兰利研究中心的研究人员正在准备即将使用在试飞机翼上的防粘涂层,该飞机将在夏末季节飞越昆虫繁多弗吉尼亚州。

NASA兰利研究中心的研究人员正在准备即将使用在试飞机翼上的防粘涂层,该飞机将在夏末季节飞越昆虫繁多弗吉尼亚州。

这几个月来,波音公司一直在进行ecoDemonstrator 757 的飞行,服务于2015年一批新技术的第一轮评估工作。这些新技术旨在降低自然层流的环境影响,希望在提高空气动力效率的同时,降低噪音与二氧化碳排放水平。

波音对ecoDemonstratror 757 机型的左翼进行了改造,专门用于对波音的未来机翼设计专利技术进行测试,其中包括与自然层流有关的一些先进技术。本文着重介绍其中的一种可变弧度的克鲁格襟翼,波音将在测试中评估其防止昆虫在机翼前缘积聚的能力。

克鲁格襟翼是一种覆盖在机翼前缘的下行襟翼,其功能是为飞机提供更多的升力。在测试过程中,技术人员使用一台安装于机身顶部的红外摄像机监控流过机翼的气流。飞机将在多种环境与条件下飞行,以确定它们对机翼气流可能造成的影响。

此外,波音还与NASA签订了协议,参与NASA的环境保护型航空项目(ERA)。在协议中波音同意将ecoDemonstrator 757 用于两种新技术的测试。在洛杉矶什里夫波特附近举行的一系列飞行测试中,NASA将在该机型的右翼上测试几种防昆虫附着的涂料,以减少昆虫撞上机翼前缘后留下的残渣。这样做的最终目的是为了在机翼上方的其余部分产生更多可减轻拖拽的层流。有研究显示,保持机翼上方气流顺畅最多可减少6%的燃油消耗。

NASA为飞机右翼提供了应用纳米表面涂层技术的前缘板。该测试将确定这些涂层是否能有效抵御昆虫污染,从而降低相关的阻力和燃耗,测试结果将用于未来机翼设计。尽管昆虫残骸并非大问题,但任何阻断机翼上方平滑气流的因素都会提高阻力。

“更高的阻力意味着更高的油耗,从而导致更多污染物将排向大气。我们项目的目标是研究未来30年内能够降低飞机对环境影响的设计理念与技术,”NASA空气动力研究任务理事会ERA项目经理Fay Collier表示。

NASA兰利研究中心的工程师开发了一系列防粘涂层,并在一个小型风洞和一架NASA兰利喷气机的机翼上进行了测试。他们从中选择了最好的一些涂层产品,用于在ecoDemonstrator 右翼上的测试。

在15次测试飞行中,研究人员将在ecoDemonstrator 757 的机翼前缘上使用几种不同的涂层。首先他们将使用无涂层表面进行测试,建立昆虫积累速率的基准数据。接着他们将移除无涂层板,并安装5种不同的涂层板样本。工程师所关注的测试重点之一是涂层的耐久性,因为涂层板只有在扛得住严苛飞行环境的条件下,才能发挥减少阻力的作用。

“降低1%-2%的燃耗听起来不是很多,”Collier表示,“但在飞机上,降低几个百分点的燃耗就意味着节省下数百万美元的成本,此外还能保护环境免受有害物质的污染。”

在垂直尾翼上,NASA和波音将对主动气流控制系统(AFC)进行测试,该系统可改进方向舵上方的气流,并实现空气动力效率最大化。研究团队安装了31个名为“横扫喷气制动器(sweeping jet actuators)”的小型喷气机,这些装置可以按照实际情况的需要,对流过ecoDemonstrator 757垂直尾翼和方向舵上方的空气进行操纵。飞机的垂直尾翼主要用于在起飞降落时提高稳定性,并增加垂直方向上的控制,这在发动机失灵的情况下尤为重要。但当飞机在高空中巡航时,沉重的垂直尾翼就不是那么必要了。

一支由NASA、波音公司、亚利桑那大学和 Caltechresearchers 研究中心的专家组成的团队曾在NASA的埃姆斯研究中心对一台全尺寸757飞机的垂直尾翼进行地面研究,风洞测试的结果显示,AFC喷气机可提升20-30%的侧向力。研究人员希望飞行测试也可以证明这一结果。如果侧向力提升20%,设计师可以将垂直尾翼缩小17%左右,并最多减少0.5%的燃耗。

工程师认为,从理论上来说,借助“横扫喷气机”不仅可以减少垂直尾翼的体积,还能在起飞降落时产生与大型尾翼相当的侧向力。因此,这一装置不仅能够降低飞机的重量与阻力,还能同时降低燃耗。

“我们的研究人员正在努力开发降低飞机燃耗、噪音和排放的技术。如果能在飞行测试中证明这些理念,那么它们将来在商用机队中应用的可能性就大大提高了,” Collier表示。

在9次飞行测试中,ecoDemonstrator 757 飞机中搭载的仪器将测量AFC增强版垂直尾翼的表现。飞机将尝试各种飞行条件,让研究人员对喷气机在垂直尾翼与方向舵周围增加的侧向力进行评估。这些飞行条件中包括发动机失灵模拟、喷气机的配置更改与气流速度的变化。

除此之外,ecoDemonstrator 项目的工程师还在考虑在六月或者七月进行其他一些测试。届时波音公司将会宣布在以测试为目的租赁出去的ecoDemonstrator 757 上将会进行何种测试。当这些飞行测试结束后,波音将协同机队回收协会(Aircraft Fleet Recycling Association),以及负责出租业务的Stifel公司的飞机财务部,一起以环保的方式完成757飞机的回收。

自2011年ecoDemonstrator项目启动以来,已经为40多个新技术提供了测试平台,除757外,参与测试机型还包括下一代737与787型梦幻客机(Dreamliner)。在该项目中进行测试的技术,都考虑了短期到中期的各种应用,这些技术所处的成熟阶段均不相同。

2012年在ecoDemonstrator 737 飞机上测试的技术,有几个已进入下一个研发阶段,或已根据测试结果进行了调整。在该项目中总共测试了15种技术,其中包括旨在将新737 MAX机型的燃油效率提高1.8%的“先进小翼技术(Advanced Technology Winglet)”中的一些方面。

787机型上测试的一些技术仍在进行未来应用评估。在该项目中进行了使用15%环保型柴油与传统喷气机汽油组成的混合燃料进行的首飞测试,其结果将用于支持在商用飞机上推行环保型柴油的举措。

除了波音公司的专利技术之外,NASA在ecoDemonstrator 合作项目中获得的知识都将向全行业公开。

Boeing’s ecoDemonstrator 757 used to get the bugs out

Boeing is in the midst of several months of flights with its ecoDemonstrator 757 in a first-round effort to evaluate new technologies in 2015 that are expected to reduce environmental effects on natural laminar flow as a way to improve aerodynamic efficiency while reducing noise and carbon emissions.

On the ecoDemonstratror 757, the left wing has been modified to test Boeing-proprietary technologies in support of future wing designs, including advances related to natural laminar flow. Specifically, a variable-camber Krueger shield is being tested to see how well it can block insects from accumulating on the wing leading edge.

A Krueger shield is a flap that comes down over the leading edge of the wing to provide added lift for the plane. During the testing, an IR camera attached to the top of the fuselage will monitor the air flow over the wing. Boeing will be flying through different environmental conditions to study the potential effects that the conditions have on the wing flow.

Boeing is also under contract with NASA's Environmentally Responsible Aviation (ERA) Project to test two technologies on the ecoDemonstrator 757. On the right wing, in a series of flight tests near Shreveport, LA, NASA will test bug-phobic coatings to reduce the residue left by bug strikes on the leading edges of aircraft wings; the goal is to enable more drag-reducing laminar flow over the remainder of the wing. Studies have shown that keeping the flow smooth over a wing can reduce fuel consumption as much as 6%.

NASA supplied leading edge panels for the right wing that incorporate nanotechnology surface coatings. The testing will determine whether the coatings are effective in resisting insect contamination that can result in more drag and greater fuel use for future wing design. While the issue of bug residue might seem small, any disruption in the smooth flow of air over the surface of a wing increases drag.

"Increased drag means increased fuel consumption, which results in more pollutants in the atmosphere. The goal of our project is to develop aircraft concepts and technologies to reduce the impact of aviation on the environment over the next 30 years," said Fay Collier, Manager for the NASA Aeronautics Research Mission Directorate's ERA Project.

Engineers at NASA's Langley Research Center developed and tested a number of non-stick coatings in a small wind tunnel and on the wing of a NASA Langley jet. They selected the best candidates to test on the right wing of the ecoDemonstrator.

During 15 planned flights researchers will install sections of coatings onto the leading edge slats of the ecoDemonstrator 757. First they will establish a baseline using uncoated surfaces, to capture insect accumulation rates. Then they will remove those sections and install samples of the five treated panels. One of the things engineers want to test is how durable the coatings are. Treated surfaces will only be effective as drag reducers if they can withstand the harsh flying environment.

"Solutions to reduce fuel use by one or two percent may not sound like much," said Collier. "But shaving aircraft fuel consumption even a few percentage points can save millions of dollars and help protect the environment from harmful emissions."

On the vertical tail, NASA and Boeing are testing active flow control (AFC) to improve airflow over the rudder and maximize its aerodynamic efficiency. The team installed 31 tiny jets called sweeping jet actuators that can manipulate, on demand, the air that flows over the ecoDemonstrator 757's vertical tail and rudder surfaces. An aircraft’s vertical tail is primarily used to add stability and directional control during takeoff and landing, especially in the event of an engine failure. But when the aircraft is cruising at altitude the same large, a heavy tail is not necessary.

Ground studies by a team of NASA, Boeing, University of Arizona, and Caltechresearchers on a full-scale 757 vertical tail in a wind tunnel at NASA's Ames Research Center showed the AFC jets could increase side force by 20 to 30%. Researchers expect the flight tests to confirm those results. A 20% increase in side force could allow designers to scale-down the vertical tail by about 17% and reduce fuel usage by as much as 0.5%.

Engineers theorized they could reduce the size of the vertical tail by using the sweeping jets to generate the same side force during takeoff and landing that a larger tail does. That would reduce the weight and drag of the airplane and decrease its fuel consumption.

"Our researchers have been working hard to develop technologies to reduce airplane fuel consumption, noise, and emissions. Being able to prove those concepts in flight tests gives them a better shot of getting into the commercial fleet," said Collier.

Instruments onboard the ecoDemonstrator 757 flight test airplane will measure the performance of the AFC enhanced vertical tail in nine flights. During those tests, the plane will fly various maneuvers to evaluate the increase in vertical tail and rudder side force caused by the jets. The maneuvers will include simulated engine failures and variations in jet arrangements and flow rates.

ecoDemonstrator program engineers are reviewing some options for additional tests. This particular set of tests will go well into June, possibly July, and Boeing will announce any additional tests with the ecoDemonstrator 757, which was leased for testing purposes, before then. After the flights are complete, Boeing will work with the Aircraft Fleet Recycling Association and the lessor, Stifel's aircraft finance division, to recycle the 757 using environmental best practices.

Since it was launched in 2011, the ecoDemonstrator Program has tested more than 40 technologies with a Next-Generation 737 and a 787 Dreamliner. The program strives to test technologies over a spectrum from near- to long-term application. All the technologies are at different stages of readiness.

Several technologies tested on the ecoDemonstrator 737 in 2012 have moved to the next phase of development or have been adjusted based on the testing. That program tested 15 technologies including aspects of the Advanced Technology Winglet that is expected to improve fuel efficiency by 1.8% on the new 737 MAX.

Technologies tested on the 787 are still being evaluated for future use. That program included the first flight tests using green diesel in a 15% blend with conventional petroleum jet fuel. The tests will be used to support industry efforts to approve the use of green diesel in commercial aviation.

With the exception of Boeing proprietary technology, NASA knowledge gained in collaboration with Boeing from ecoDemonstrator research will be publicly available to benefit industry.

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分

- 作者:Jean L. Broge

- 行业:航空

- 主题:噪声、振动与声振粗糙度质量、可靠性与耐久性运输系统车辆与性能工程设计与造型测试与检验